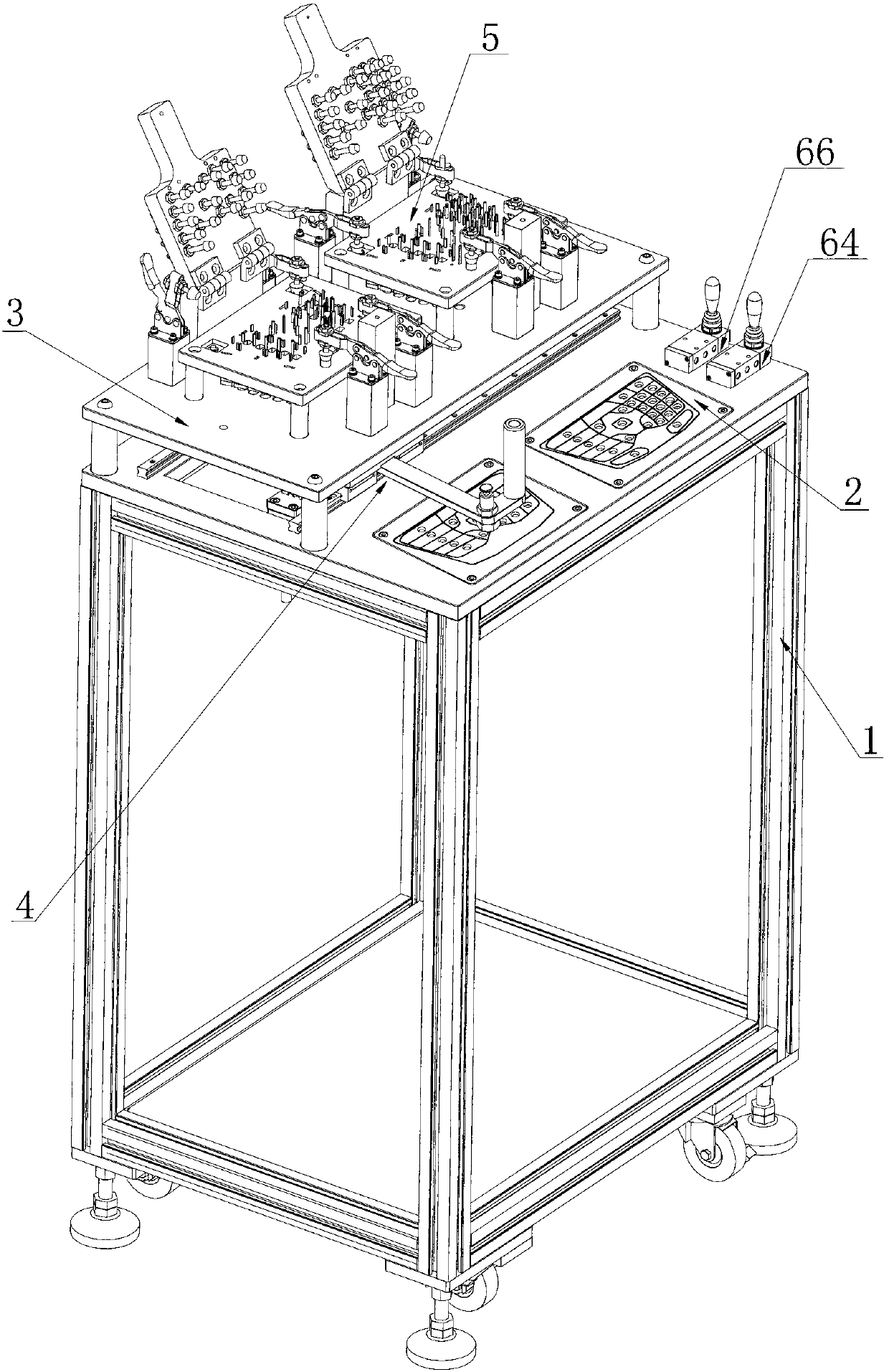

Key disassembly tool for radio panel

A technology for dismantling tooling and radios, applied in the field of machinery, can solve problems such as easy scratches on hands, time required for about ten minutes, work-related accidents, etc., and achieve the effect of improving production efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

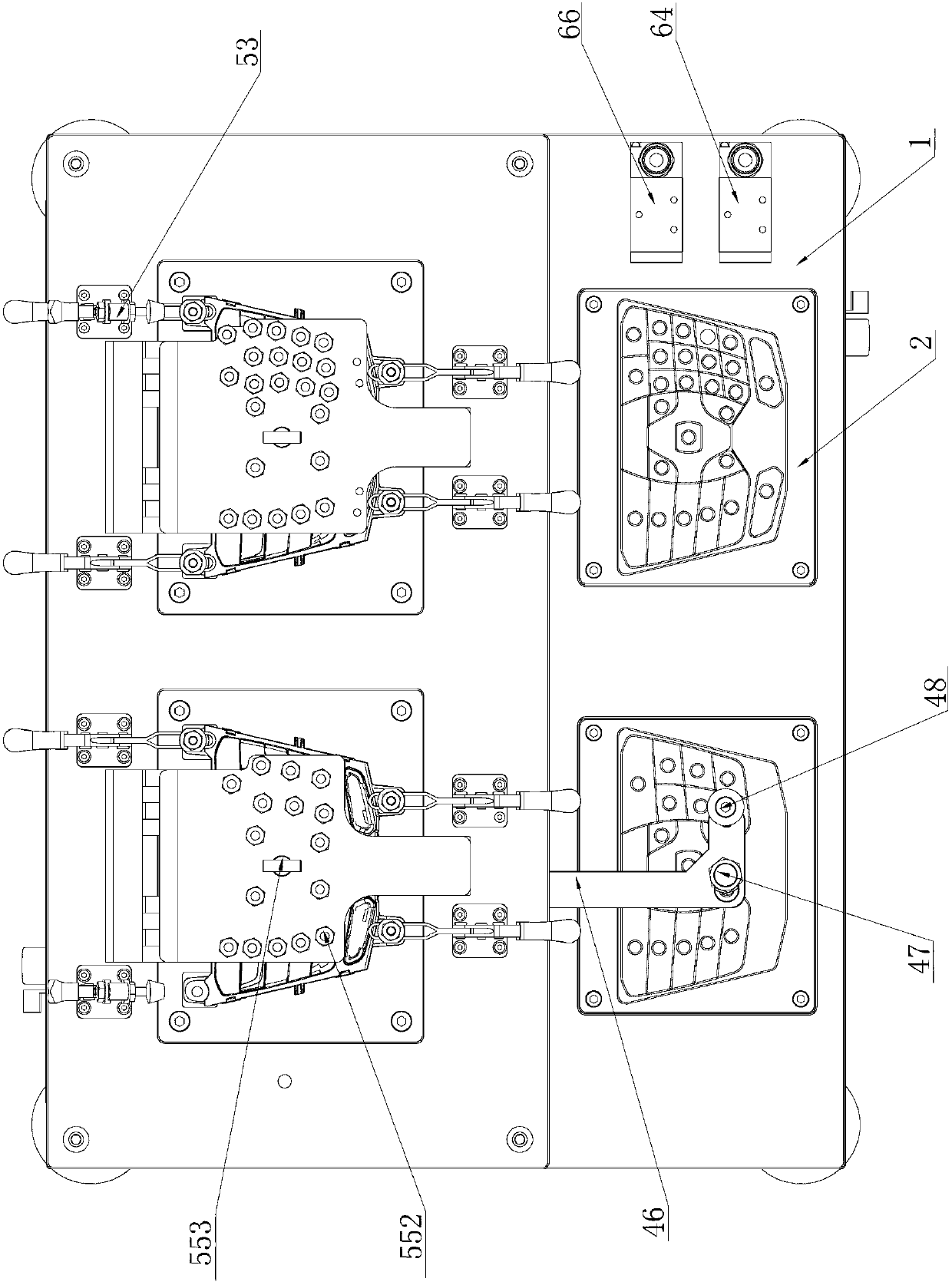

Embodiment 1

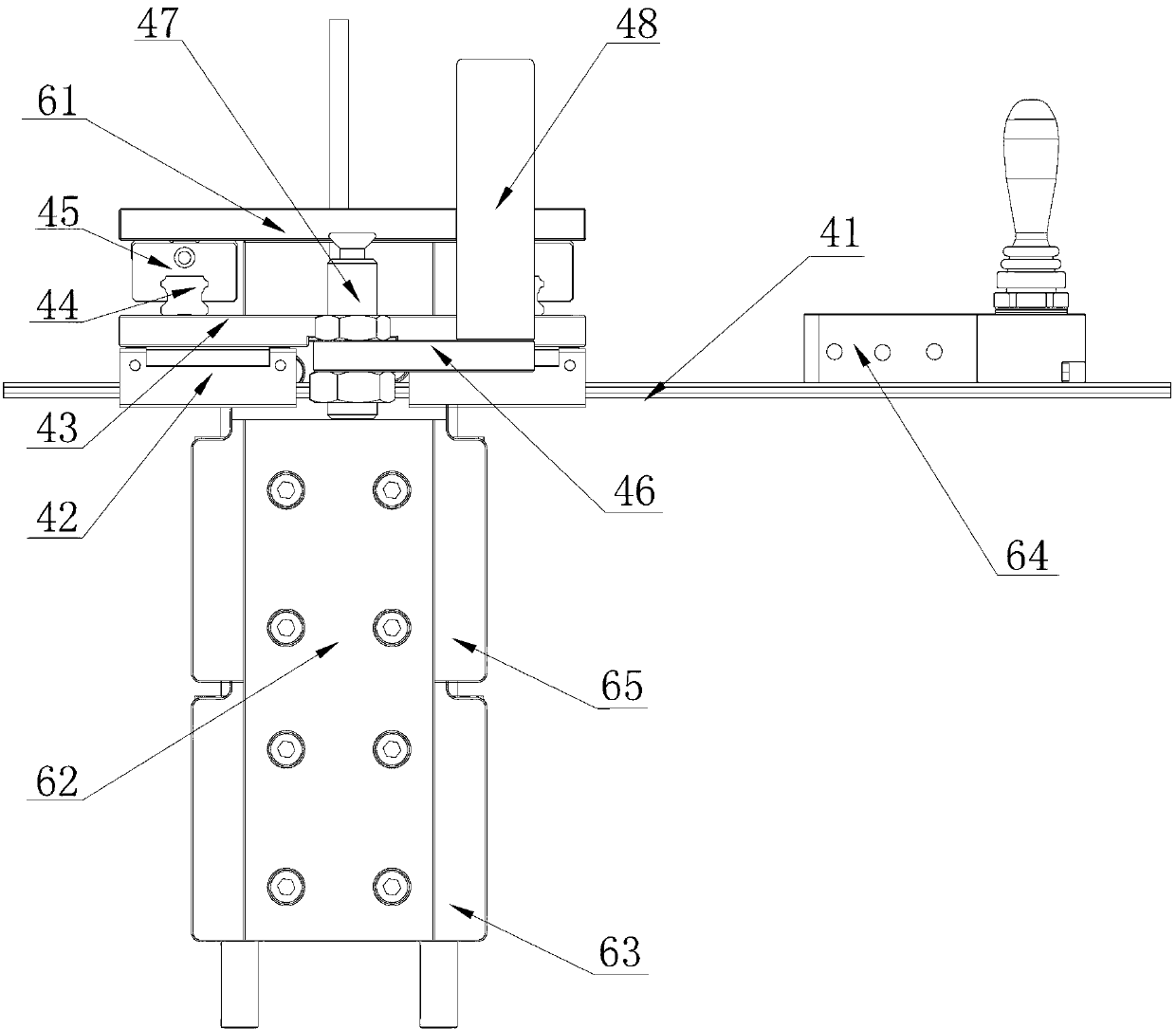

[0037] The concrete operating method of the present invention is as follows: 1, the key panel to be removed is placed on the frock, and the pressure head of the clamp 53 is pressed down, so that the pressure head of the clamp 53 is closely attached to the positioning pin 513, and the radio panel to be removed is fixed 7; 2. Press down the pressing plate 55 so that the positioning pin 551 of the pressing plate 55 is embedded in the pin positioning hole 561 on the positioning column 56 of the pressing plate, the purpose of which is to facilitate the expansion of the key buckle (when removing the OK key, first use the rotating handle 553 rotate the pressure head above the OK key to the working position); 3, operate the movable handle 48, locate in the button simulation mold 2, and move the plunger 47 to the position of the button 71 to be disassembled in the button simulation mold 2 Above, make the cylinder rod of the ejecting cylinder 65 reach the bottom of the button 7 to be dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com