Refrigerating machine oil and working fluid composition for refrigerating machines

一种冷冻机油、组合物的技术,应用在润滑组合物、石油工业、化学仪器和方法等方向,能够解决冷冻机油易滞留、不良、无法获得制冷剂与冷冻机油相容性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~36 and comparative example 1~15

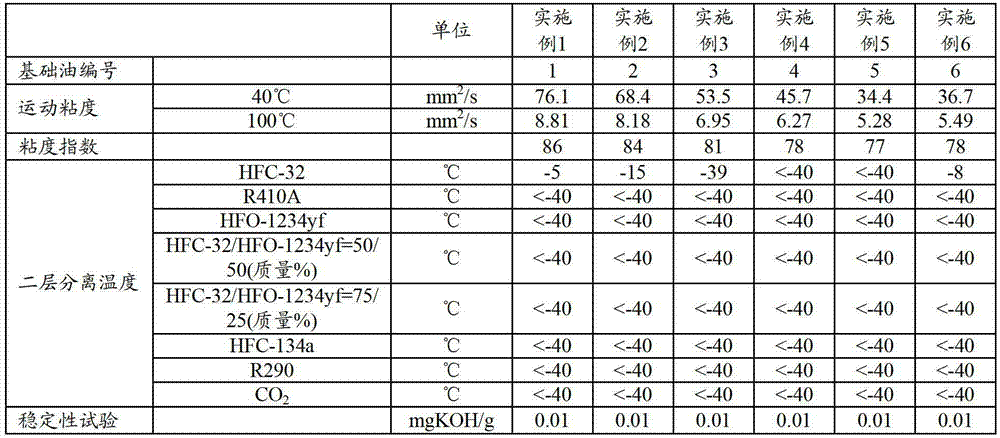

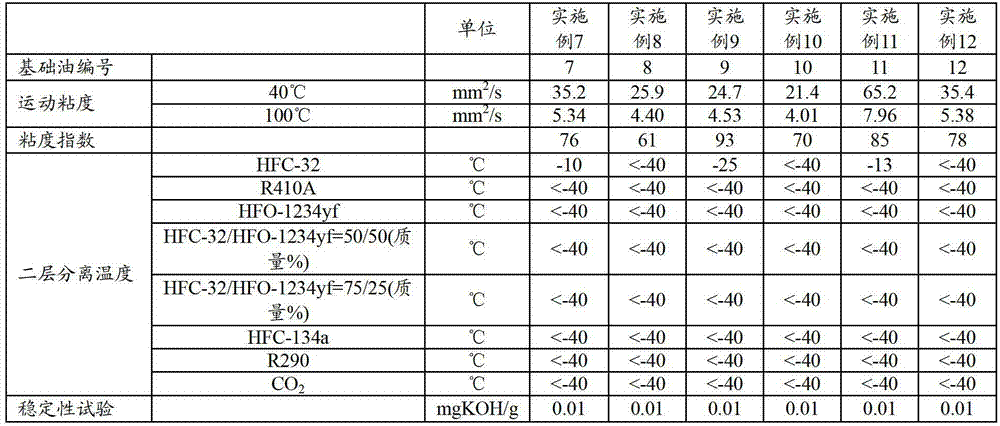

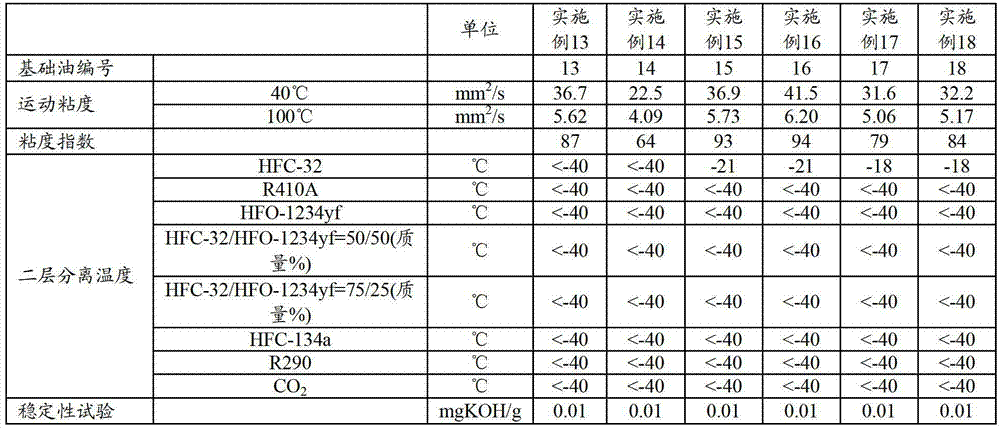

[0113] In Examples 1 to 36 and Comparative Examples 1 to 15, base oils 1 to 36 shown below and additives 1 to 5 were blended so as to form the composition ratios shown in Tables 1 to 10, respectively, to prepare sample oils . The properties of each sample oil obtained are shown in Tables 1-10.

[0114] (base oil)

[0115] Base oil 1: Tetraester of pentaerythritol and fatty acid mixture (mixture of 30 mol% 2-methylpropionic acid and 70 mol% 3,5,5-trimethylhexanoic acid)

[0116] Base oil 2: Tetraester of pentaerythritol and fatty acid mixture (mixture of 35 mol% 2-methylpropionic acid and 65 mol% 3,5,5-trimethylhexanoic acid)

[0117] Base oil 3: Tetraester of pentaerythritol and fatty acid mixture (2-methylpropionic acid 50 mol%, 3,5,5-trimethylhexanoic acid 50 mol% mixture)

[0118] Base oil 4: Tetraester of pentaerythritol and fatty acid mixture (mixture of 60 mol% 2-methylpropionic acid and 40 mol% 3,5,5-trimethylhexanoic acid)

[0119] Base oil 5: Tetraester of pentaer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com