High-performance railway wagon swing bolster structure and bogie

A high-performance technology for railway wagons, applied in the direction of bogies, railway car body parts, devices for lateral relative movement between the underframe and the bogie, etc., can solve problems affecting the service life of bogie bolsters, and improve the use of Life, eliminate end point oscillation, solve the effect of sudden high amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

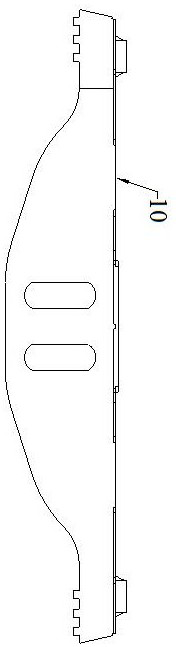

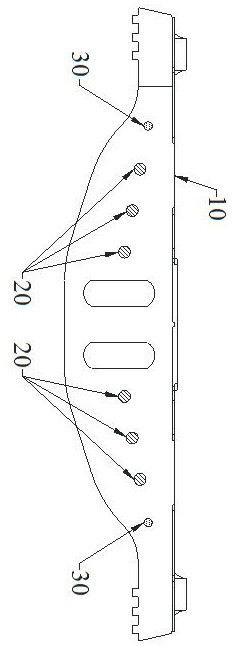

[0046] Such as Figure 3-8 As shown, the high-performance railway freight car bolster structure includes a bolster body 10, and the middle section of the bolster body 10 is provided with a plurality of first channels 11 arranged along the width direction of the bolster body 10, and the first The channel 11 is filled with a first vibration damping unit 20; the two ends of the bolster body 10 are respectively provided with a second channel 12 arranged along the width direction of the bolster body 10, and the second channel 12 is filled with a second Vibration damping unit 30.

[0047] Further, the first channel 11 includes a sinusoidal first through-hole section 111, and the two ends of the first through-hole section 111 are respectively provided with second through-hole sections 112 parallel to the width direction of the bolster body 10. , the first end of the second through hole section 112 communicates with the end of the first through hole section 111 , and the tail end of ...

Embodiment 2

[0052] Based on Embodiment 1, the first non-Newtonian fluid-filled region 21 and the second non-Newtonian fluid-filled region 31 are filled with non-Newtonian fluid fillers, and the preparation method of the non-Newtonian fluid fillers is as follows:

[0053] Mix and react 4,4'-diaminodiphenyl ether, dimethylacetamide and pyromellitic dianhydride at a mass ratio of 1:(1.5-2):(7-9) to prepare a polyamic acid solution , mix and stir the polyamic acid solution, methyl silicone oil and azobisisobutyronitrile according to the mass ratio of 100:(15-22):(2.1-2.3) and react at a temperature of 79-88°C for 2-3h, Nitrogen gas was introduced during the reaction process; after that, the temperature was raised to 105-110°C and the reaction was stirred for 30 minutes, and a new product was obtained after cooling to room temperature. The non-Newtonian fluid filler was obtained after the new product was placed at room temperature for 10 days.

[0054] Preferably, 4,4'-diaminodiphenyl ether, d...

Embodiment 3

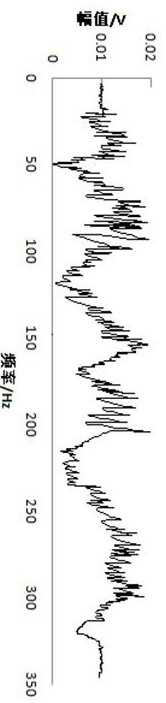

[0061] Bolster Vibration Test Experiment

[0062] The speed of the railway freight car is 100km / h, the vibration signal is collected by the acceleration sensor installed at the bolster in the bogie, and the sampling frequency is 10kHz; the original vibration signal is decomposed by the EEMD method to obtain the IMF component, and the effective IMF component is selected for The signal is reconstructed to obtain the corresponding vibration signal spectrum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com