Method for producing high-concentration lactic acid by lignocellulose at high temperature

A lignocellulose, high-concentration technology, which is applied in the field of efficient bioconversion of lignocellulose to produce high-concentration and high-optical purity lactic acid, can solve the problems of limiting the production rate and yield of lactic acid, low cellulose enzymatic hydrolysis efficiency, etc. The risk of bacterial contamination, the effect of improving the efficiency of enzymatic hydrolysis and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

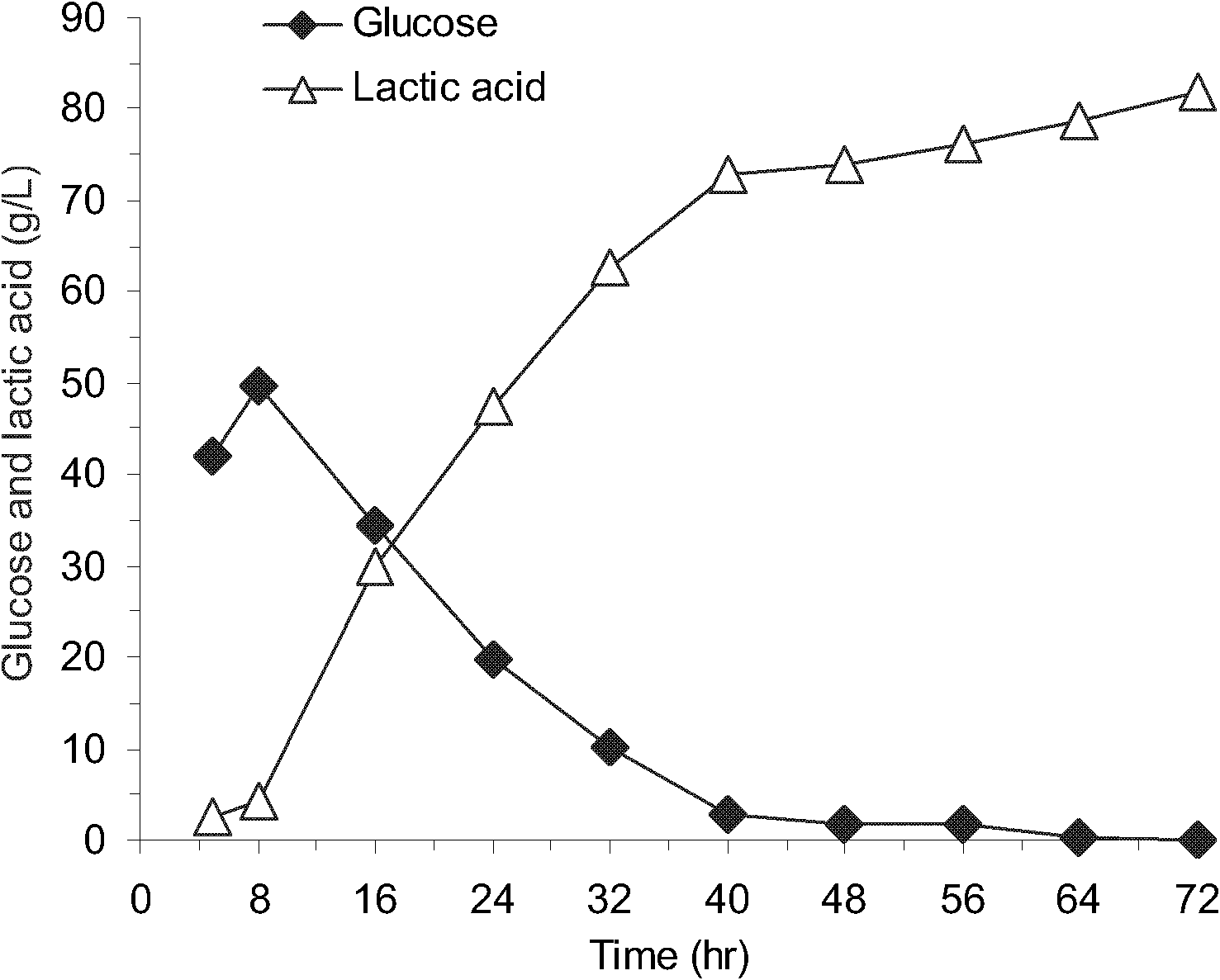

[0043] see attached figure 1 , the dried corn stalks were mixed with dilute sulfuric acid solution until the water content was 33% (w / w), the sulfuric acid concentration was 2.5% (w / w), and pretreated at 190°C for 3 minutes; the pH of the pretreated material was adjusted to 5.5, and the water content was 60 % (w / w), add Amorphotheca resinae ZN1, the strain used for biological detoxification, and culture in solid state at 25°C for 7 days; harvest the material, sterilize the material at 115°C for 20 minutes, add it to the fermenter after cooling, and adjust the solid in the fermenter The content is 25% (w / w), the dosage of cellulase is 15FPU / gDM, pre-saccharification at 50°C for 8h, the pH of the fermentation process is controlled by 5M sodium hydroxide at 5.5, fermentation is at 48°C for 72 hours, and the final lactic acid concentration is 81.80g / L .

