Transmission control device

A controller and gearbox technology, applied in transmission control, cooling/ventilation/heating transformation, electrical equipment enclosure/cabinet/drawer, etc., can solve problems such as high cost and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

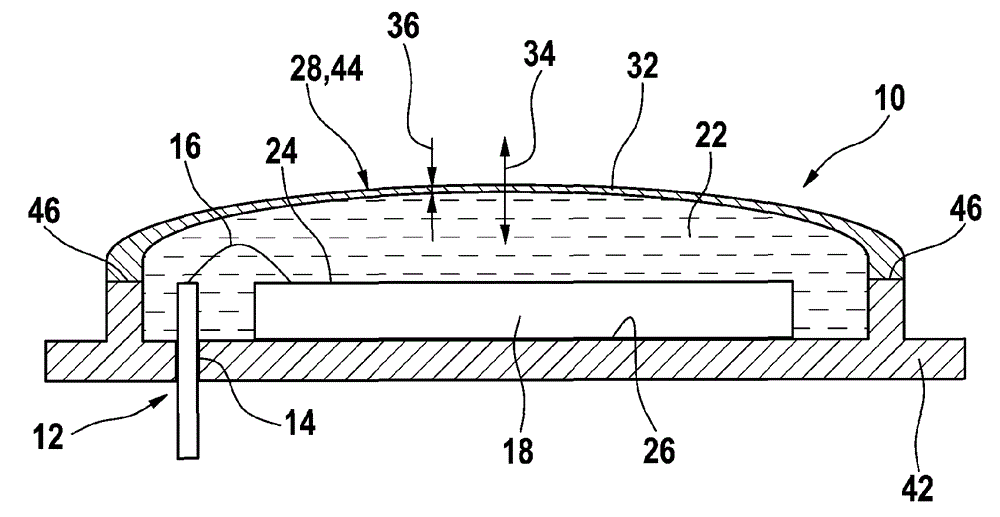

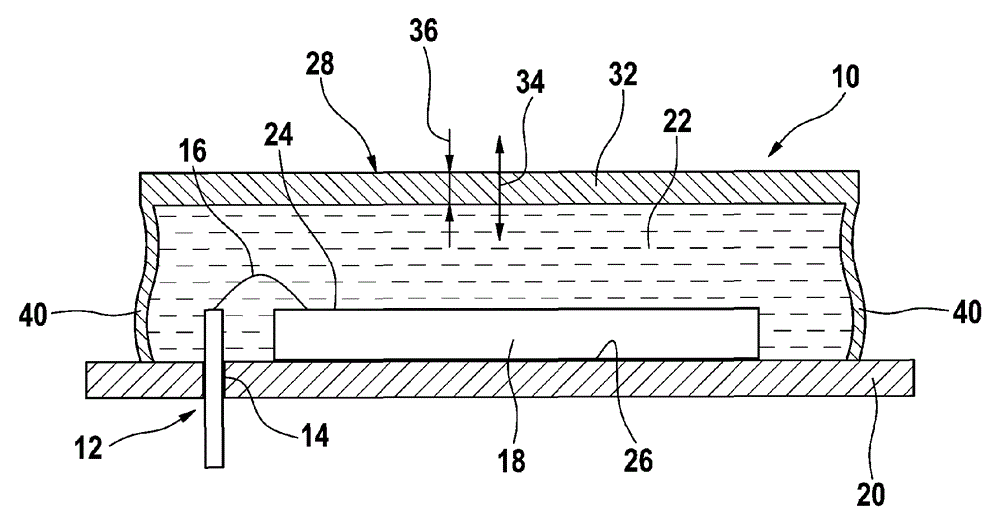

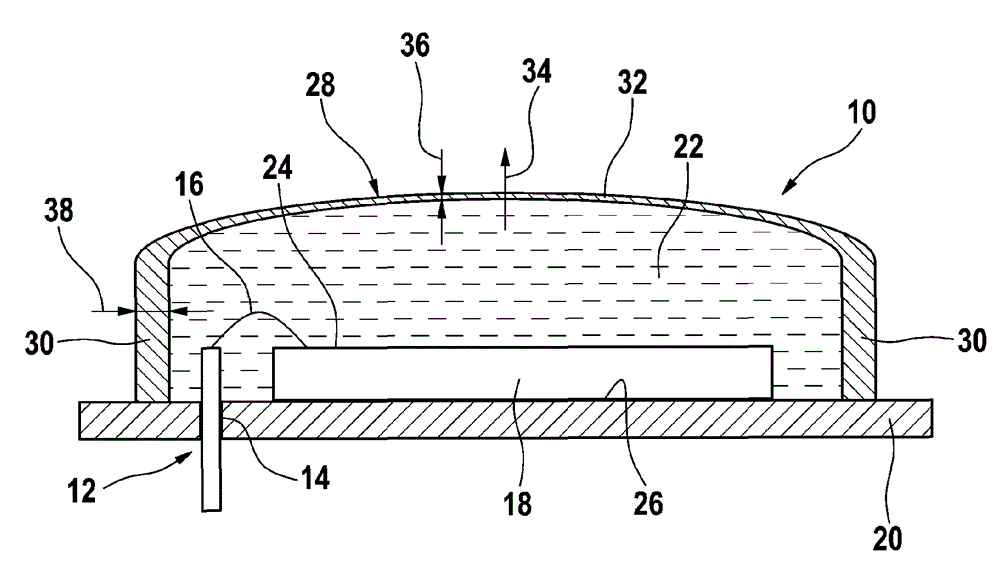

[0019] according to figure 1 The diagram in FIG. 1 shows a first embodiment variant of the controller provided according to the invention.

[0020] from according to figure 1 It can be seen in the illustration that an integrated controller, in particular a controller for a gearbox or an automatic gearbox of a motor vehicle, has at least one pin-shaped feed-through in the bottom part 20, which is preferably composed of Made of plastic material. The individual pin-shaped feedthroughs 12 are electrically insulated from one another, wherein the pin-shaped feedthroughs 12 are designed to be solderable or laser weldable and to enable a crimp connection. The pin-shaped feedthroughs 12 are either inserted into the base part 20 made of plastic or sprayed into the base part by means of the seal 14 . The pin-shaped feedthrough 12 is connected via an electrical connection 16 to an electrical component, which is arranged on the upper side of the circuit carrier 18 . The bottom part 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com