A lean-fuel premixed pre-evaporative low-pollution combustor with main-stage fuel direct injection

A combustion chamber and pre-evaporation technology, which is applied in the field of aero-engines, can solve the problems of difficulty in meeting the requirements of low pollution emission, more pollutants, and low combustion efficiency, and achieve a stable and reliable ignition source, reduce pollutant emissions, and stabilize the ignition source. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

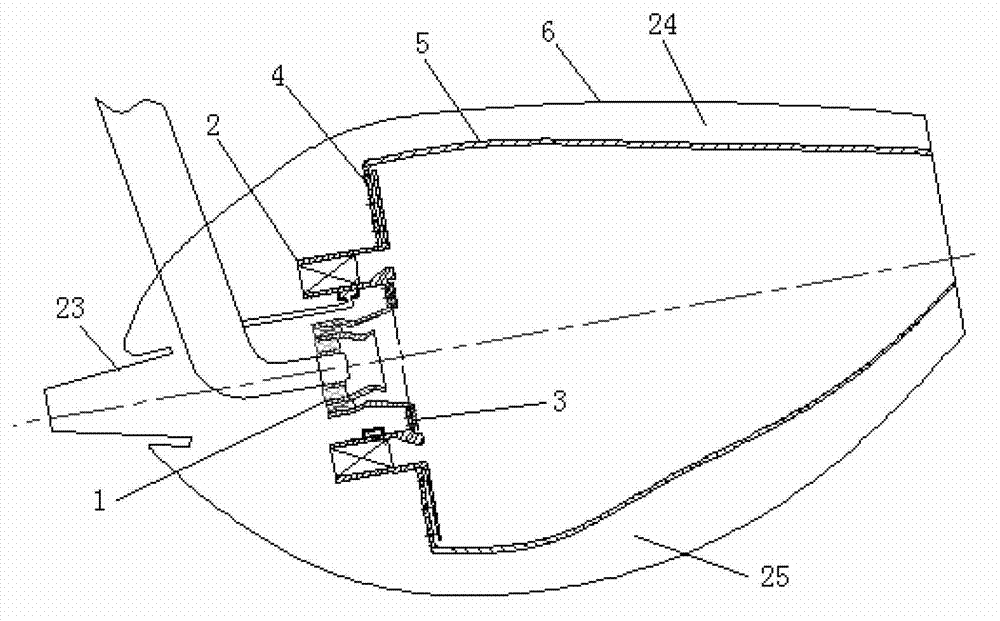

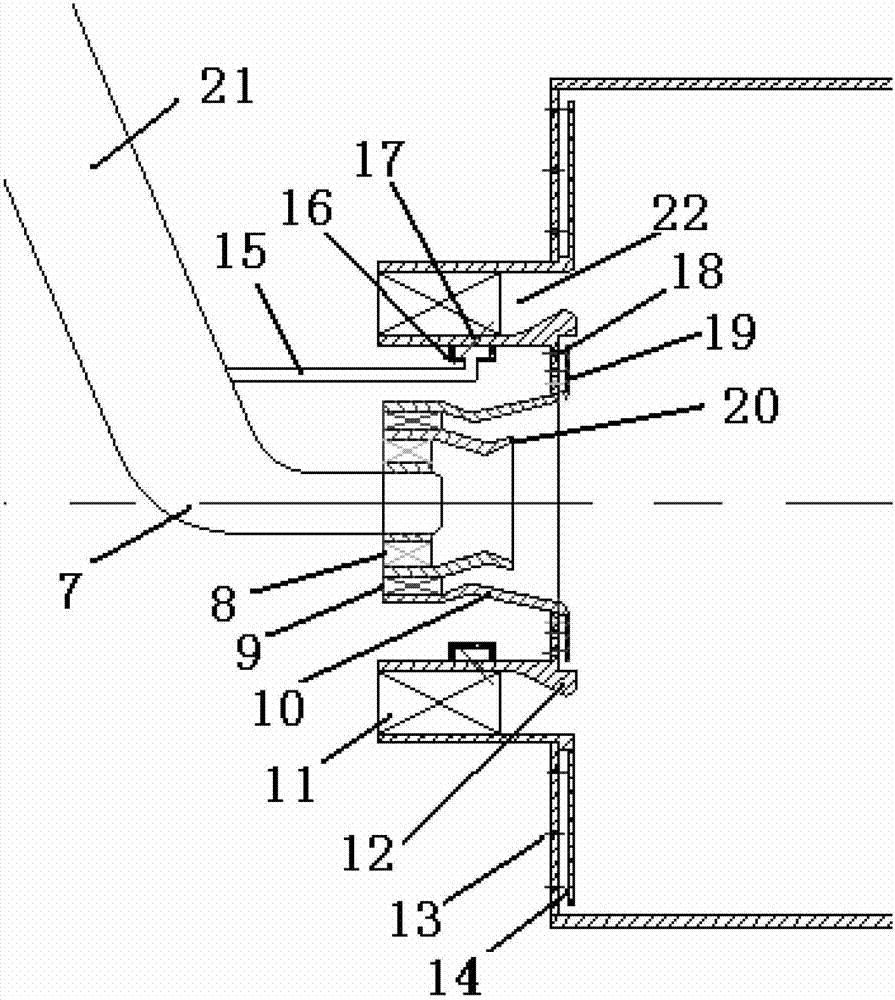

[0028] A lean-fuel premixed pre-evaporation low-polluting combustion chamber with primary fuel direct injection in this embodiment is as follows: figure 1 , 2 As shown, it includes the combustion chamber head, the flame tube 5, the combustion inner ring channel 25, the combustion outer ring channel 24, the fuel injection rod 21 and the casing, the fuel injection rod 21 is installed on the casing 6, and on the one hand is the combustion chamber The head supplies oil, and on the other hand bears part of the mechanical force. The head of the combustion chamber is connected to the casing 6 through the fuel injection rod 21, while the head of the combustion chamber, the inner ring channel 25 of the combustion chamber and the outer ring channel 24 of the combustion chamber are distributed according to the flow distribution law. Design, the air in the inner and outer ring passages enters the flame cylinder from the mixing hole and the air film cooling hole on the flame cylinder 5 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com