Quartz crucible for founding lanthanide series optical glass and method for founding lanthanide series optical glass slag clinker

An optical glass and quartz crucible technology, applied in glass manufacturing equipment, glass production, glass furnace equipment, etc., can solve the problems of increased production cost, high energy cost, corrosion of quartz crucible body, etc., so as to reduce energy cost and reduce erosion. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Quartz crucible of the present invention

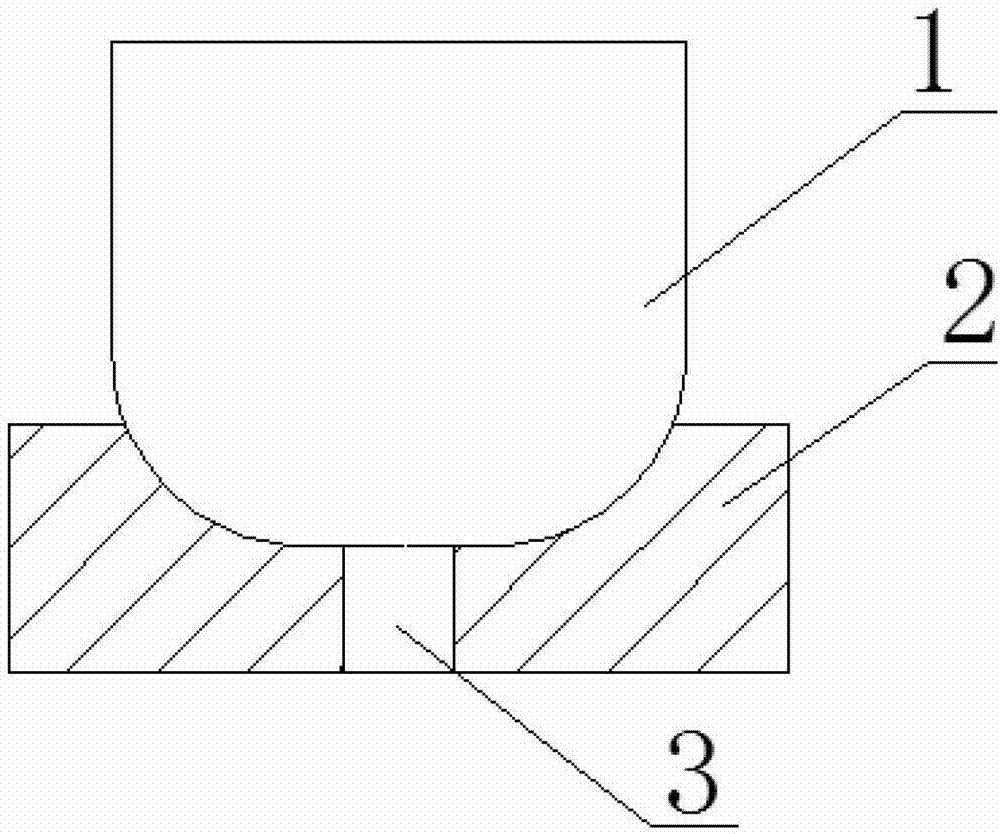

[0023] Such as figure 1 As shown, the present invention discloses a crucible for melting lanthanide optical glass, which includes a quartz crucible 1 and a refractory base 2 located at the bottom of the quartz crucible 1 .

[0024] Preferably, the upper surface of the refractory base 2 is provided with a groove matching the shape of the bottom of the quartz crucible 1, the bottom of the quartz crucible 1 is embedded in the refractory base 2, and the height of the top of the refractory base 2 is lower than that of the quartz crucible 1. a quarter.

[0025] Preferably, there is a channel 3 connecting the bottom of the quartz crucible 1 inside the refractory base 2, so as to make the heating more uniform and reduce heat loss.

[0026] Further, the bottom surface and the side surface of the quartz crucible 1 are rounded transitions.

