Vehicle Lamps

A technology for vehicles and lamps, which is applied to road vehicles, motor vehicles, lighting and heating equipment, etc., can solve the problems of reduced light utilization efficiency and low light utilization efficiency, and achieve the effect of improving light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

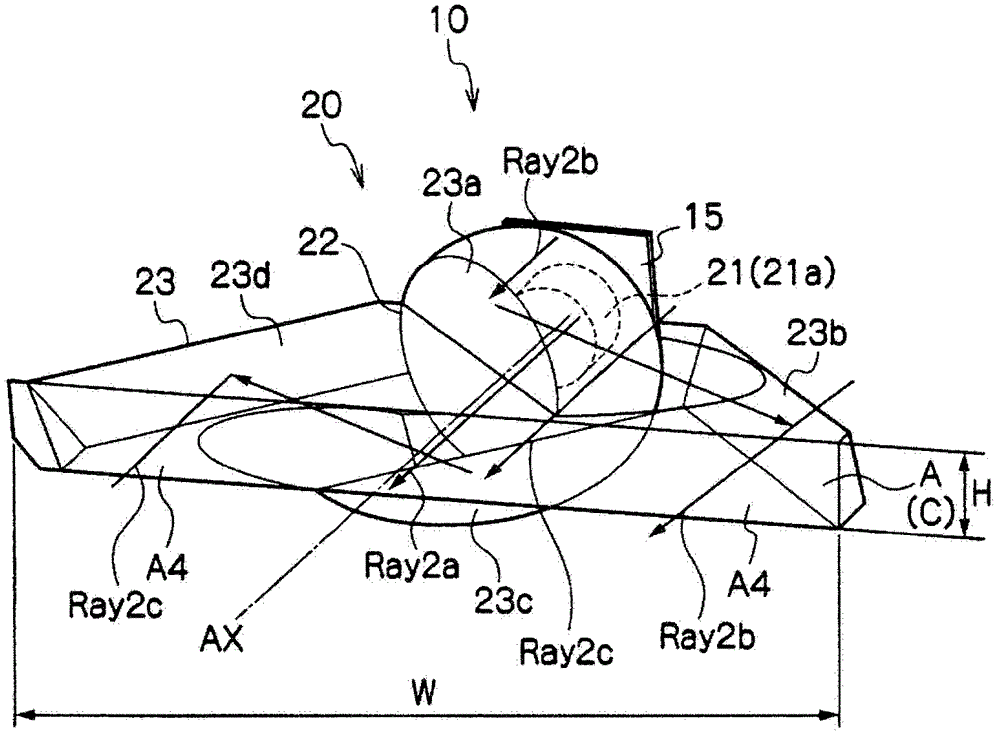

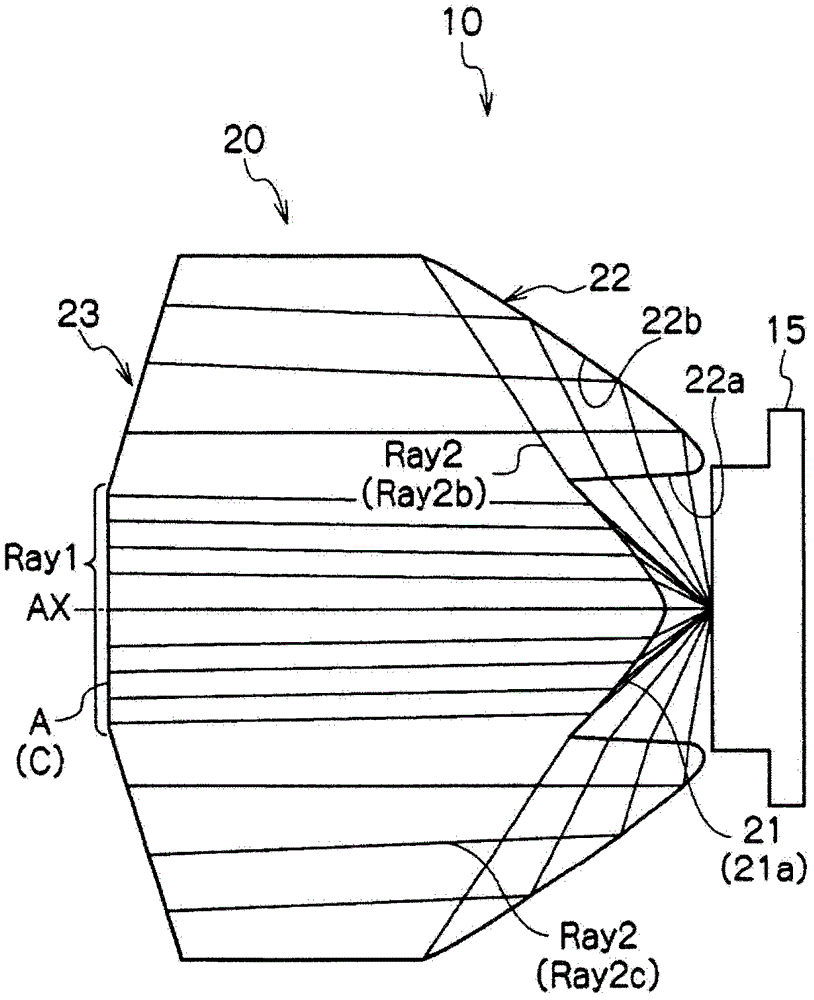

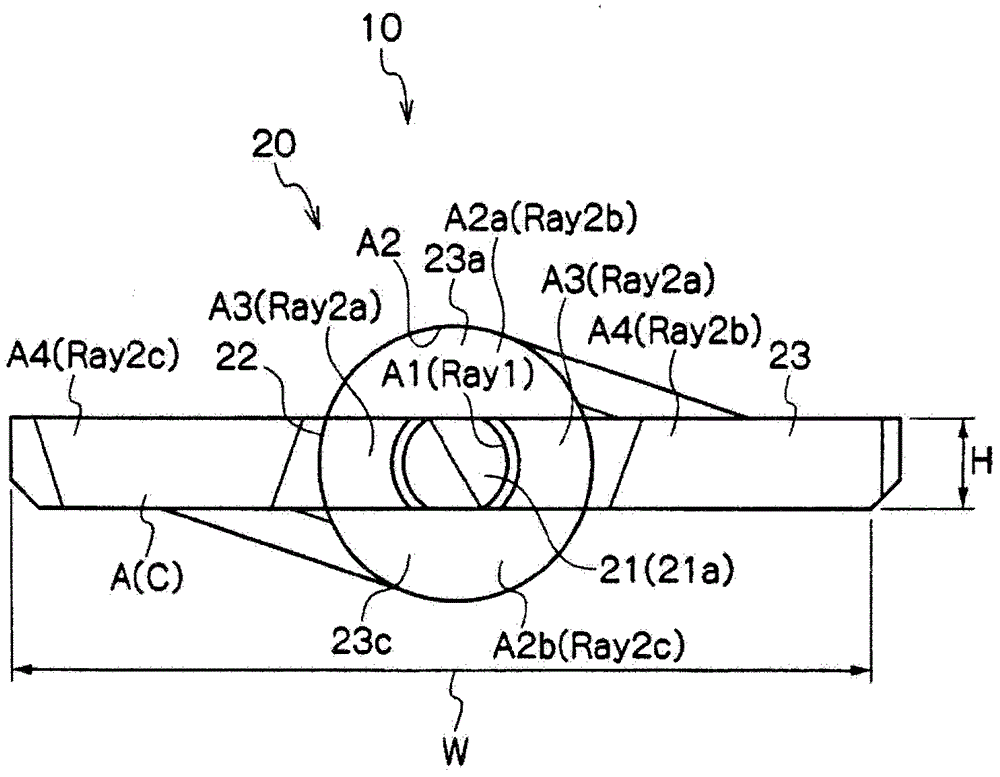

[0064] Next, a vehicle lamp as an embodiment of the present invention will be described with reference to the drawings.

[0065] The vehicle lamp unit 10 of the present embodiment is suitable for automotive signal lamps (tail lamps, stop lamps, blinkers, daytime running lamps, position lamps), and as Figure 1 ~ Figure 3 As shown, the vehicular lighting unit 10 includes an LED light source 15 , a lens body 20 disposed in front of the LED light source 15 for incident light emitted by the LED light source 15 , and the like.

[0066] [LED light source 15]

[0067] The LED light source 15 is, for example, coated with or fixedly connected with a phosphor (yellow) that emits light when excited by the light-emitting wavelengths of a plurality of light-emitting chips (blue) on a light source package mounted with a plurality of light-emitting chips (blue), and utilizes the above-mentioned blue light. A surface light source that emits white light and yellow light. In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com