Method for measuring thermal resistance of multi-layer heat-conducting material

A heat-conducting material and measurement method technology, applied in the field of testing, can solve the problems of not being able to find the problem quickly and conveniently, and not be able to analyze the thermal resistance composition of multi-layer heat-conducting materials, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

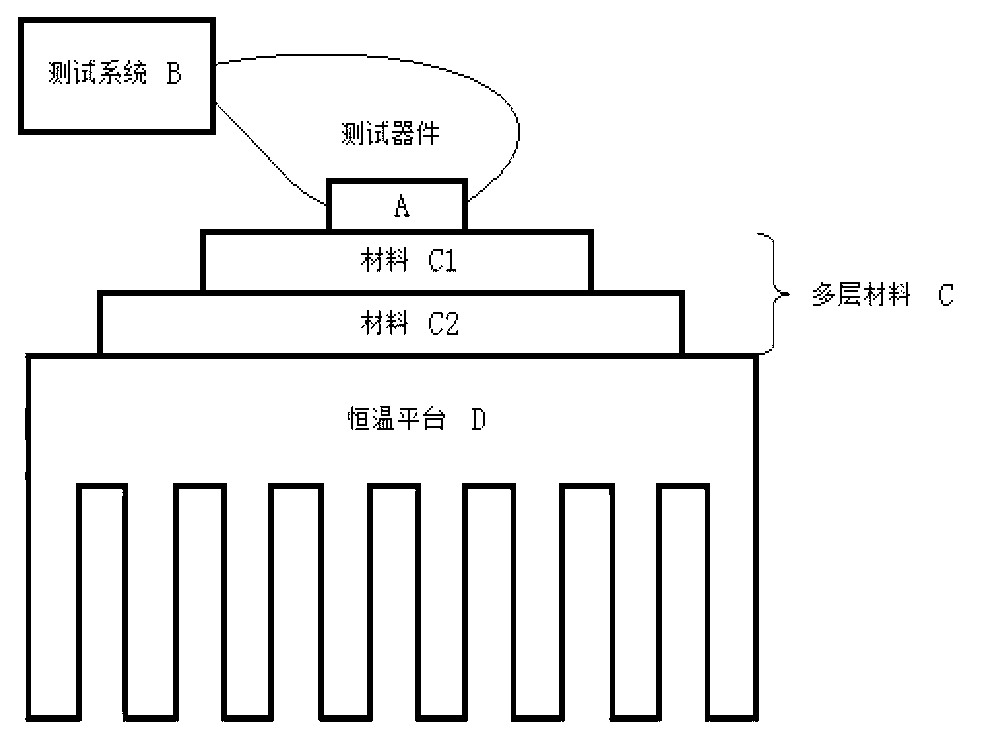

[0034] 1. The semiconductor device A is a power light-emitting diode; figure 1 As shown, from top to bottom, the semiconductor device A and the multi-layer heat-conducting material C are fixed on the constant temperature platform D in sequence;

[0035] Among them, the temperature coefficient of the PN junction and Schottky junction of the semiconductor device A is about -1~2mV / K, and the error of this value is not more than 7% between the absolute temperature of 275K and 475K;

[0036] The measurement system B includes: acquisition board B1, used to collect the voltage across the semiconductor device A; constant current source B2, used to provide the test current of the semiconductor device A; constant current source B3, used to provide the heating current of the semiconductor device A; computer B4 is used to control the opening of the acquisition board B1, and the constant current sources B2 and B3 provide heating current and test current on and off;

[0037] The multi-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com