Electric shock absorbers for motor vehicles

A technology for shock absorbers and motor vehicles, applied in liquid shock absorbers, springs/shock absorbers, mechanical equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

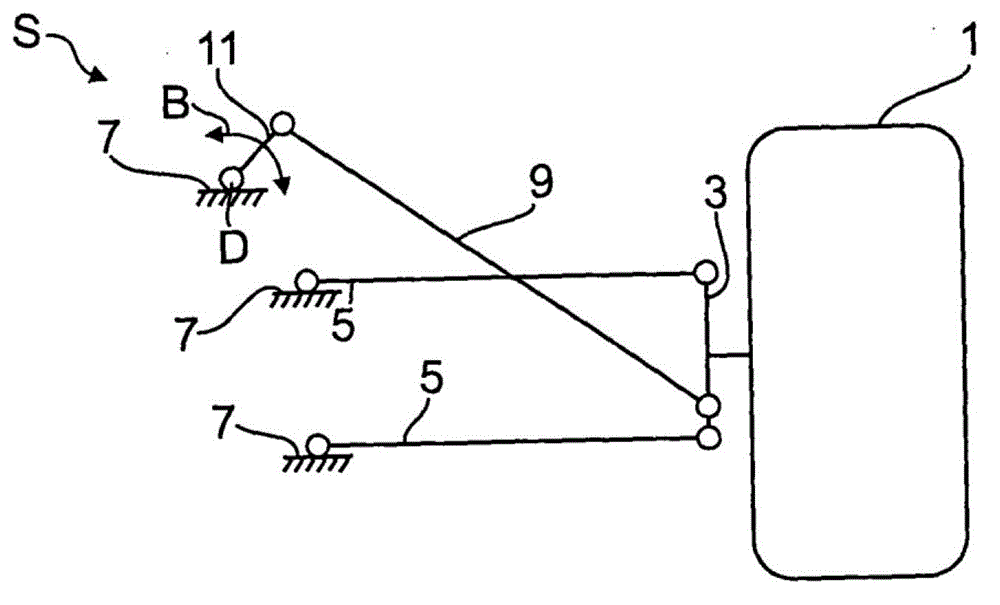

[0024] figure 1 shows a wheel suspension for a wheel 1 of a motor vehicle. The wheel 1 is rotatably supported on a hub carrier 3 . The hub carrier 3 is articulated to the motor vehicle body 7 via a transverse control arm 5 . In addition, the tilt control arm 9 acts on the hub carrier 3 , which is connected to the motor vehicle body 7 via a coupling 11 . exist figure 1 In this case, the coupling 11 is connected to the motor vehicle body 7 in an articulated position S in a rotationally articulated manner about the pivot axis D.

