Light field imaging device and image processing device

一种光场摄像、摄像面的技术,应用在三维摄像技术领域,能够解决无法同时获得高分辨率图像和深度信息等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

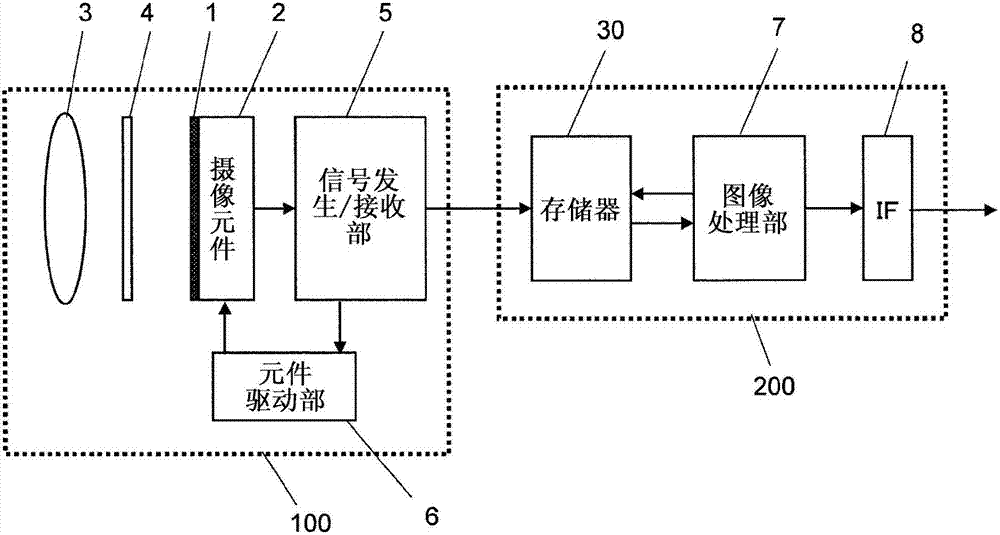

[0055] First, an imaging device according to a first embodiment of the present invention will be described. figure 1 It is a block diagram showing a schematic configuration of a light field imaging device (hereinafter, simply referred to as "imaging device") according to this embodiment. The imaging device of this embodiment is a digital electronic camera, and includes an imaging unit 100 and a signal processing unit 200 that generates a signal (image signal) representing an image based on a signal generated by the imaging unit 100 .

