Detection and repair technique

A technology of oil well pump and process, which is applied in the field of oil well pump inspection and repair technology, can solve problems such as unable to meet the urgent needs of oil fields, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

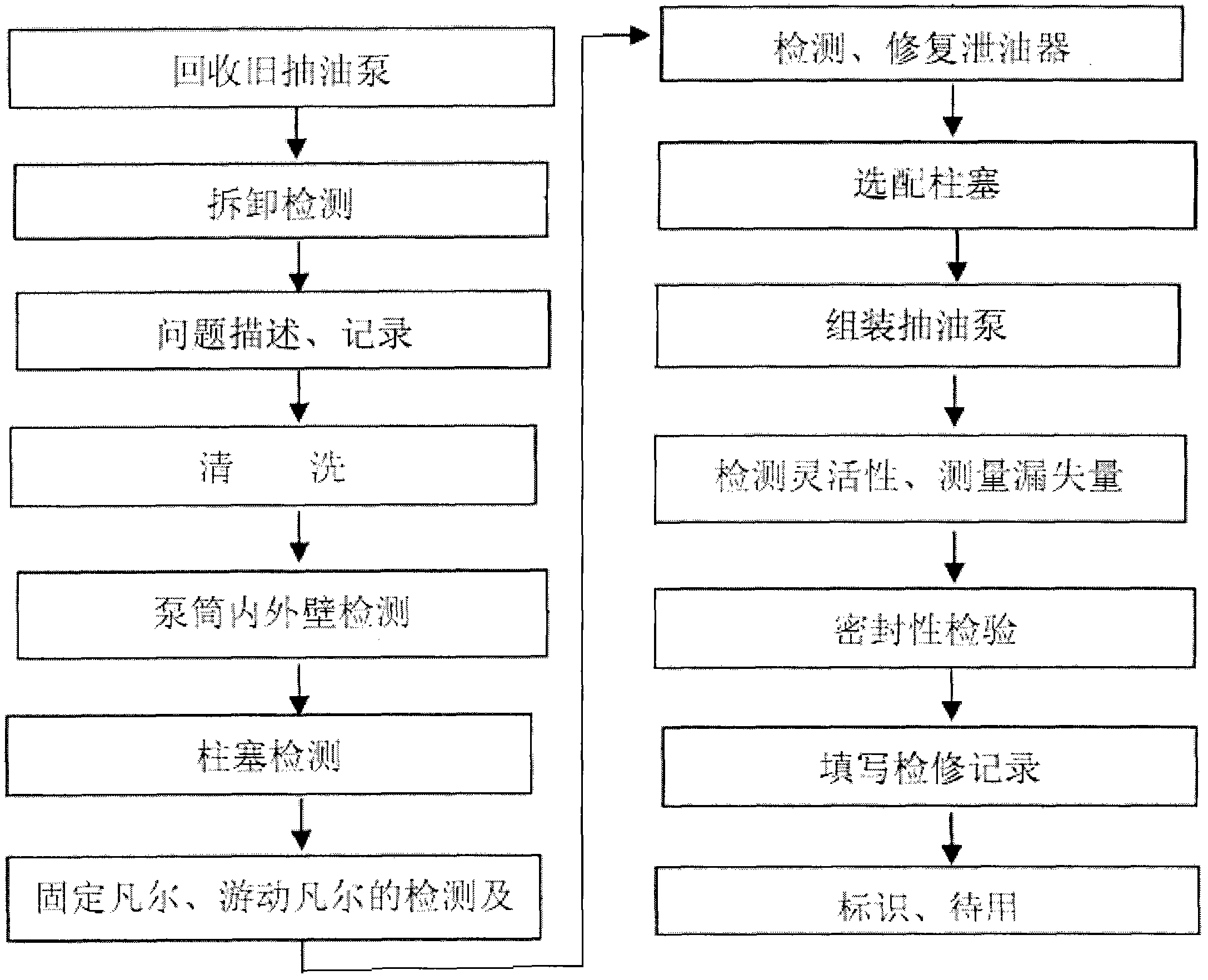

[0025] Such as figure 1 As shown, the oil well pump detection and repair process involved in this embodiment includes the following steps:

[0026] (a) recycling old oil well pumps;

[0027] (b) Disassemble and test the recovered old oil well pump;

[0028] (c) followed by cleaning;

[0029] (d) further testing after cleaning;

[0030] (e) Repair the oil drain;

[0031] (f) optional plunger;

[0032] (g) Assembling the well pump;

[0033] (h) detection flexibility, measurement leakage;

[0034] (i) tightness inspection;

[0035] (j) Fill in the maintenance records;

[0036] (k) Identification, ready for use.

[0037] In the step (b), the detected problems are described and recorded.

[0038] In the step (d), the detection includes: the detection of the inner and outer walls of the pump barrel, the detection of the plunger, the detection of the fixed Vers and the detection of the moving Vers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com