A rail vehicle elastic wheel with active control of vibration and noise reduction

A technology for vibration and noise reduction and rail vehicles, which is applied in the field of rail vehicles, can solve the problems that there is no improvement, and the elastic wheels do not take into account the amplitude and frequency of the impact and vibration of the wheel and rail. The effect of increasing the damping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

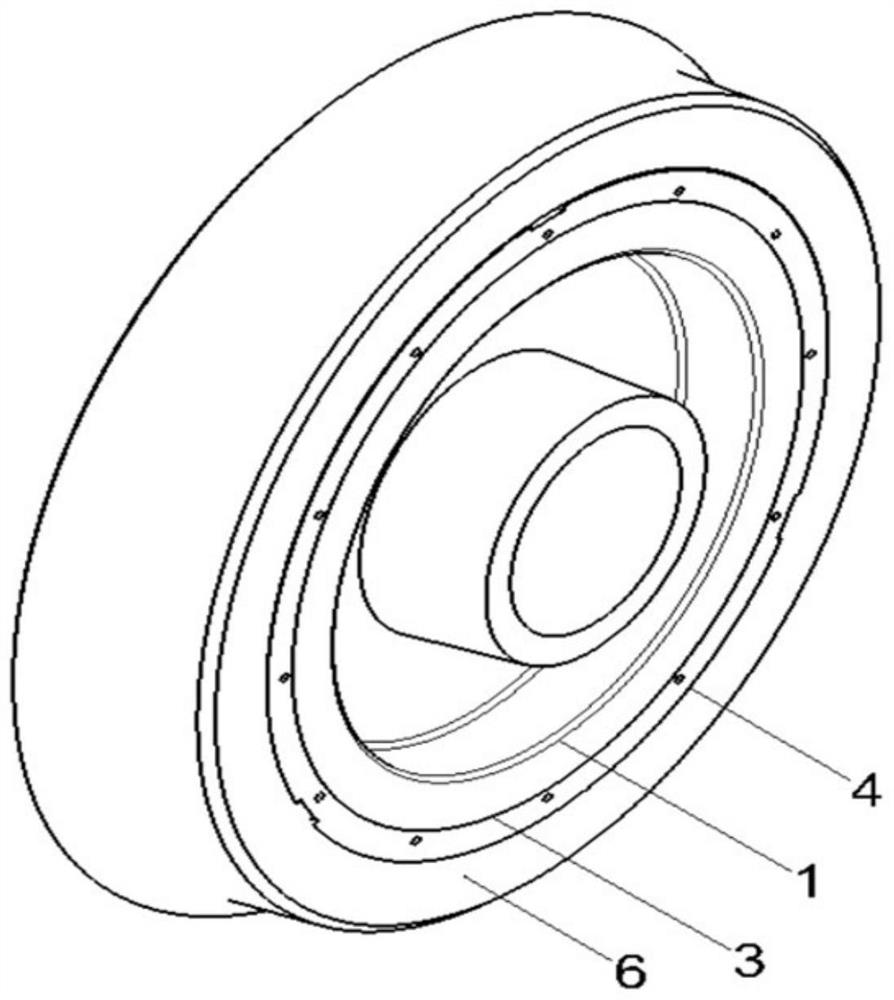

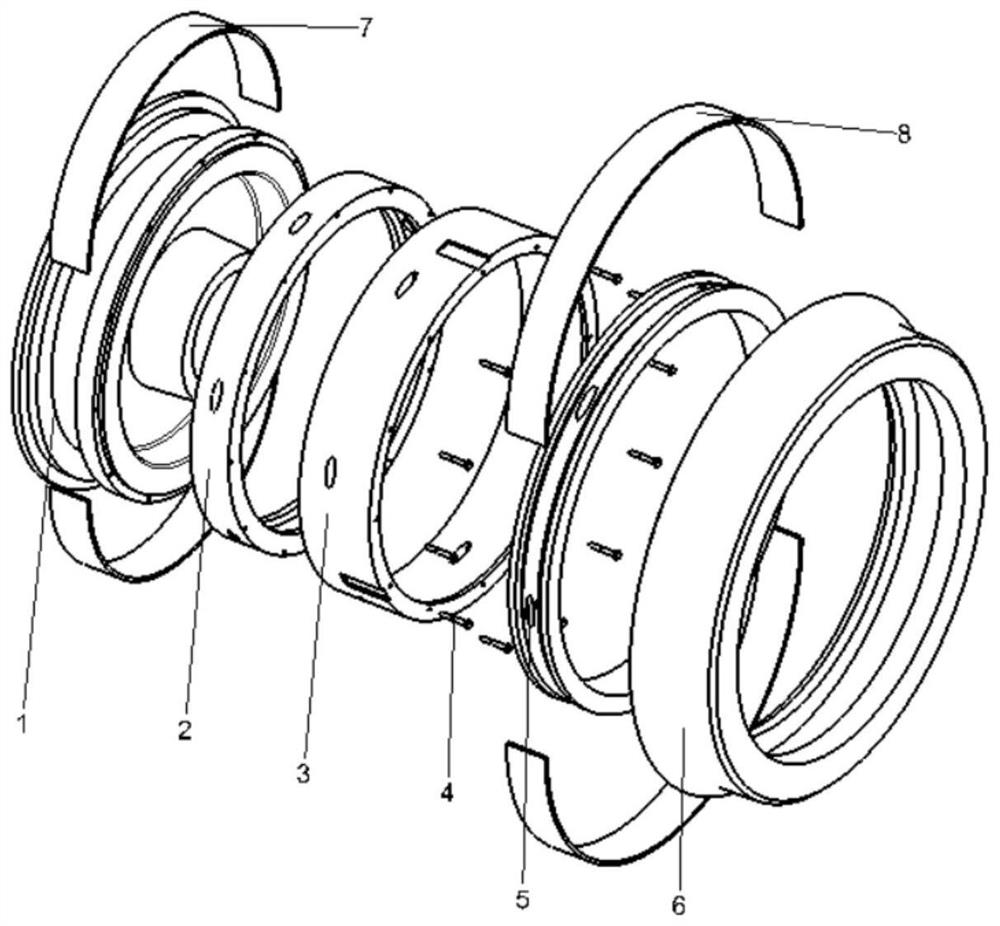

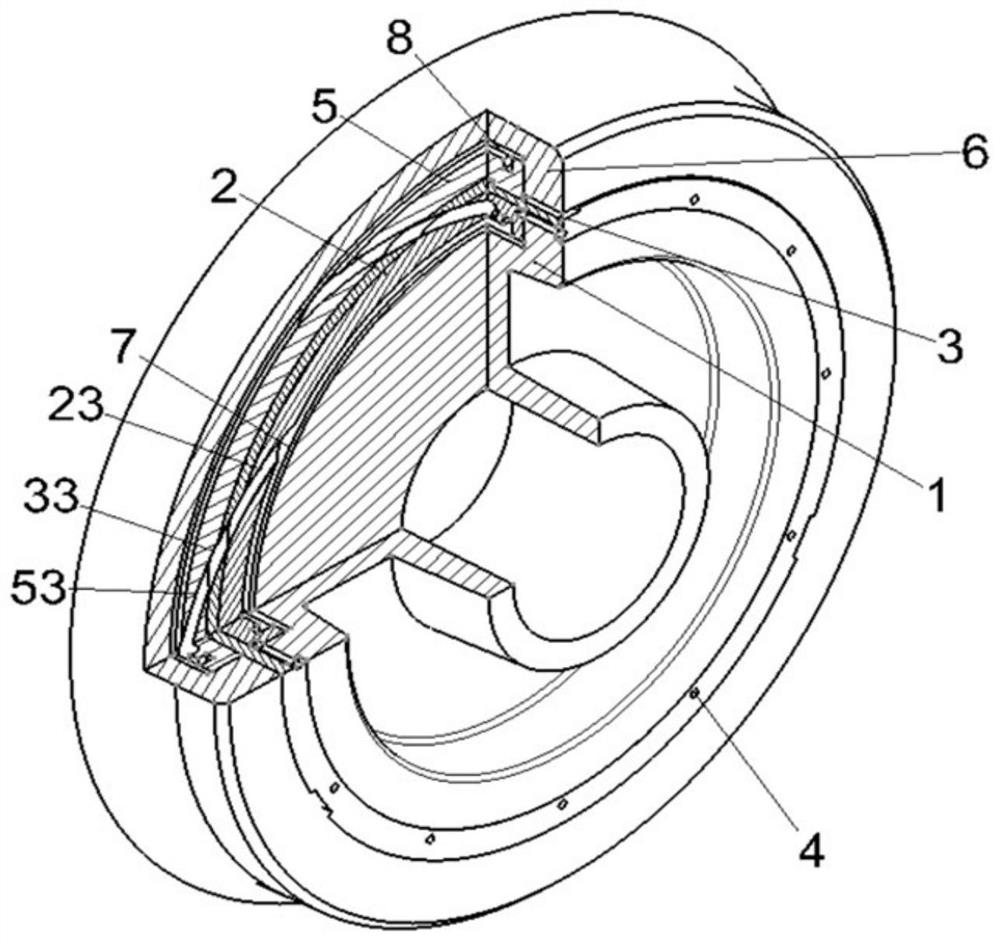

[0040] see figure 1 with figure 2 A rail vehicle elastic wheel for actively controlling vibration and noise reduction includes a wheel core 1, a tire 6 and an elastic mechanism, the elastic mechanism is located between the wheel core 1 and the tire 6; a pair of On the upper sealing tile 8, a pair of lower sealing tiles 7 are installed between the elastic mechanism and the wheel core 1.

[0041] see image 3 , Figure 4 with Figure 5 , The elastic mechanism includes an upper rubber ring 5, a pressure ring 3 and a lower rubber ring 2, the upper rubber ring 5 is set on the outer circumference of the pressure ring 3, and the lower rubber ring 2 is embedded on the inner circumference of the pressure ring 3. see Figure 9 with Figure 10 , the circumference of the upper rubber ring 5 is evenly distributed with six radial upper holes 53; see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com