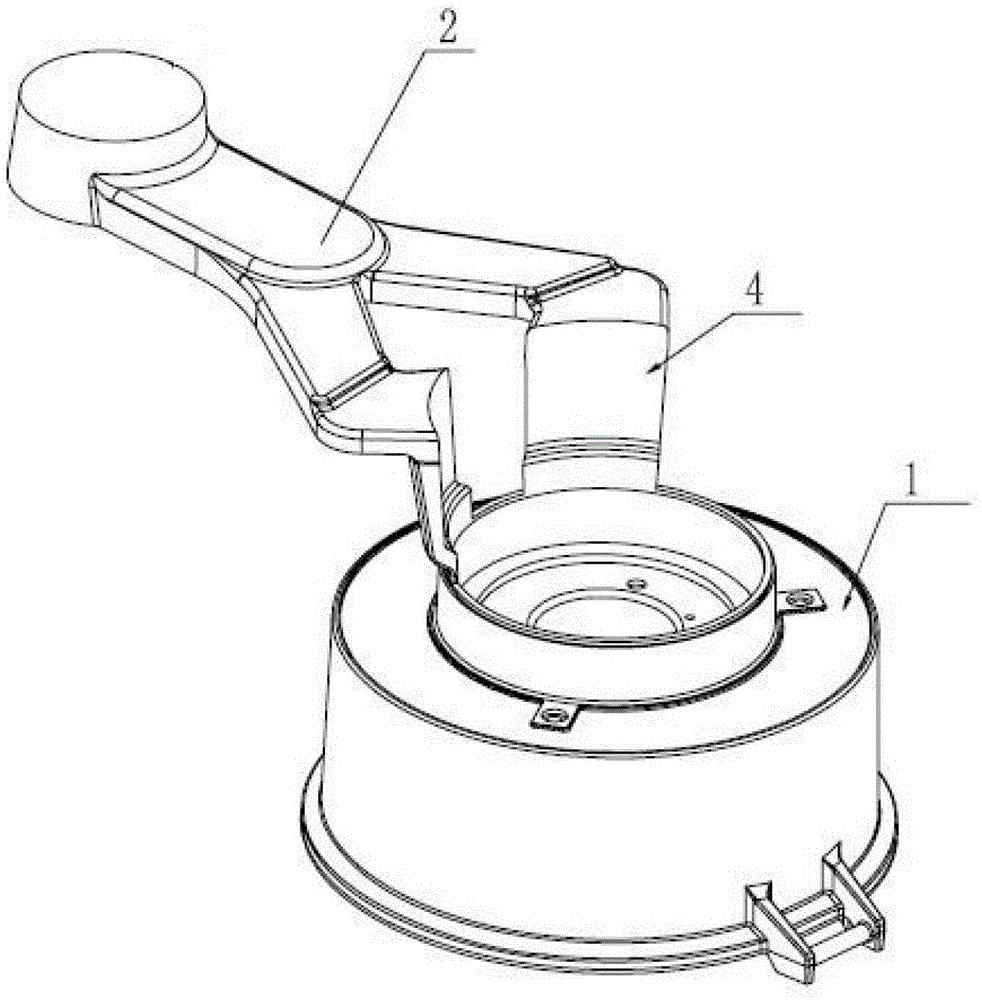

A mold structure in which the core of the lampshade is released first and the top is fed

A core and demolding technology, applied in the field of die-casting molds, can solve the problems of affecting product quality, excessive tightening force of large-sized cores in fixed molds, easy to be trapped in air, etc., so as to solve the problem of poor molding and avoid strain or cracking. , The effect of improving the yield of die casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

