Heating time automatic auxiliary type self-temperature-control and self-adaption wire feed flame brazing device

A heating time, flame brazing technology, applied in welding equipment, metal processing equipment, auxiliary devices, etc., can solve the problems of scrapped workpiece, melting point restricting the application of brass welding wire, copper tube overburning, etc., to achieve high production efficiency, welding Precise temperature control and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

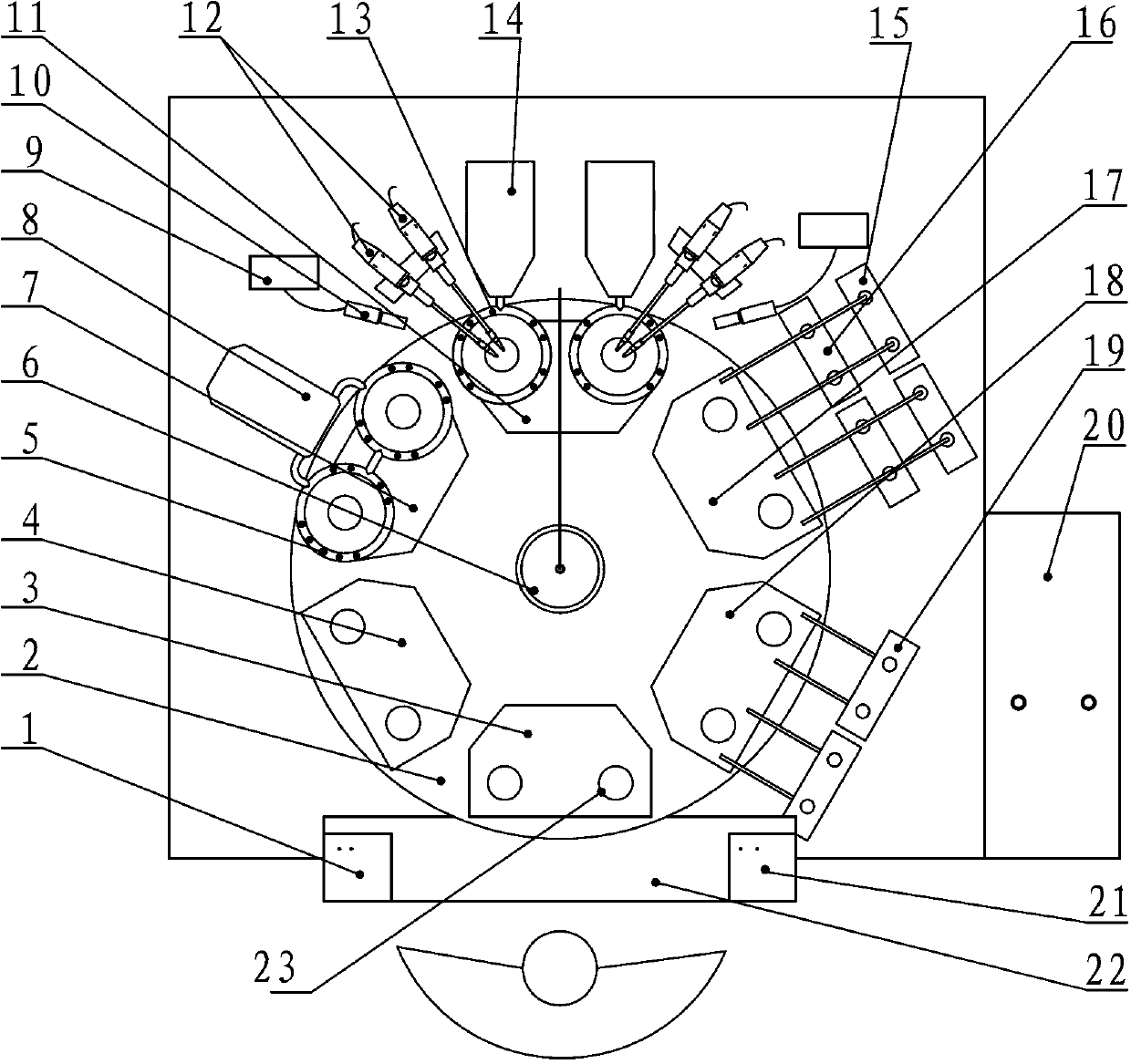

[0021] Such as figure 1 As shown, the present invention mainly includes a turntable part, a flame welding part and a control part.

[0022] Among them, the turntable part includes a turntable 2, a turntable indexing mechanism 6, a loading and unloading station 3, a workpiece detection station 4, a preheating station 7, a heating and welding station 11, a water cooling and air cooling station 17, and an air cooling station. Station 18. A turntable indexing mechanism 6 is arranged in the middle of the turntable 2, and the turntable can be rotated according to an angle through the turntable indexing mechanism 6, and the intermittent motion of turning and stopping is repeated. The six stations are equiangularly distributed on the turntable 2 according to the circumferential order, and each station is equipped with two sets of fixtures 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com