Three-cylinder hot-air engine

A hot gas engine and cylinder technology, applied in hot gas variable displacement engine devices, machines/engines, mechanical equipment, etc., can solve problems such as heat loss and low fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

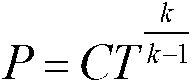

[0092] Such as figure 1 The three types of door hot gas engines shown include two cylinder-piston mechanisms: cylinder-piston mechanism A1 and cylinder-piston mechanism B3, the cylinders of the two cylinder-piston mechanisms are provided with air inlets 11 and exhaust ports 12, and Both cylinder-piston mechanisms are provided with a combustion chamber 5, each of the air inlets 11 is provided with a corresponding intake valve 110, and each of the exhaust ports 12 is provided with a corresponding exhaust valve. Door 120; a reciprocating flow port A13 and a reciprocating flow port B14 are set on the cylinder of the cylinder-piston mechanism A1, a reciprocating flow port C33 and a reciprocating flow port D34 are set on the cylinder of the cylinder-piston mechanism B3, and the reciprocating flow port A13, the reciprocating flow port B14, the reciprocating flow port C33 and the reciprocating flow port D34 are provided with corresponding reciprocating flow control doors, and the rec...

Embodiment 2

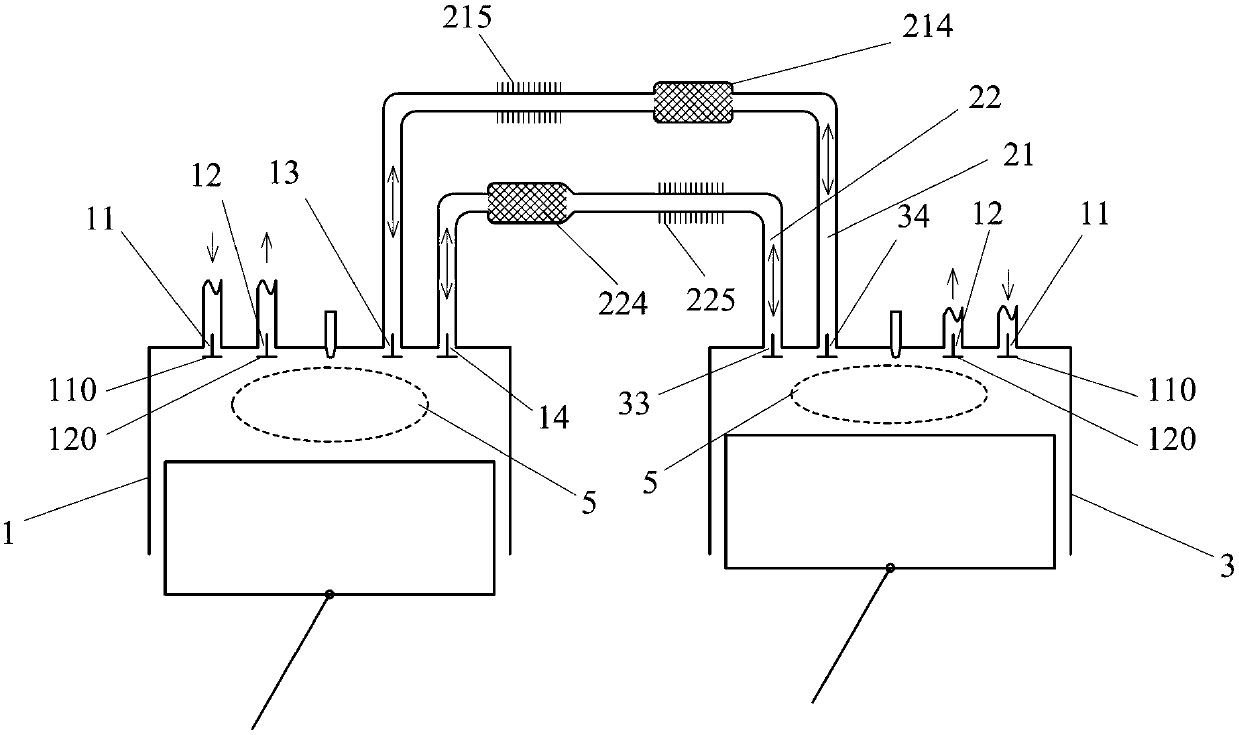

[0095] Such as figure 2 The difference between the shown three-type door hot gas engine and Embodiment 1 is that the air intake port 11 and the exhaust port 12 on the two cylinder-piston mechanisms are integrally arranged as a shared air port 121 for intake and exhaust. , the intake and exhaust common air port 121 is provided with a corresponding intake and exhaust common air valve 122 .

Embodiment 3

[0097] Such as image 3 The difference between the three types of door hot gas engines shown in Embodiment 2 is that: the reciprocating flow port A13 and the reciprocating flow port B14 are integrated into a reciprocating flow port E15, and the reciprocating flow port C33 and the reciprocating flow port C33 The flow port D34 is integrally set as a reciprocating flow port F35, and the reciprocating flow port E15 communicates with one end of the reciprocating communication channel A21 and one end of the reciprocating communication channel B22 through the reciprocating channel 23 at the same time, and the reciprocating flow port F35 passes through the reciprocating channel 23. Another reciprocating passage 23 communicates with the other end of the reciprocating communication passage A21 and the other end of the reciprocating communication passage B22 at the same time; two control valves are respectively arranged on the reciprocating communication passage A21 and the reciprocating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com