System and process for recovering heavy metals from plating bath aging solution

A technology for aging liquid and heavy metals, applied in refrigeration and liquefaction, refrigerators, zinc sulfate, etc., can solve the problems of high energy consumption in evaporation and concentration, low extraction efficiency, etc., and achieve energy saving in heating and cooling methods, reduced labor costs, and compact equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

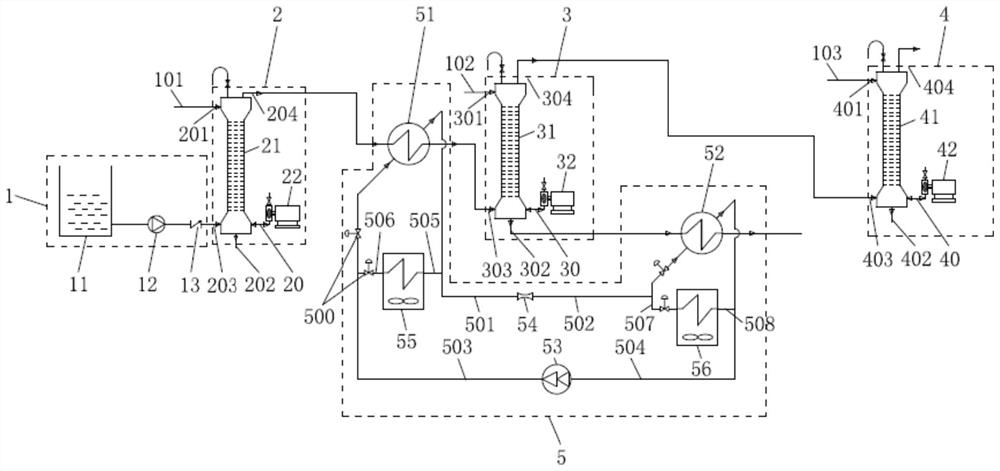

[0039] like figure 1 As shown, this embodiment discloses a system for recovering heavy metals from an aging solution of a plating tank, which includes an extractant addition unit 1 , an extraction unit 2 , a back-extraction unit 3 , a regeneration extractant unit 4 and a heat pump unit 5 . The extractant adding unit 1 includes a kerosene tank 11 , a kerosene pump 12 and a check valve 13 which are connected by pipelines in sequence. The heavy phase inlet 201 of the extraction unit 2 is connected to the plating tank aging solution discharge pipe 101 , and the light phase inlet 203 is connected to the extraction agent addition unit 1 . The heat pump unit 5 includes a heat exchange condenser 51 and a heat exchange evaporator 52 . The tube side fluid inlet of the heat exchange condenser 51 is connected with the light phase outlet 204 of the extraction unit 2 , and the tube side fluid outlet is connected with the light phase inlet 303 of the stripping unit 3 . The heavy-phase inle...

Embodiment 2

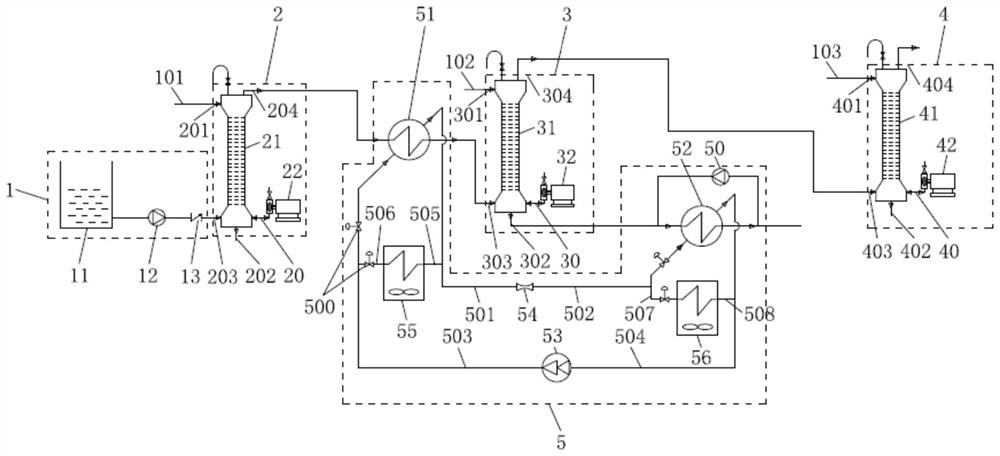

[0050] like figure 2 As shown, the only difference between this embodiment and the first embodiment is that a forced circulation pump 50 is connected in parallel between the tube-side fluid inlet and the tube-side fluid outlet of the heat exchange evaporator 52 . The function of the forced circulation pump 50 is to prevent the solution in the evaporative heat exchanger 52 from crystallizing due to a drop in temperature, resulting in poor heat exchange effect or even pipeline blockage. The rest of the structure and principle of this embodiment are the same as those of the first embodiment.

Embodiment 3

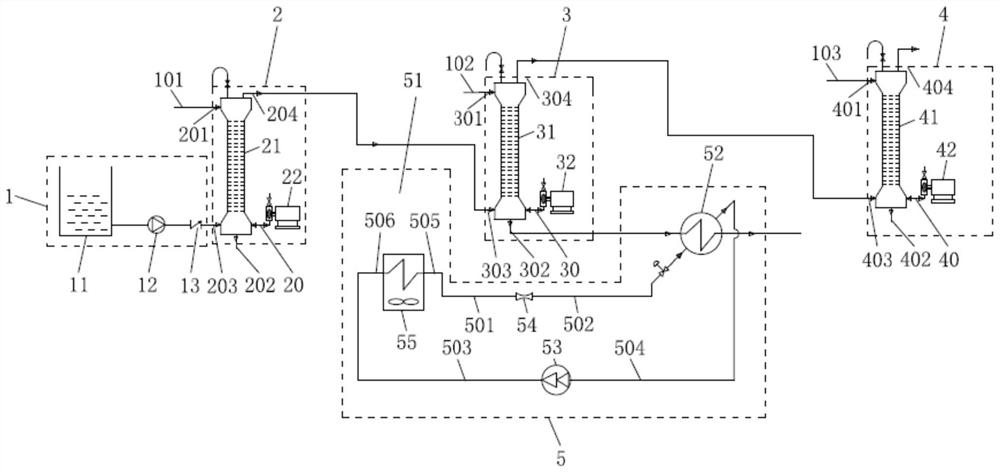

[0052] like image 3 As shown, the only difference between this embodiment and the first embodiment is that the heat pump unit 5 includes a heat exchange evaporator 52 , a refrigerant compressor 53 , a throttle valve 54 and an air-cooled condenser 57 . One end of the throttle valve 54 is connected to the air-cooled condenser 57 , and the other end is connected to the shell side fluid inlet of the heat exchange evaporator 52 . The refrigerant high-pressure outlet of the refrigerant compressor 53 is connected to the air-cooled condenser 57 , and the refrigerant low-pressure inlet is connected to the shell-side fluid outlet of the heat exchange evaporator 52 . The rest of the structure of this embodiment is the same as that of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com