Cleaning apparatus, measurement method and calibration method

A calibration method and cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, measuring devices, etc., can solve problems such as difficulty in calibrating measuring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

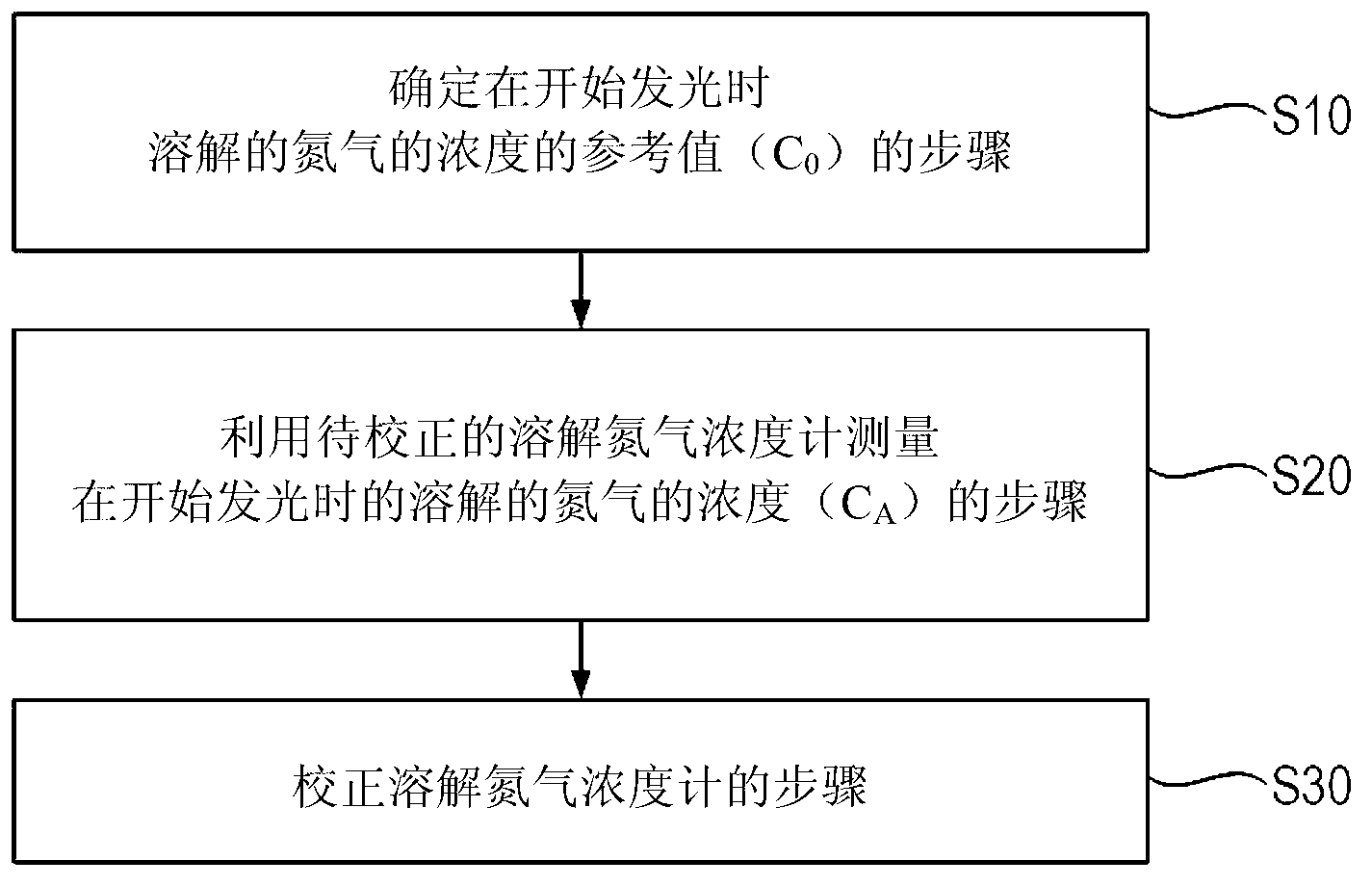

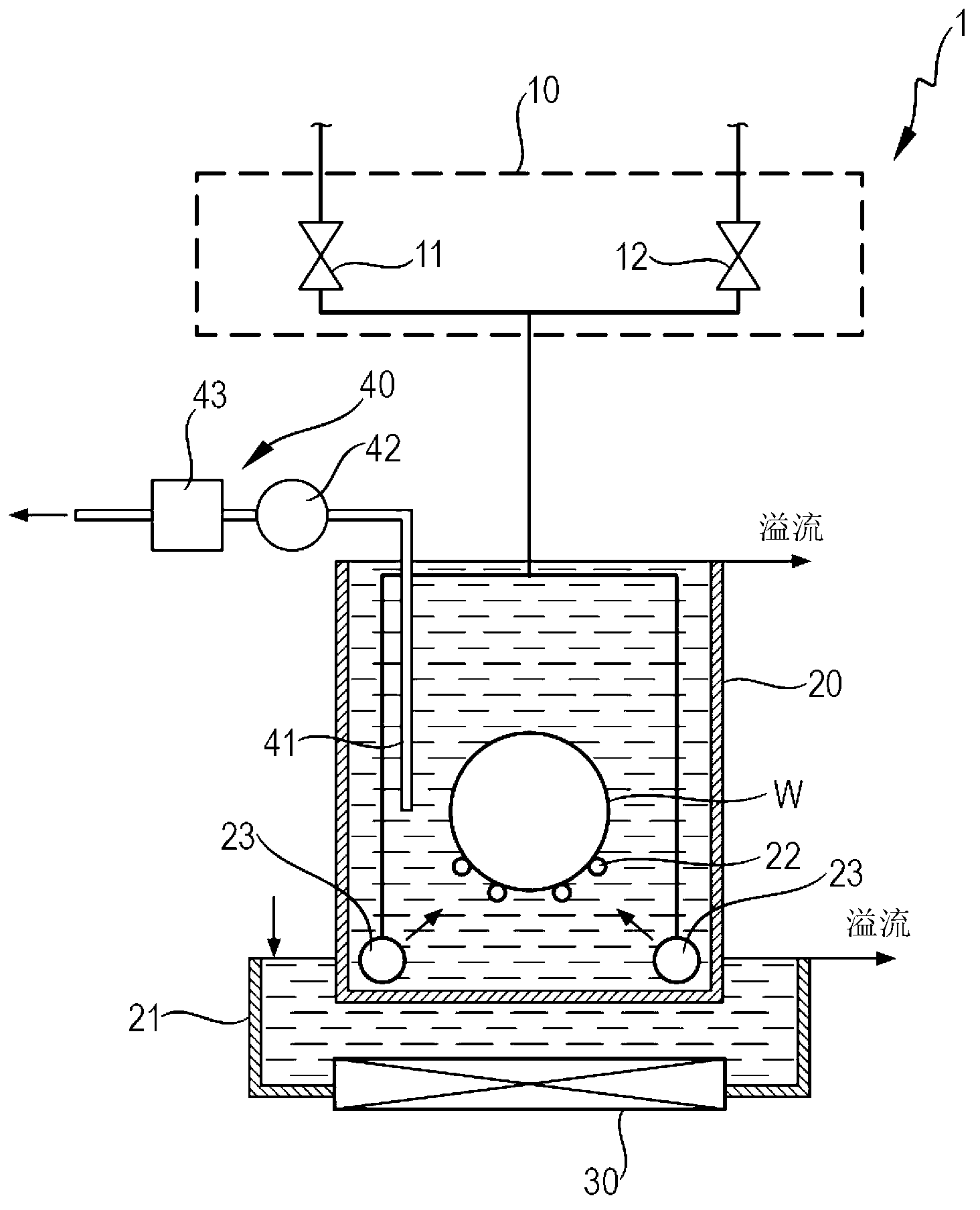

[0053] refer to Figures 1 to 5 A calibration method for calibrating a dissolved nitrogen concentration meter according to the present invention is described. Specifically, for figure 2 In the ultrasonic cleaning device 1 shown, the calibration method according to the invention is a method for calibrating a dissolved nitrogen concentration meter which is the monitoring device 40 .

