A steel truss arc shed for tunnel entrances in alpine permafrost

A steel truss and steel pipe truss technology, applied in the structural field of steel truss arc sheds, can solve the problems of large and unrealistic slope top spans, achieve the effect of slowing down the melting speed and ensuring the overall construction period target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

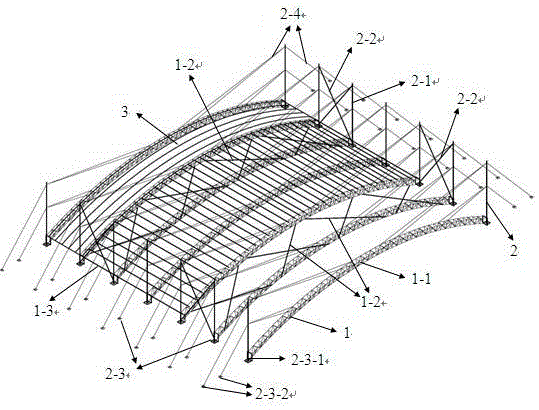

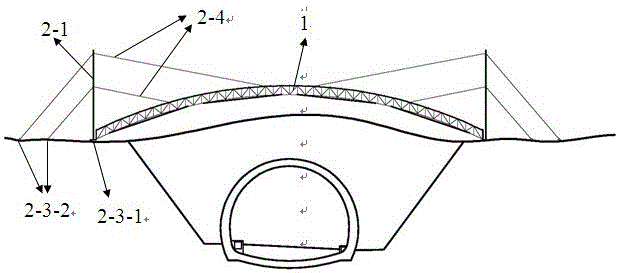

[0038] A steel truss arc shed for tunnel openings in alpine permafrost, comprising a main truss structure 1, a supporting connection structure 2 and a roof structure 3. Both ends of the main truss structure 1 are supporting connection structures 2 , and the space between adjacent main truss structures 1 is a roof structure 3 .

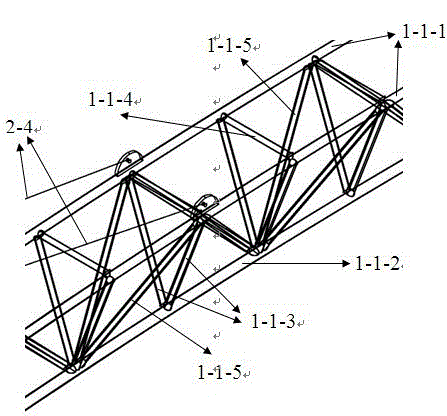

[0039] Such as figure 1 There are roof purlins 1-3 and roof structure 3 between all steel pipe trusses 1-1. In order to make it easier to see the structure of the steel truss arc shed, some steel pipe trusses 1-1 do not draw roof purlins 1-3 and roof structure3. The main truss structure 1 is composed of seven inverted triangular steel pipe trusses 1-1, sixteen truss rods 1-2 and roof purlins 1-3. The upper part of the steel pipe truss 1-1 is composed of two φ76mm×2.5mm 1# steel pipes 1-1-1, and the lower part is arranged into an inverted structure with a top width of 600mm and a height of 800mm by a φ89mm×2.5mm 2# steel pipe 1-1-2. Isosceles triangl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com