Electronic device shell and manufacture method thereof

A technology for electronic devices and manufacturing methods, which is applied to electrical equipment casings/cabinets/drawers, chemical instruments and methods, telephone communications, etc., and can solve problems such as insufficient material hardness, single color, and no longer beautiful and eye-catching appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

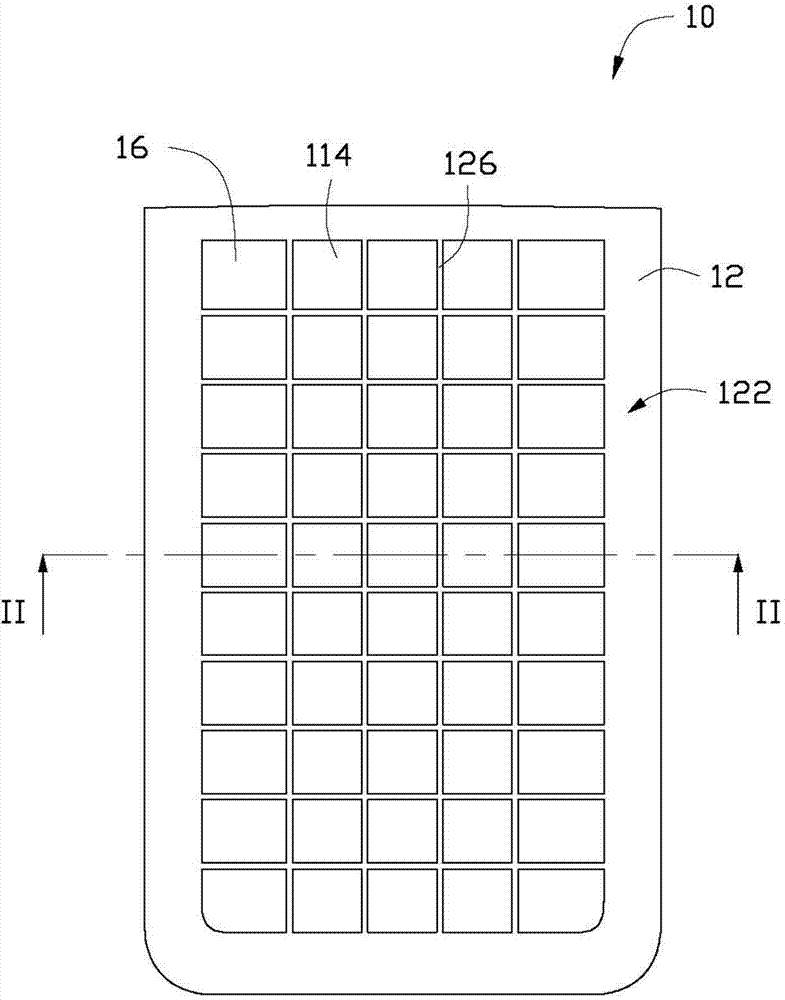

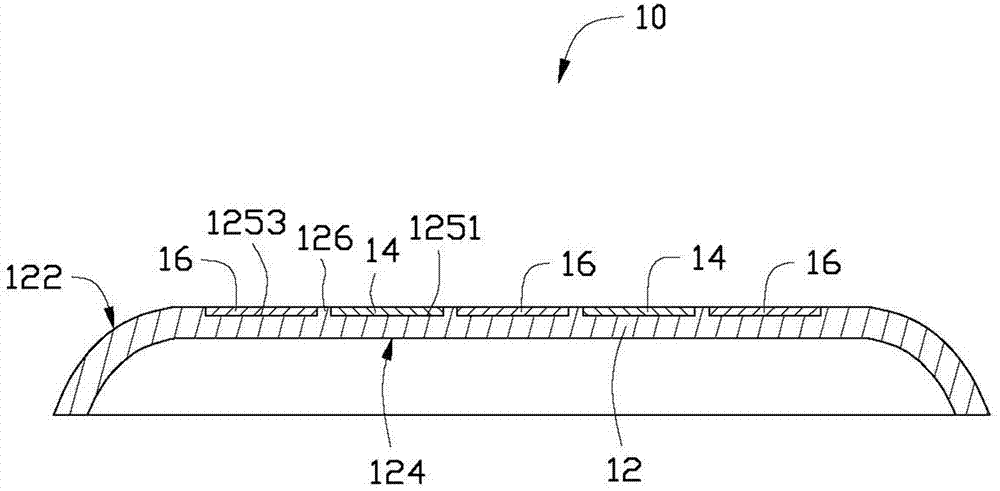

[0021] see figure 1 , the electronic device casing 10 according to the first embodiment of the present invention includes a metal base 12 and a first ceramic coating 14 and a second ceramic coating 16 formed on the surface of the metal base 12 .

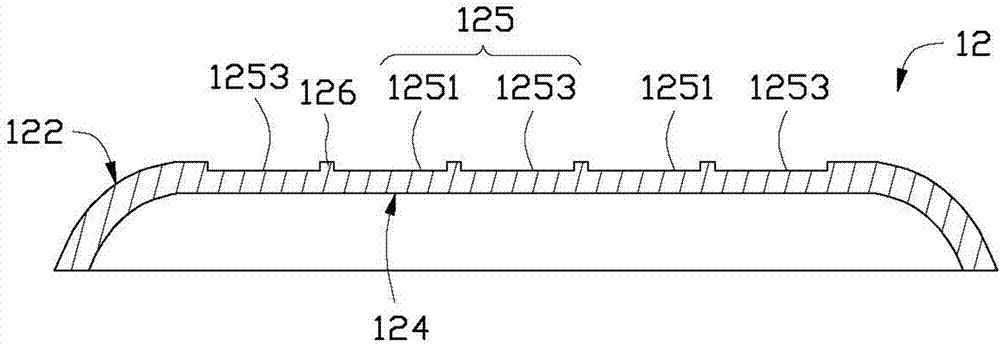

[0022] see figure 2 and image 3 , The metal base 12 can be made of metal such as stainless steel, aluminum alloy, etc., and its thickness is about 0.4~0.6mm, which is 0.5mm in this embodiment. The metal base 12 includes a first surface 122 and a second surface 124 opposite to the first surface 122 . A plurality of recesses 125 and protrusions 126 formed between the recesses 125 are formed on the first surface 122 . The surface of the concave portion 125 is lower than the surface of the convex portion 126 . The surface of the concave portion 125 is a rough surface, and its surface roughness Ra is approximately 1.3-2.0 μm. The concave portion 125 includes several first pattern areas 1251 and several second pattern areas 1253 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com