[0054] Here, if figure 2 As shown, the ultrasonic cleaning device 1 implementing the correction method according to the present invention includes a cleaning tank 20 for keeping a cleaning liquid such as ultrapure water inside, a supply device 10 for supplying the cleaning liquid to the cleaning tank 20, a A connecting tank 21 housing the cleaning tank 20 , an irradiation device 30 provided at the bottom of the connecting tank 21 for irradiating ultrasonic waves, and a monitoring device 40 for monitoring the concentration of dissolved nitrogen in cleaning liquid supplied into the cleaning tank ...

no. 2 approach

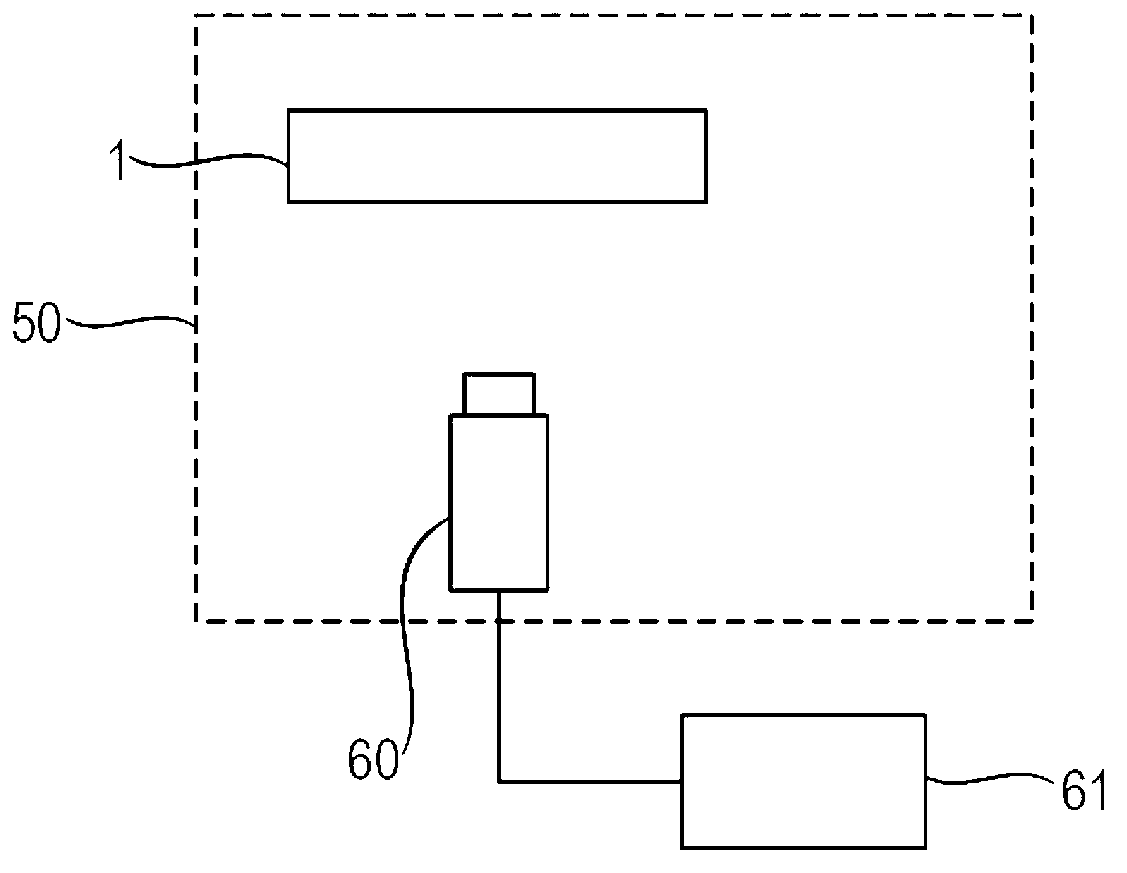

[0083] refer to Figure 6 and 7 A method of measuring the concentration of dissolved nitrogen according to the present invention and a cleaning device according to the present invention are described.

[0084] Such as Figure 6 As shown, in the method for measuring the concentration of dissolved nitrogen according to the present invention, the measuring step ( S110 ) is first performed. Specifically, when having Figure 7 In the cleaning device of the shown device configuration, luminescence was observed for the cleaning liquid in the cleaning tank 20 of the ultrasonic cleaning device 1 . Such as Figure 7 As shown, the cleaning device according to the present invention includes an ultrasonic cleaning device 1 , a dark room 50 , a luminescence detection device 60 , an image processing device 61 and a control device 70 . Such as Figure 7 As shown, the ultrasonic cleaning device 1 is located inside a dark room 50 . A luminescence detection device 60 is also arranged faci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com