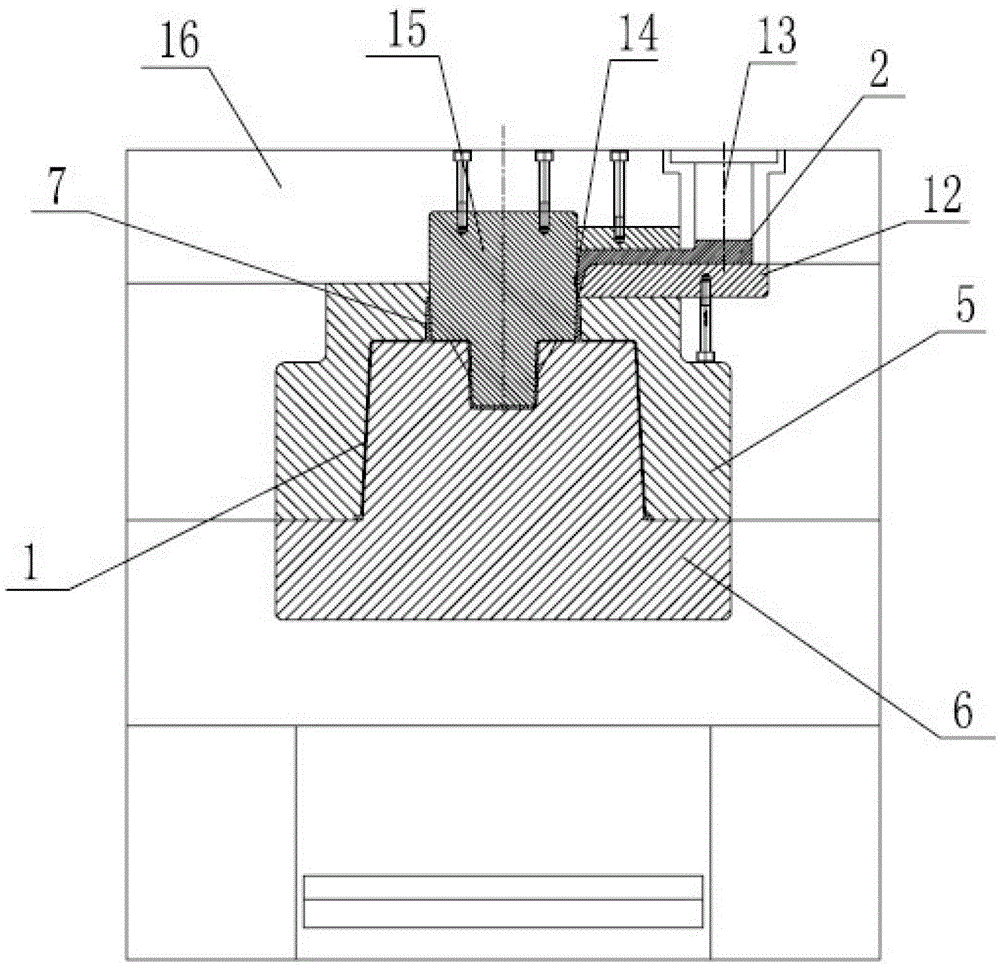

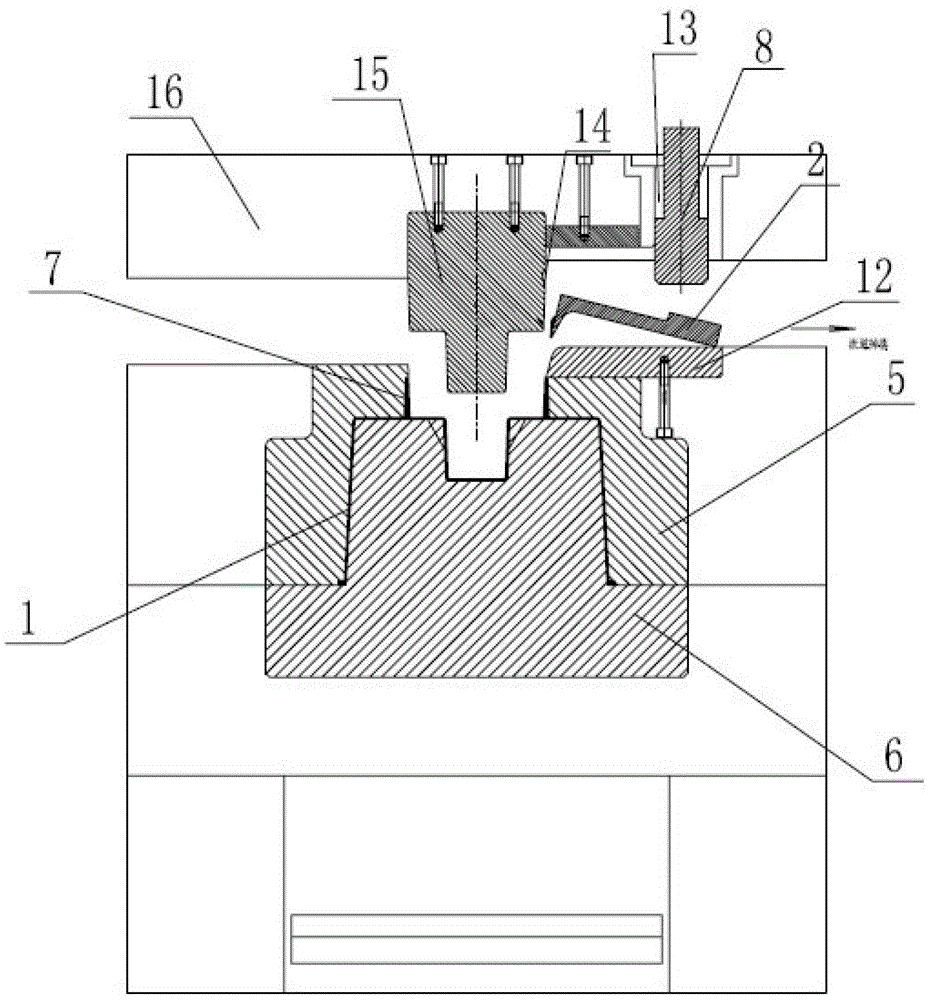

Embodiment 1

[0017] After the undetermined mold 5, the movable mold 6 and the large core 15 are arranged, the material is fed through the feed port 13, and the molten aluminum enters the mold cavity 1 after passing through the main channel 2 and the runner 4, and fills the entire mold cavity 1 from top to bottom , after the casting is formed, the upper platen 16 moves upwards to drive the large core 15 to move upwards, the undercut break groove 14 breaks the runner, and the tracking punch 8 pushes the main runner 2 out of the feed port 13, and the runner goes from The side of the mold falls, while the fixed mold 5 still presses the casting, then the fixed mold 5 and the movable mold 6 are opened along the parting surface, the casting remains on the movable mold 6, and the casting is ejected smoothly by the ejector pin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com