Embodiment 2

[0027] Embodiment 2 The method for melting lanthanide optical glass slag clinker of the present invention

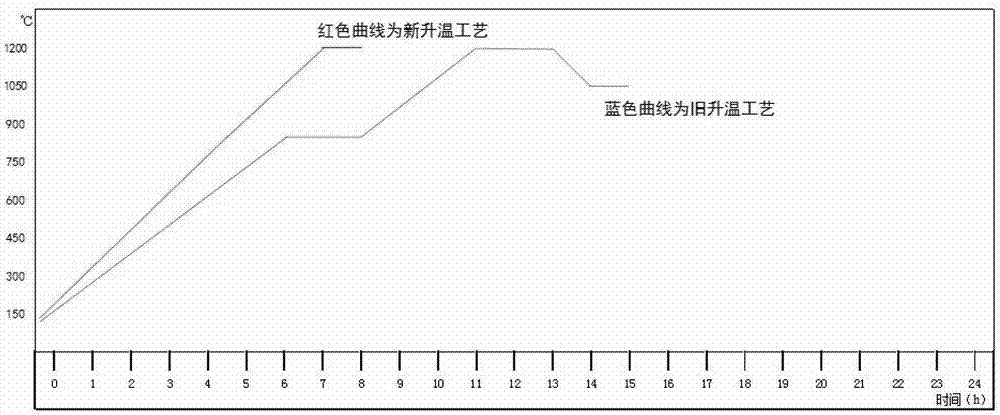

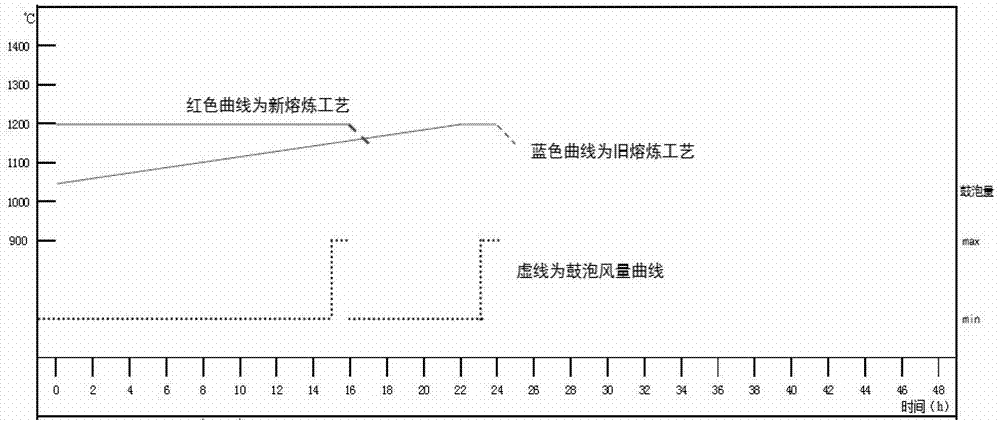

[0028] From room temperature to 800°C, the heating time is about 4.5 hours, and then from 800°C to the feeding temperature of 1200°C, the heating time is about 2.5 hours, and the powder is put into the melting after holding at 1200°C for 1 hour. The heating time is about 8 hours in total. After starting to feed, keep feeding at a constant temperature of 1200°C. The feeding time is about 15 hours. After adding the powder, keep it warm for half an hour, then put it into the bubbler to start bubbling, the bubbling time is half an hour, and the total time of the melting stage is about 16 hours. After the bubbling is completed, the melted molten glass is released to complete the production. Put two batches of powder into a single furnace for smelting, that is, heat up once and smelt twice, and the total time of a single furnace is about 40 hours.

Embodiment 3

[0029] Embodiment 3 The method of melting the lanthanide optical glass slag clinker of the present invention is compared with the old technology

[0030] The old heating and melting process: using the quartz crucible described in the patent application number: 200920082682. 3 hours, keep warm at 1200°C for 2 hours, then cool down to the initial feeding temperature of 1050°C, cool down for about 1 hour, keep warm at 1050°C for 1 hour, and then start to put in powder for melting. The heating time is about 15 hours in total. After starting to feed, the temperature will gradually rise during the feeding process. The feeding time is about 22 hours. After the powder is added, keep warm for 1 hour, and then put it into the bubbler to start bubbling. The bubbling time is 1 hour. The total time of the melting stage is about 24 hours. After the bubbling is completed, the molten glass is released to complete the production. Put two batches of powder into a single furnace for smelting, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com