Electrolysis hydrogen furnace

A hydrogen and electrolyzer technology, applied in the electrolysis process, electrolysis components, household stoves/stoves, etc., can solve the problems of difficulty in supplying the energy consumption of stoves and kitchens, and the difficulty of electric stoves in meeting the release of high power in a short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

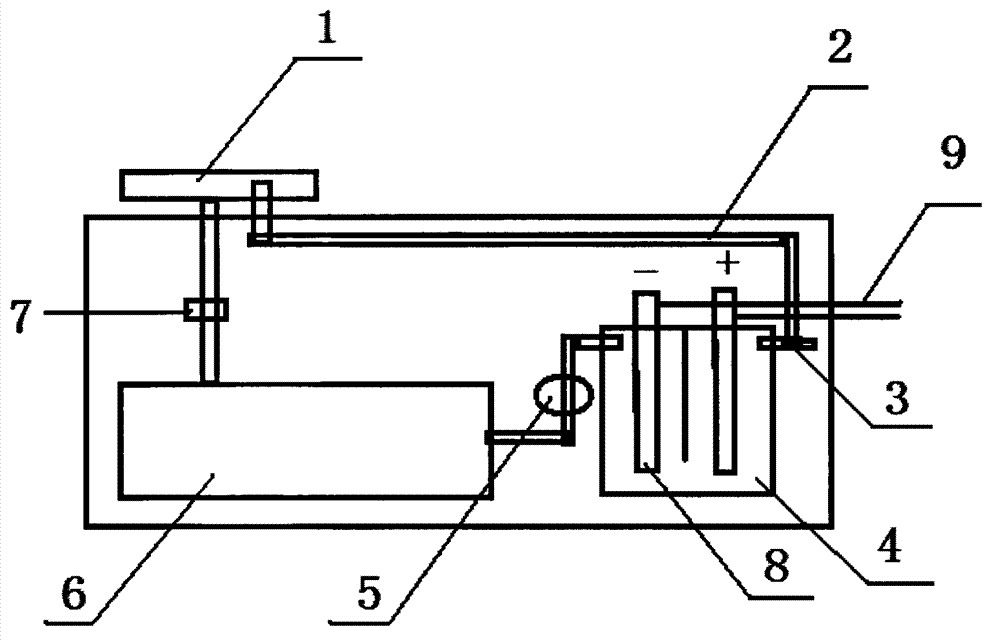

[0008] Below in conjunction with the accompanying drawings the present invention is further described: after the DC power supply 9 is energized, oxygen is condensed on the positive electrode of the electrolysis, and the oxygen conduit 2 is exported, and released through the three-way valve 3 or enters the hydrogen combustion stove 1 through the oxygen conduit 2 to support combustion, electrolysis The negative electrode 8 is filled with hydrogen, stored in the hydrogen pressure storage tank 6 through the micro compressor 5, and enters the hydrogen combustion stove 1 for combustion through the pressure reducing valve 7 during use.

[0009] In the preferred solution, the water participating in the electrolytic decomposition is alkaline water, so as to avoid the release of acid gas and pollute the environment.

[0010] The furnace of the present invention can supply 0.5-50m3 / day of hydrogen, and can be used in small and medium-sized canteens, boilers and other places to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com