High-pressure type accelerator

An accelerator, high-voltage technology, applied in accelerators, electrical components, etc., can solve the problems of increasing manufacturing costs and inability to reuse, and achieve the effect of improving overall performance, low cost, and high insulation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

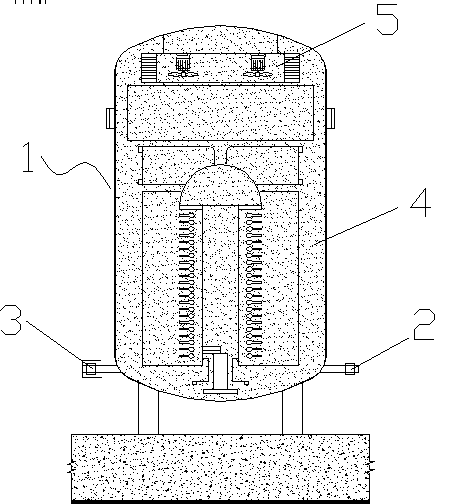

[0011] Such as figure 1 As shown, a high-voltage accelerator includes an accelerator main body 1, an air inlet 2 and an air outlet 3 are arranged on both sides of the lower end of the accelerator main body 1, and the inside of the accelerator main body 1 is filled with an insulating gas 4. Gas 4 is sulfur hexafluoride.

[0012] The accelerator body 1 is filled with sulfur hexafluoride as the insulating gas of the accelerator. Compared with the mixed gas of nitrogen and carbon dioxide, sulfur hexafluoride is an excellent electronegative gas, which can absorb electron energy and make electrons attach and eliminate The function of electrons, so it has high insulation ability and superior arc extinguishing performance. The insulation ability under the same pressure is 2.5 times that of air or nitrogen, and the arc extinguishing ability under one atmospheric pressure is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com