Laser-cladded oil well pipe subjected to multicomponent cementation compound treatment and production process and device

A technology of laser cladding and multi-component co-infiltration, which is applied in the direction of metal material coating process, drill pipe, casing, etc., can solve the problems of lower production efficiency, poor wear resistance, and increased production costs, so as to improve wear resistance and Anti-corrosion, improved service life, and remarkable benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

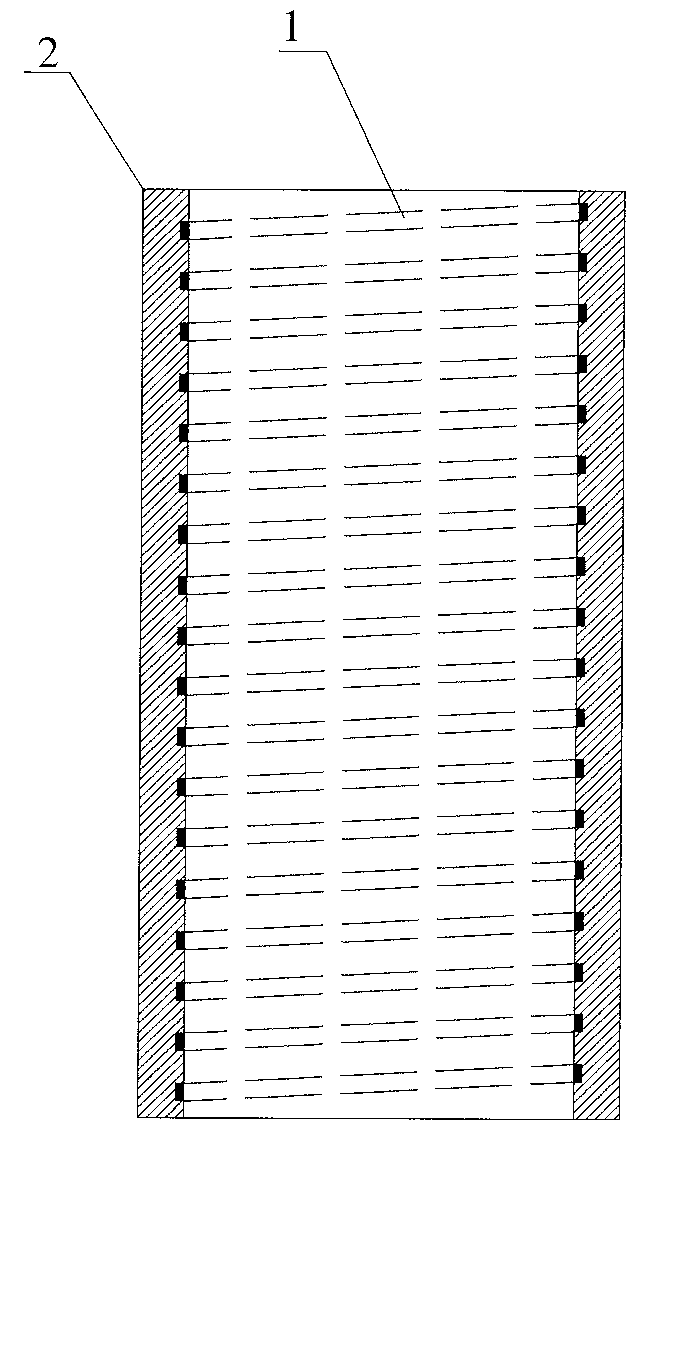

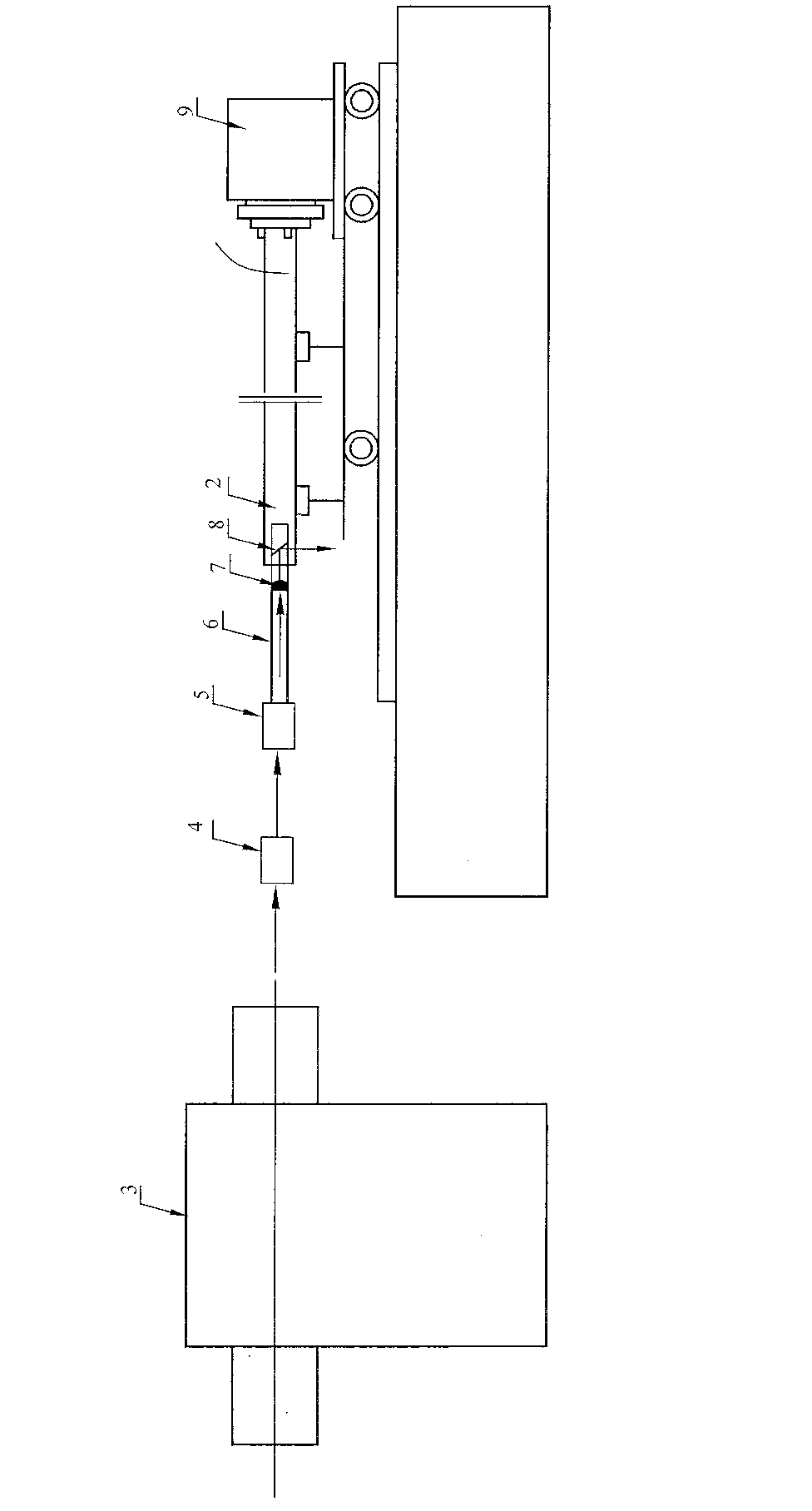

[0038] see figure 1 , figure 2 Shown:

[0039] The oil well pipe 2 treated by laser cladding multi-component co-infiltration composite treatment according to the present invention has a laser cladding heat treatment layer 1 on the surface multi-component co-infiltration composite layer. Such laser modification technology performs laser composite treatment on the inner surface of the oil well pipe 2 of the corresponding steel grade through C, N, O, S multi-component co-infiltration to obtain the corresponding surface structure of the oil well pipe 2, which can improve the mechanical properties of the inner surface of the oil well pipe 2 , metallurgical properties, and physical properties, thereby improving a series of properties such as wear resistance, corrosion resistance, and fatigue resistance of the oil well pipe 2.

[0040] The production process of the oil well pipe treated by laser cladding multi-component co-infiltration composite treatment according to the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com