Mechanical-injection high-efficiency defoaming device

A technology of eliminating foam device and mechanical spraying, applied in the direction of degassed water/sewage treatment, etc., can solve problems such as liquid film rupture, and achieve the effect of low operating cost, convenient and flexible installation, operation and management, and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

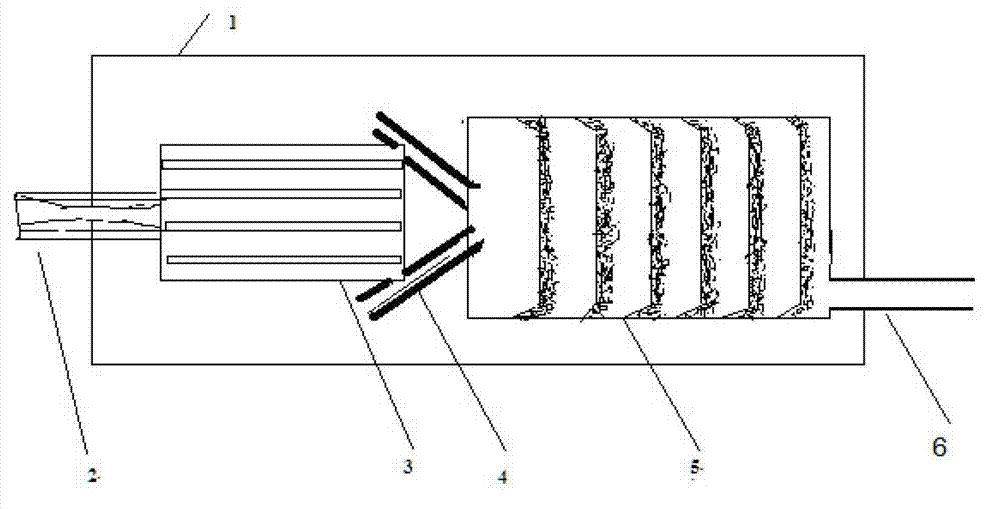

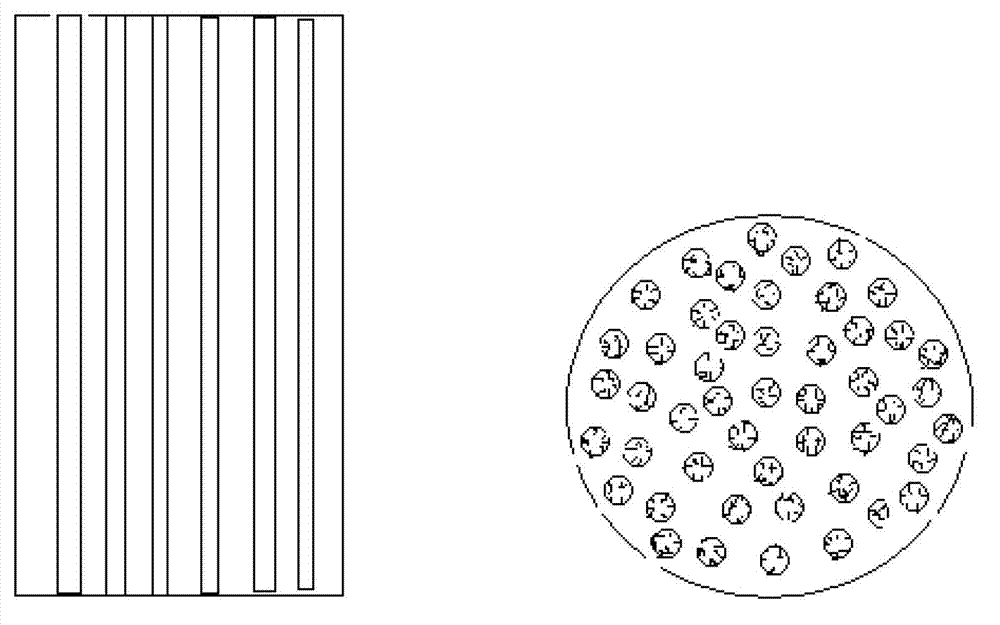

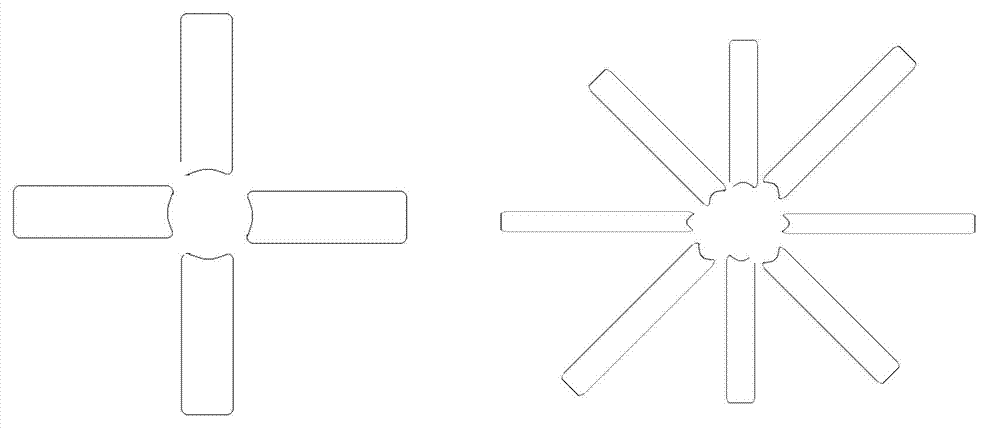

[0043] refer to figure 1 , the foam enters the Venturi tube through the inlet of the Venturi tube. The diameter of the foam suction port in the inlet circular tube section is 0.8 times the diameter of the foam outlet in the diffusion section. In the injection tube, the foam is stretched and Broken, and then enter the ceramic corrugated plate through four baffles, the fine bubbles are further spread on the filler, defoaming, and finally the liquid is discharged out of the main tank through the outlet.

Embodiment 2

[0045] refer to figure 1 , the foam enters the Venturi tube through the inlet of the Venturi tube. The diameter of the foam suction port in the inlet circular tube section is 1.0 times the diameter of the foam outlet in the diffusion section. In the injection tube, the foam is stretched and After being crushed, it enters the polypropylene orifice corrugated plate through eight baffle plates, and the fine bubbles are further spread on the packing, defoaming, and finally the liquid is discharged out of the main tank through the outlet.

Embodiment 3

[0047] refer to figure 1 , the foam enters the Venturi tube through the inlet of the Venturi tube. The diameter of the foam suction port in the inlet circular tube section is 1.2 times the diameter of the foam outlet in the diffusion section. In the injection tube, the foam is stretched and After being crushed, it enters the polypropylene wire mesh corrugated plate through eight baffle plates, and the fine bubbles are further spread on the packing, defoaming, and finally the liquid is discharged out of the main tank through the outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com