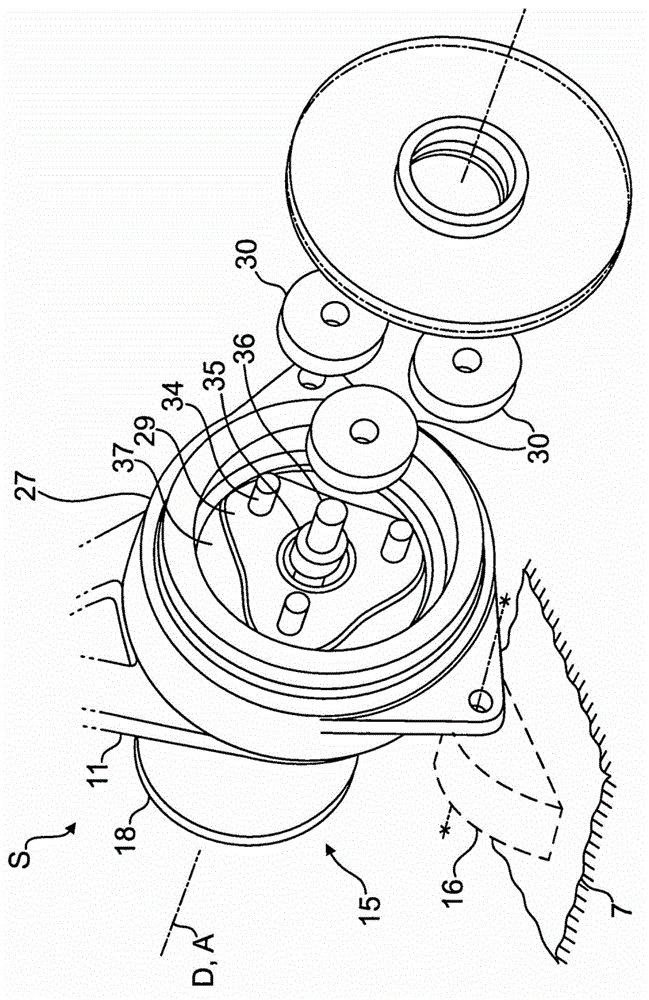

[0025] exist figure 2 In , the articulation point S between the coupling 11 and the motor vehicle body 7 is enlarged and shown in a partially exploded view. The coupling 11 has a fastening eye 13 which is fixed via an electric shock absorber 15 on a retaining bracket 16 shown only in dashed lines, like figure 2 as shown in.

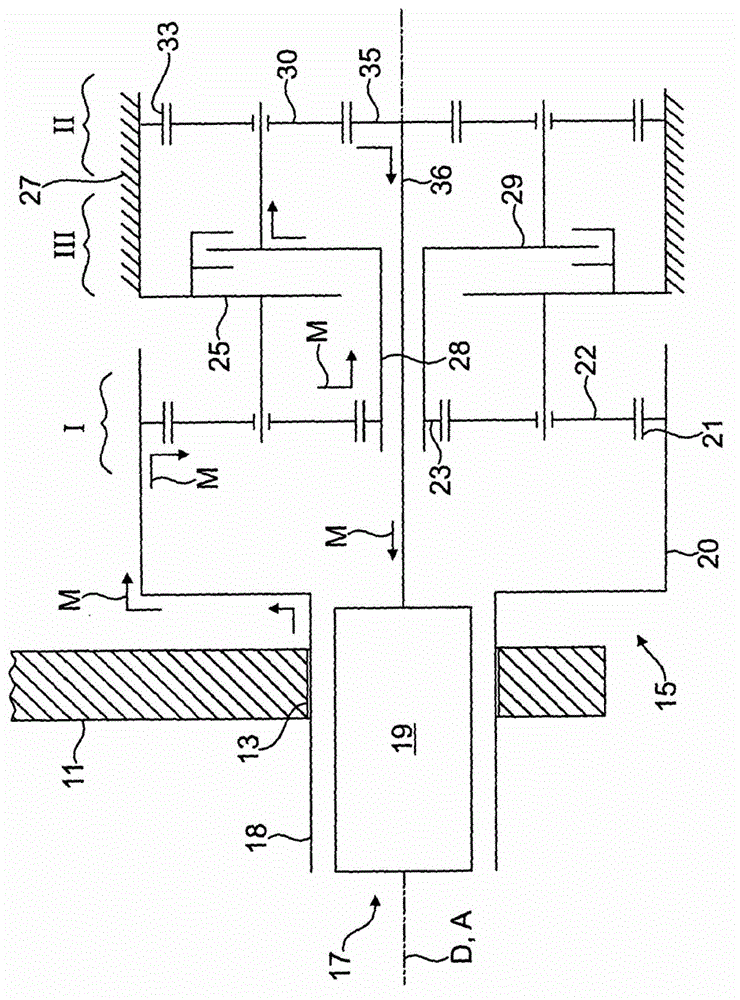

[0026] according to image 3 , the electric shock absorber 15 has a rotating field generator 17 comprising a radially o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com