A gas turbine low-emission combustor using gaseous fuel

A gas fuel, gas turbine technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of lack of adaptability of gas fuel, engine combustion chamber damage, prone to spontaneous combustion and backfire, etc., to achieve stable combustion and prevent Good effect of tempering and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

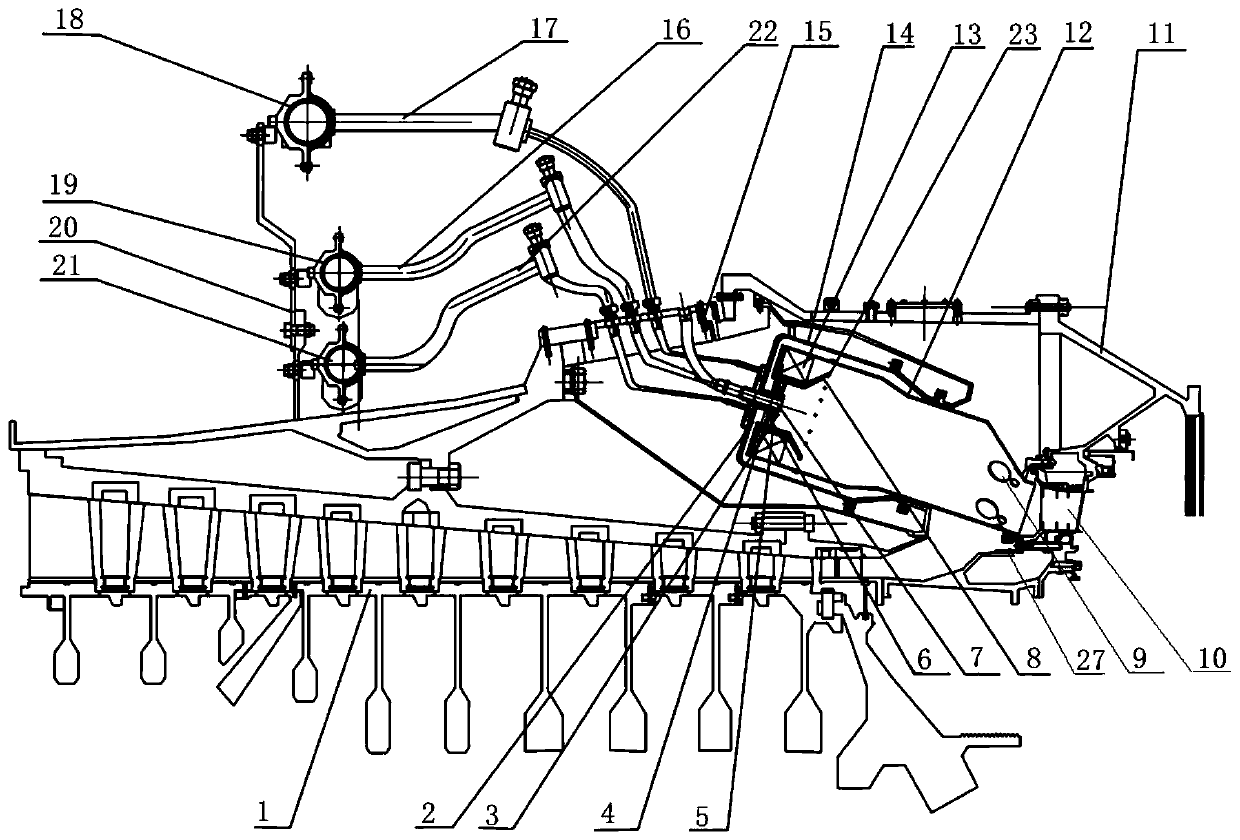

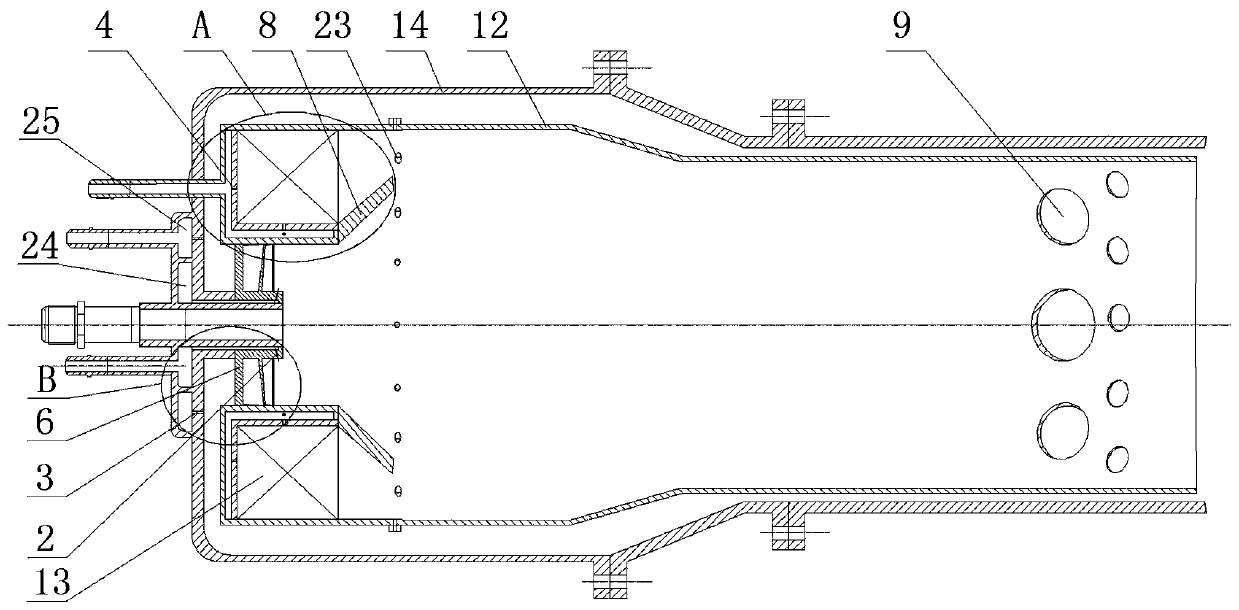

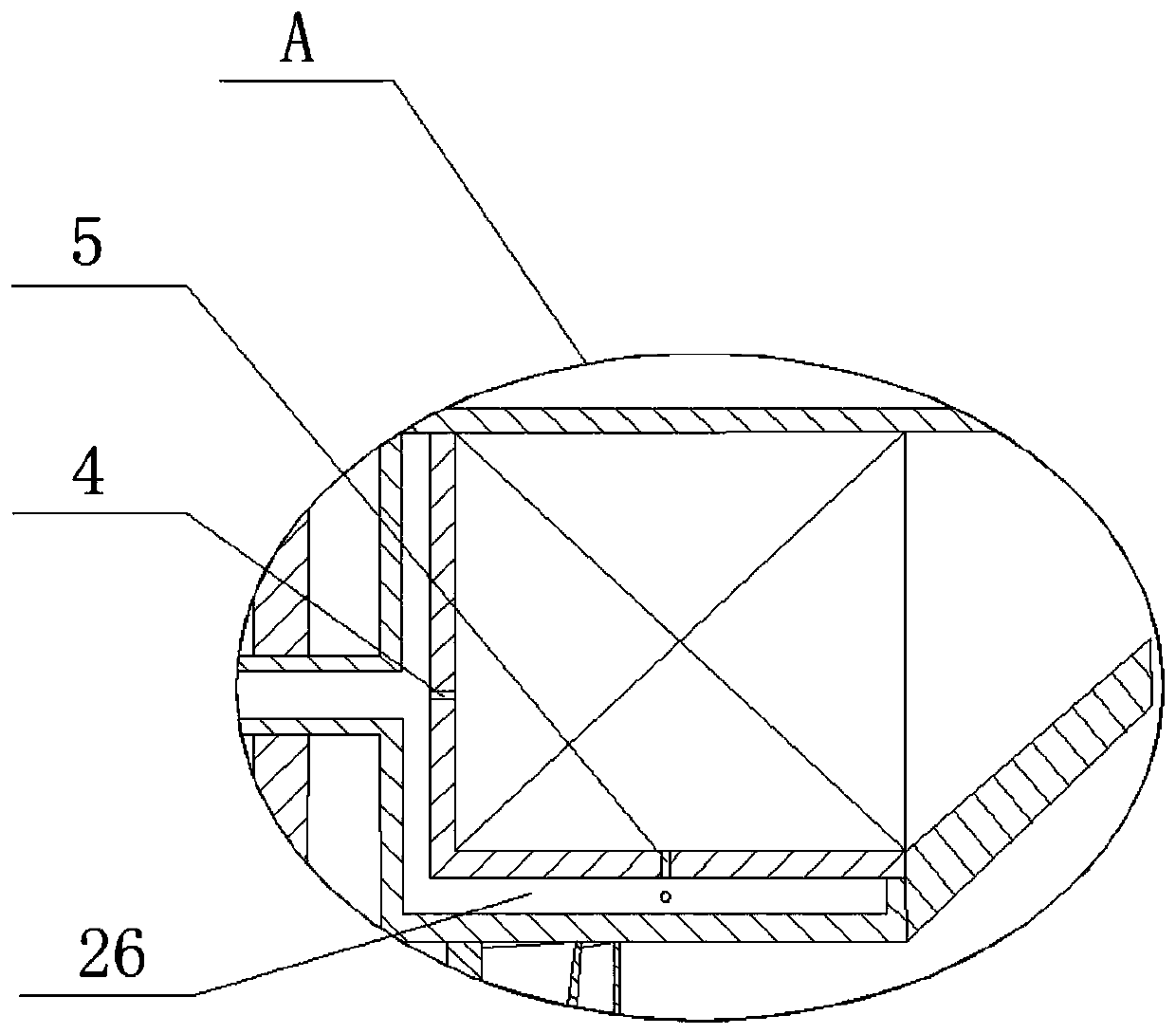

[0033] like Figure 1-Figure 4 As shown, a gas turbine low-emission combustor using gas fuel, the combustor head includes a duty stage and a main combustion stage arranged in a concentric manner, and the duty stage is in the center, and the main combustion stage is arranged at the periphery of the duty stage. Combustion stability and low emissions when using gaseous fuel is achieved by adjusting the fuel distribution of the duty stage, the main combustion stage including the first-stage axial swirler 6 and the duty stage fuel nozzles and the coordination between the different nozzles , the first-stage axial swirler 6 is installed in the central hole of the head of the flame tube 12, the outer casing 14 of the flame tube is installed outside the flame tube 12, and the flame tube 12 is arranged coaxially with the outer casing 14 of the flame tube, The outer casing 14 of the flame cylinder is respectively provided with a No. 1 duty fuel tank 24 and a No. 2 duty grade fuel tank 25...

Embodiment 2

[0039] like Figure 5 and Image 6 As shown, the outer casing 14 of the flame tube is located in the outer ring part of the high-pressure igniter 7 and close to one end of the first-stage axial swirler 6. The No. 2 duty fuel nozzles 3 are evenly arranged in the circumferential direction, and the No. The axial angle between the axis of the nozzle 3 and the first-stage axial swirler 6 is 60°. Other structures and connection methods are the same as those in Embodiment 1.

Embodiment 3

[0041] The installation angle between the center line of the flame tube 12 and the engine center line is 30°. Other structures and connection methods are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com