Structure of thin-layer thermal resistance test probe and test method

A technology for testing probes and thermal resistance, applied in the direction of material thermal development, material thermal conductivity, etc., can solve problems such as inapplicable fine structure thermal reliability analysis, inability to extract temperature information, incomplete thermal resistance structure, etc., reaching the scope of application wide, improve sensitivity and signal-to-noise ratio, and smooth the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

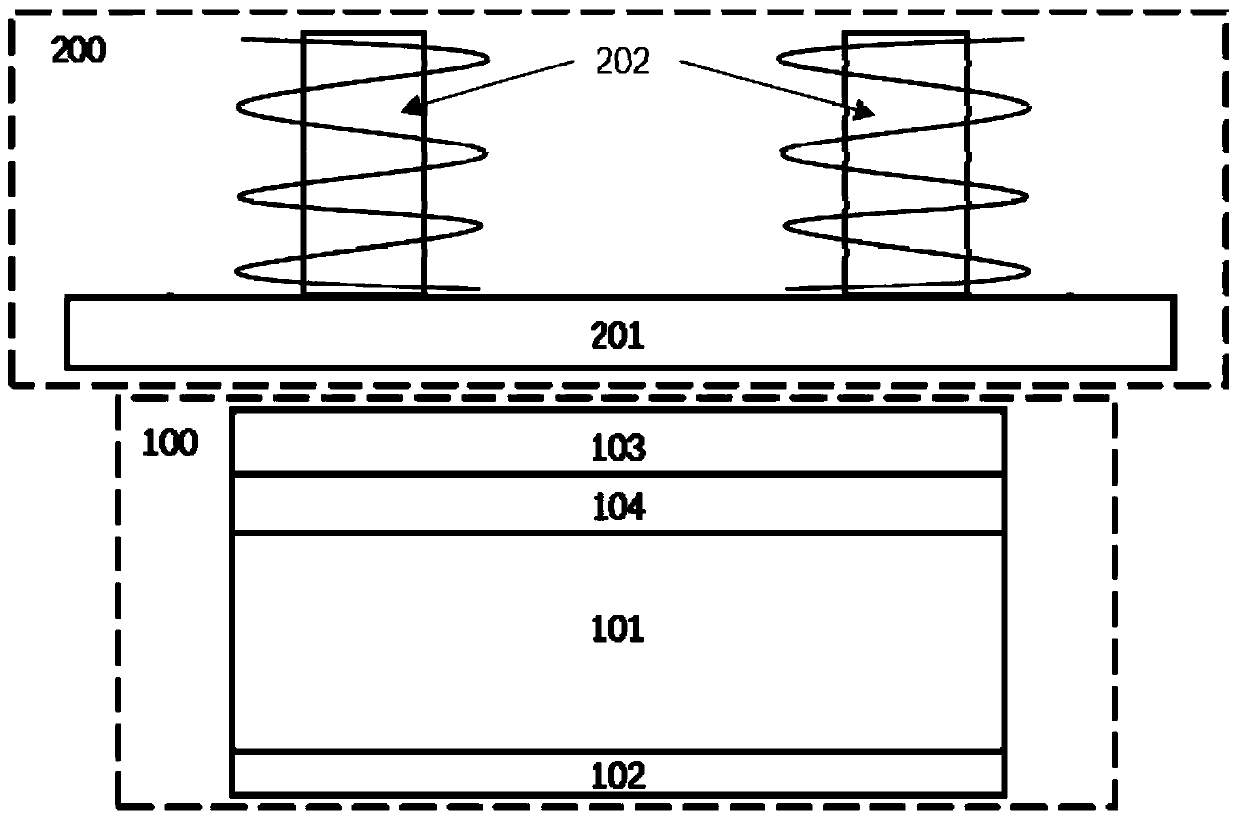

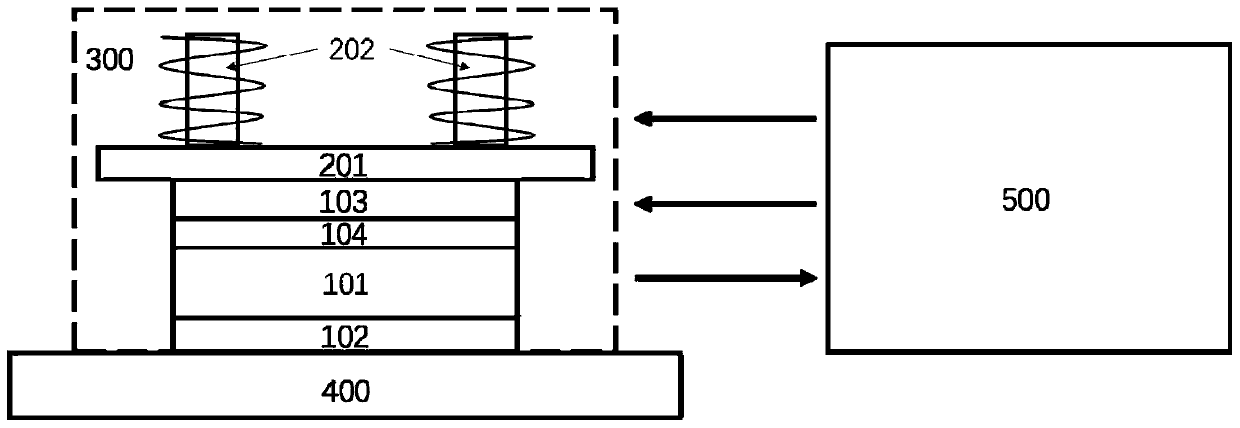

[0021] like figure 1 A schematic diagram of the structure of a thin-layer thermal resistance test probe is shown, including, 100: probe chip; 101: substrate structure; 102: measurement source; 103: heating source; 104: heat spreading layer; 200: packaging structure; 201 : substrate; 202: spring support structure;

[0022] The probe chip 100 is made of a measurement source 102, a heating source 103 and a heat soaking layer 104 on a semiconductor substrate material 101 through semiconductor processes such as photolithography, ion implantation and photolithography;

[0023] The measurement source 102 consists of multiple diodes connected in series and in parallel to form a temperature probe, with a total chip area of about 1.5mm×1.5mm. The change of the forward junction voltage drop of each diode with temperature is about 2mV / °C. When 10 diodes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com