Embodiment 2

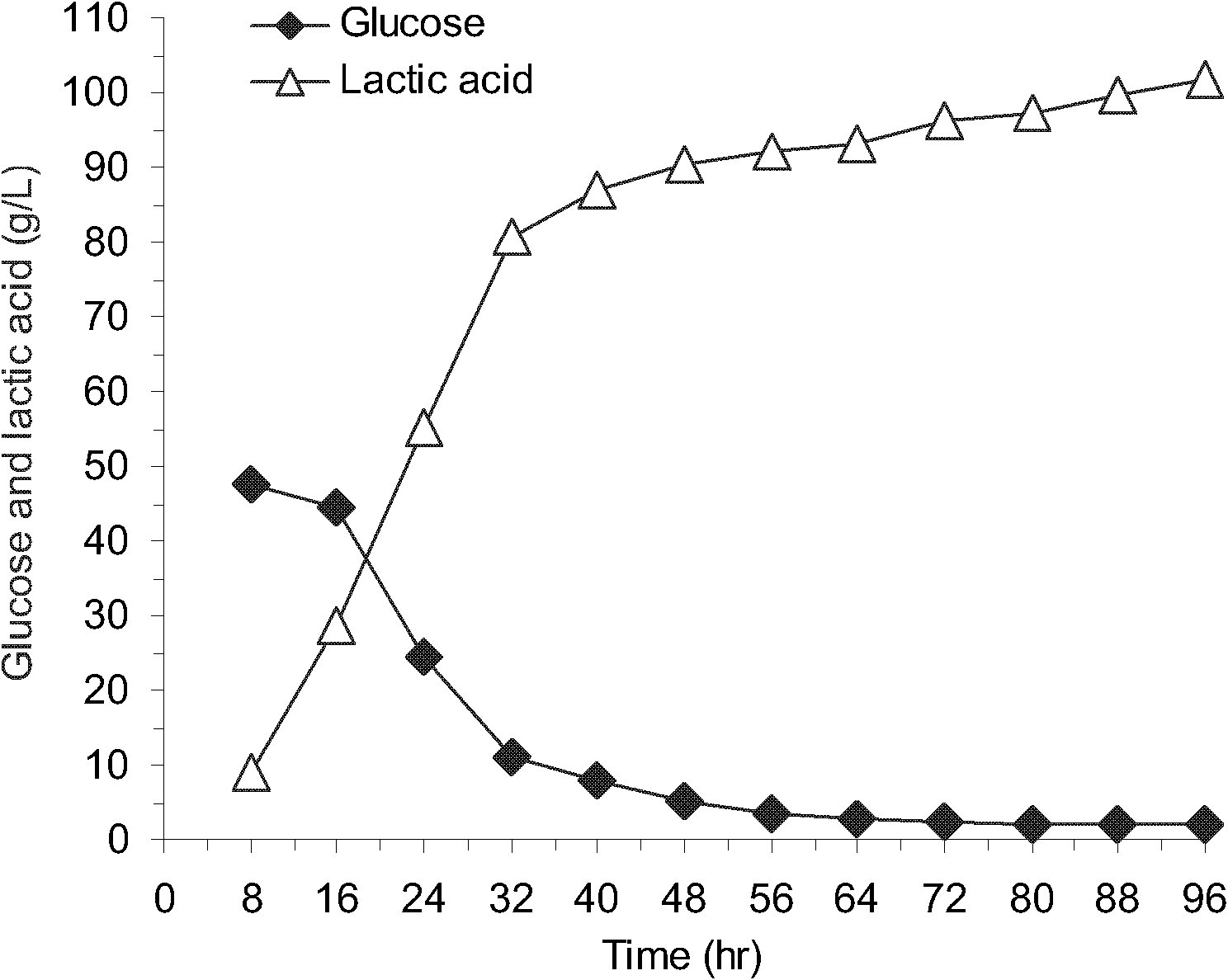

[0045] see attached figure 2 , the dried corn stalks were mixed with dilute sulfuric acid solution until the water content was 33% (w / w), the sulfuric acid concentration was 2.5% (w / w), pretreated at 190°C for 3 minutes, the pH of the pretreated material was adjusted to 5.5, and the water content was 60 %(w / w), add the strain Amorphotheca resinae ZN1 used for biological detoxification, and culture in solid state at 25°C for 7 days; harvest the material, sterilize the material at 115°C for 20 minutes, add it to the fermenter after cooling, and the solid content in the fermenter The mass fraction is 30%, the dosage of cellulase is 15FPU / gDM, pre-saccharification at 50°C for 8h, the pH of the fermentation process is controlled at 5.5 by 5M sodium hydroxide, fermentation is at 48°C for 72 hours, and the final lactic acid concentration is 101.60g / L.

[0046] The lignocellulose raw material involved in the present invention is not limited to corn stalks, and can also be one of whea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap