Die cutting device of plastic bag notching machine

A plastic bag and punching technology, applied in the field of plastic bag processing equipment, can solve the problems of unstable work, inconvenient, inaccurate adjustment, etc., and achieve the effect of strong practicability, simple structure, and quick and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

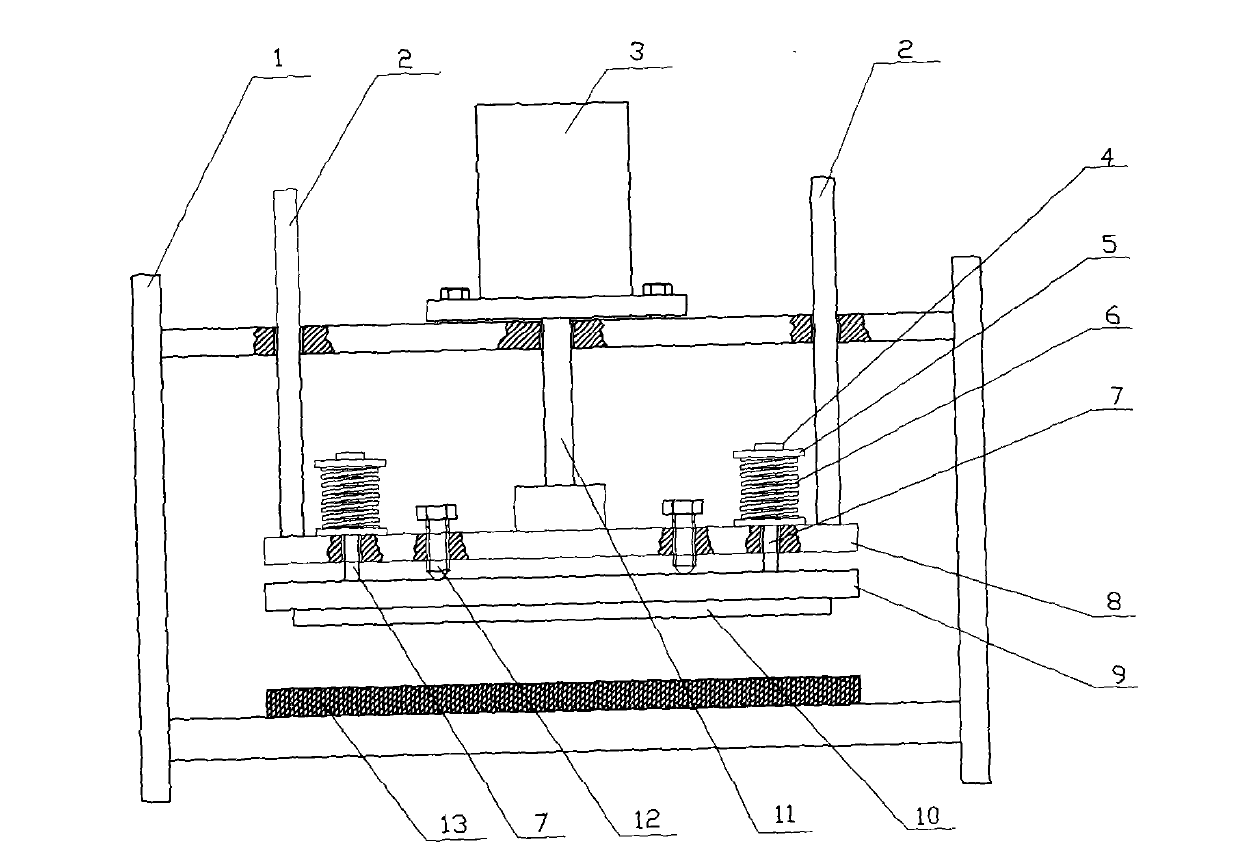

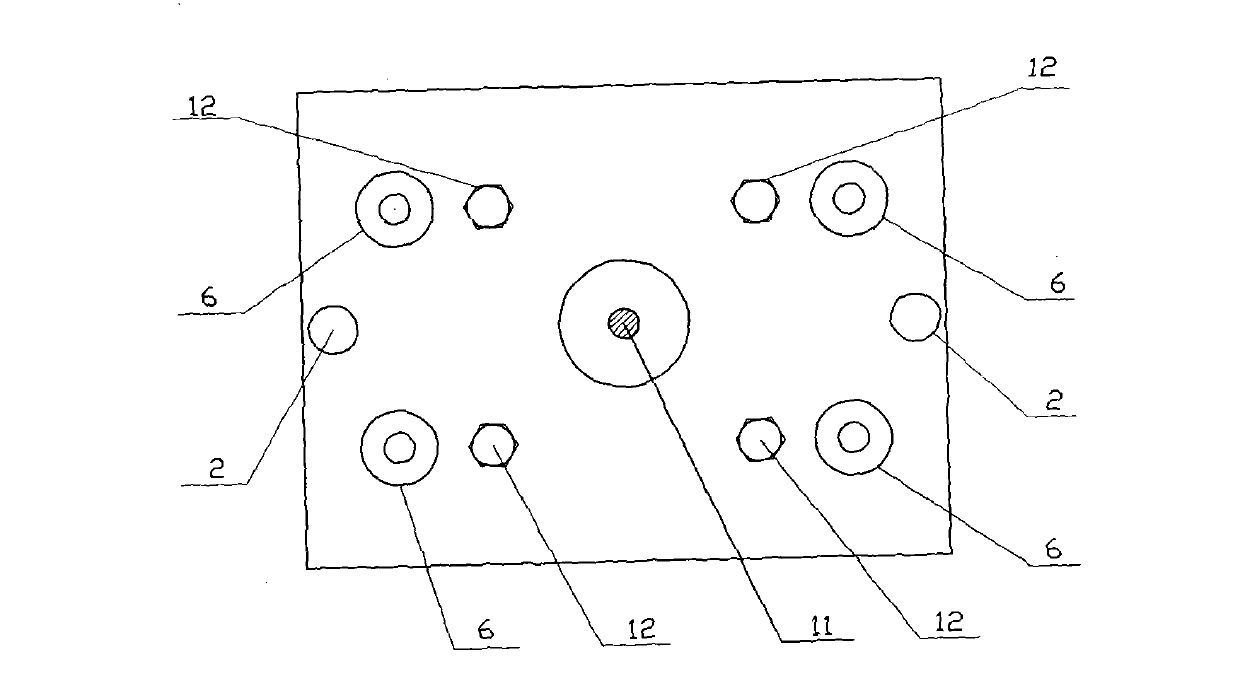

[0010] Attached below figure 1 , attached figure 2 The present invention is further described. The punching device of the plastic bag punching machine described in the present embodiment comprises frame 1, and cylinder 3 is installed in the middle position of the upper end of described frame, and adjusting plate 8 is installed in the lower end of cylinder rod 11, in order to limit adjusting plate 8 and The punching knife 10 rotates with the cylinder rod 11, the guide rods 2 are respectively installed on the left and right sides of the adjustment plate 8, through holes are respectively drilled on the four corners of the adjustment plate 8, and four adjustment screws are installed inside the four through holes 12. Install slide rods 7 on the four corners of the punching knife seat plate respectively, and the four slide rods pass through the four through holes of the adjustment plate 8, and respectively install spring seats 5 and springs on the slide rods 7 of the passing parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com