Numerical-control large-scale precise dual-drive gap removing rotating working table

A technology of rotary workbench and workbench, which is applied in the direction of large fixed members, manufacturing tools, transmission devices, etc., can solve the problems of reducing transmission clearance, machine scrapping, vibration, etc., and achieve the effect of prolonging service life and improving transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

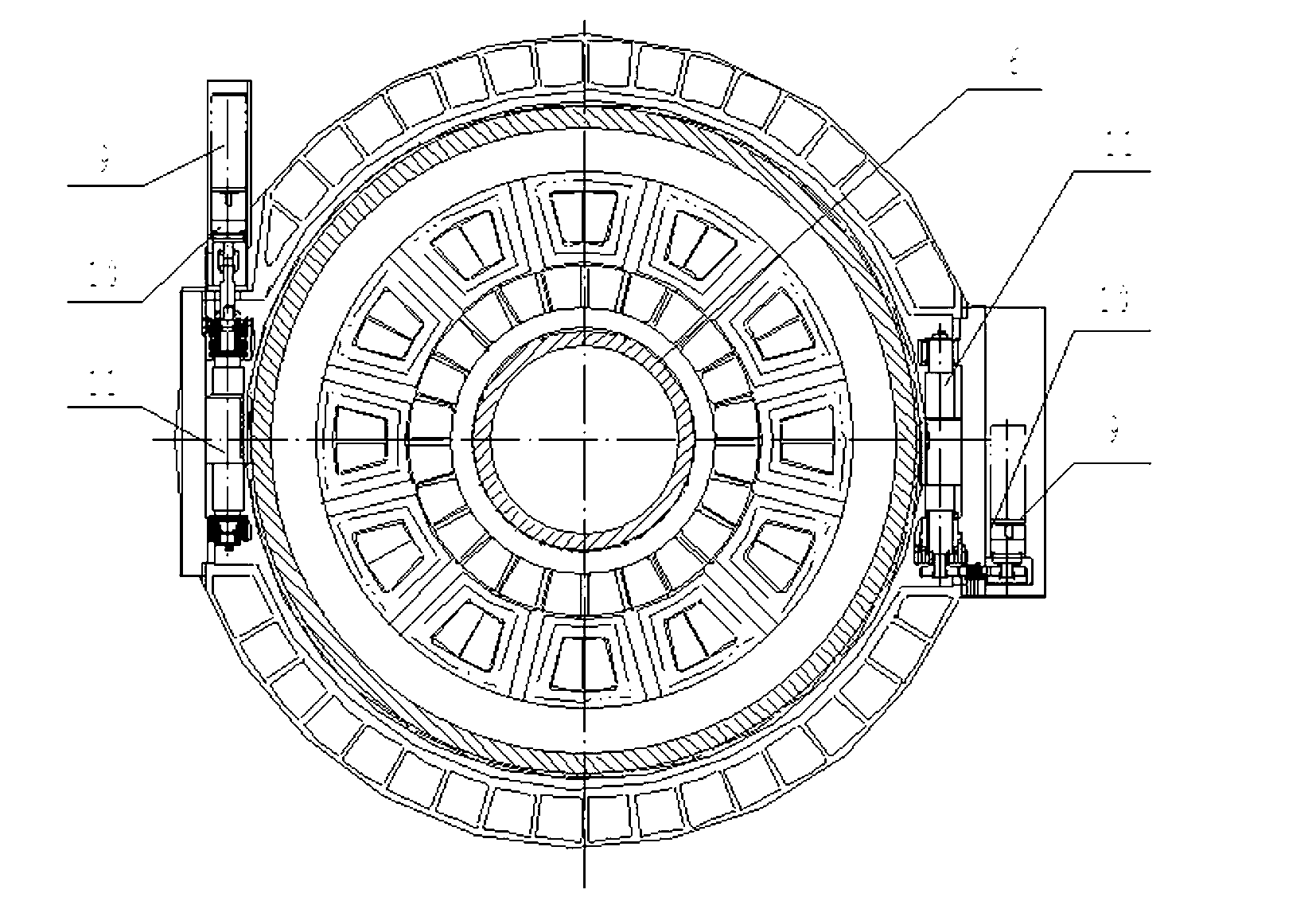

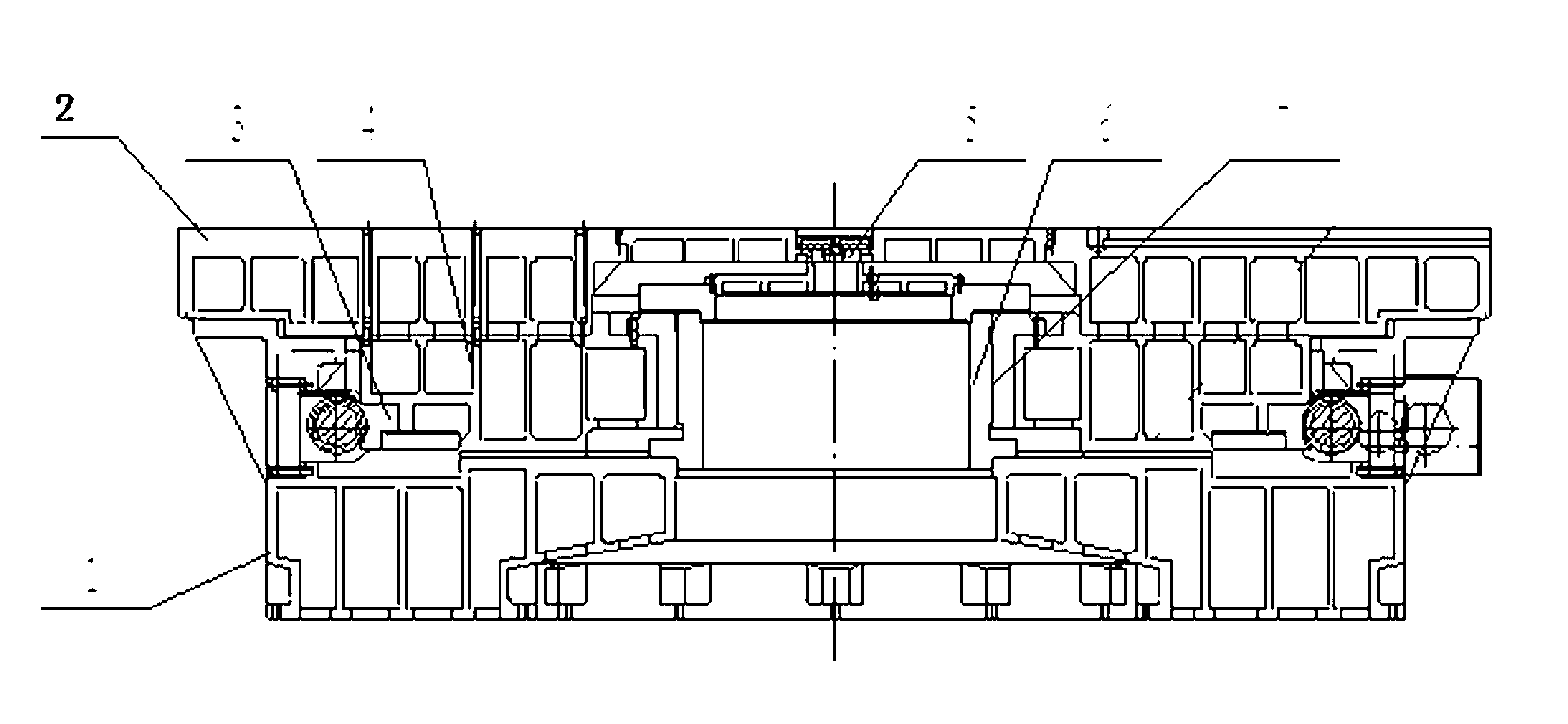

[0013] Such as figure 1 with figure 2 As shown, a numerically controlled large-scale precision dual-drive anti-backlash rotary table includes a table body 1, and a hollow spindle 6 and a worm wheel hub 4 arranged on the table body 1, and the hollow spindle 6 is provided with a code 5, the worm wheel hub 4 can rotate around the hollow main shaft 6 through a radial support 7, a worm wheel 3 is fixedly connected to the worm wheel hub 4, and both sides of the table body 1 are respectively provided with worms connected in sequence 9. Planetary gearbox 10 and servo motor 11. The worms 9 on both sides of the table body 1 mesh with the worm gear 3 to form a dual drive structure that provides driving torque at the same time, or a du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com