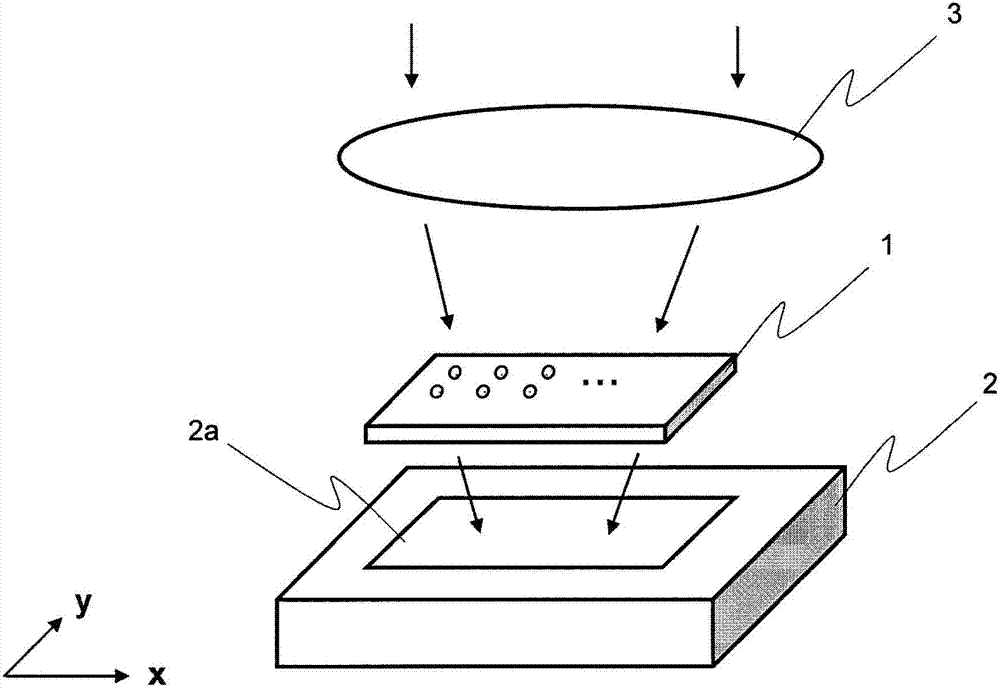

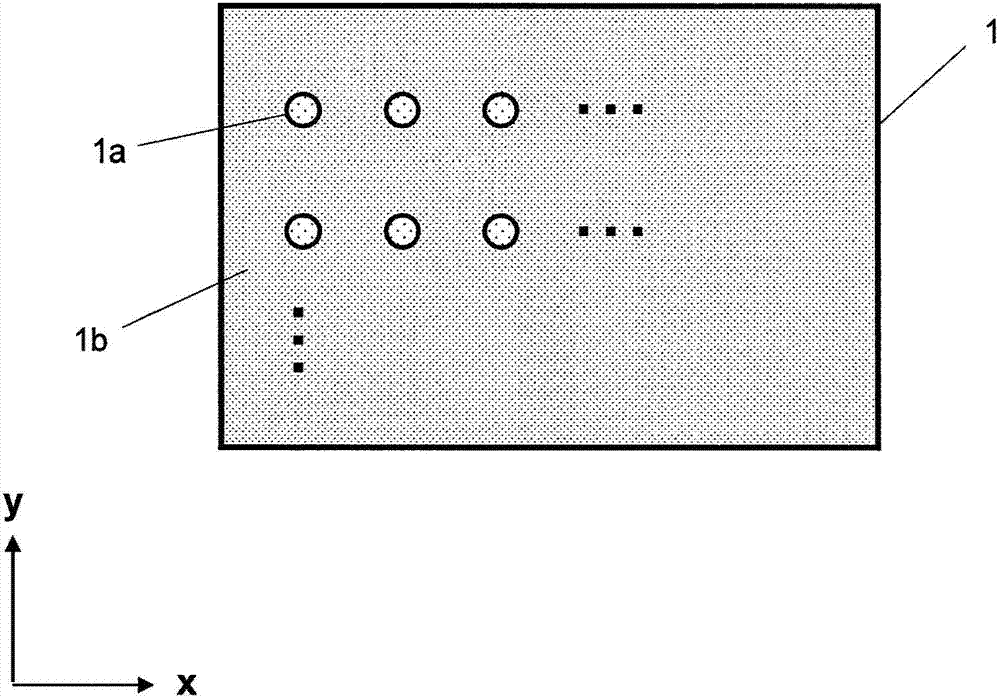

[0056] The imaging section 100 includes the following: a color solid-state imaging element 2 (hereinafter simply referred to as "imaging element") having a plurality of photosensitive elements arranged on an imaging surface; Light-transmitting plate 1 (light-transmitting part) of two kinds of light-transmitting areas different from each other; circular optical lens 3 (imaging part) for forming an image on imaging surface 2a of imaging element 2;...

Embodiment approach 2

[0121] Next, a second embodiment of the present invention will be described. In this embodiment, the primary color configurations of the optical lens 3 and the imaging element 2 are different from those of the first embodiment described above, but are the same as those of the first embodiment. Hereinafter, the description will focus on points different from Embodiment 1, and the description of the same matters will be omitted.

[0122] Figure 7 It is a figure which shows the imaging state of the optical lens 3 of this embodiment. In the present embodiment, the optical lens 3 has different focal lengths between the peripheral portion 3a and the central portion 3b. The focal length is relatively short in the lens peripheral portion 3a, and the focal length is relatively long in the lens central portion 3b. Based on this characteristic, the subject is brought into focus on the light-transmitting plate 1 with respect to the lens peripheral portion 3a, and the subject is brough...

Embodiment approach 3

[0129] Next, a third embodiment of the present invention will be described. In this embodiment, on the light-incident side surface (front face) of the optical lens 3 of Embodiment 2, two kinds of light-transmitting lenses having the same spectral transmittance characteristics as the two kinds of light-transmitting regions of the light-transmitting plate 1 are arranged. member. Specifically, as Figure 9 As shown, in front of the peripheral portion 3a of the lens 3, a light-transmitting member 1aa having the same spectral transmittance characteristics as the light-transmitting region 1a of the light-transmitting plate 1 is disposed, and in front of the central portion 3b of the lens 3, a light-transmitting member 1aa is disposed. A light-transmitting member 1bb having the same spectral transmittance characteristic as that of the light-transmitting region 1b of the light-transmitting plate 1 was obtained. Other configurations and processes are the same as those in Embodiment 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com