Loaded H-plane equiphase power divider

A technology of equal phase and power divider, which is applied in the direction of waveguide devices, electrical components, connecting devices, etc., can solve the problems of increased volume at intersections, high broadband series, and reduced processing accuracy, and achieves increased working bandwidth and broadband The effect of high levels and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

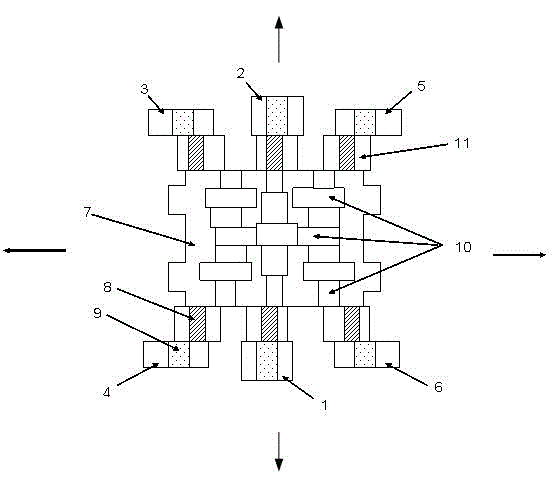

[0026] Such as figure 1 As shown, the loaded type H-plane equal-phase power divider includes a coupling cavity 7, an input and output terminal connected to the coupling cavity 7, that is, an input port 1 connected to the coupling cavity 7, an output port A3, an output port B5, and an isolation port A2, isolated port B4, isolated port C6. The input port 1, the isolation port B4, and the isolation port C6 are located at the front end of the coupling cavity 7, and the isolation port A2 is located at the rear end of the coupling cavity 7. The front end and the rear end are two opposite sides of the coupling cavity 7, and the isolation ports B4 and The isolation port C6 is located on both sides of the input port 1, the output port A3 and the output port B5 are respectively located on both sides of the isolation port A2; the coupling cavity 7 is provided with 19 columns 10, and the 19 columns 10 are arranged in an H shape. The bodies 10 are arranged in 6 rows along the front-to-bac...

Embodiment 2

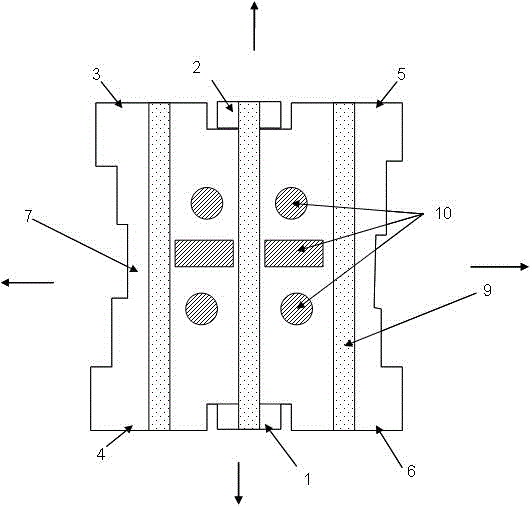

[0032] Such as figure 2 As shown, the only difference from Embodiment 1 is that the coupling cavity 7 has a protrusion on its width, and the direction of the protrusion points into the coupling cavity. Only 2 cylindrical columns 10 and 2 rectangular columns 10 are used. The loading conductor ridge 9 and metal ridge 8 are connected together without matching waveguide 11 . There is a gap greater than zero between adjacent columns 10 along the front-back axis of the input port 1 .

[0033] The above are examples only. In actual production, the side of the coupling cavity 7 can be one or more straight line segments, or a smooth curve, forming a rectangle, trapezoid or other more complex figures in the top view direction. The columnar body 10 can be rectangular, circular, elliptical, or other irregular shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com