multipurpose burner

A burner and multi-purpose technology, applied in the field of combustion equipment, can solve the problems of large toxic and harmful gases, insufficient combustion, low combustion efficiency, etc., and achieve the effect of strengthening atomization effect, improving atomization effect, and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

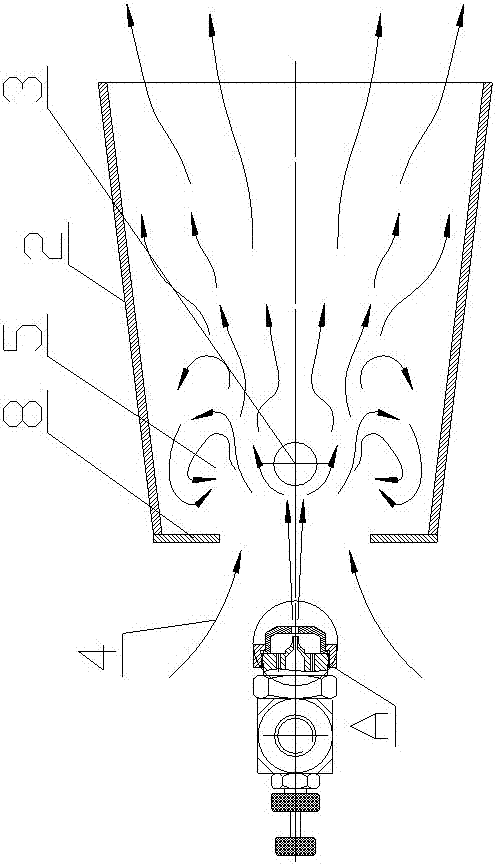

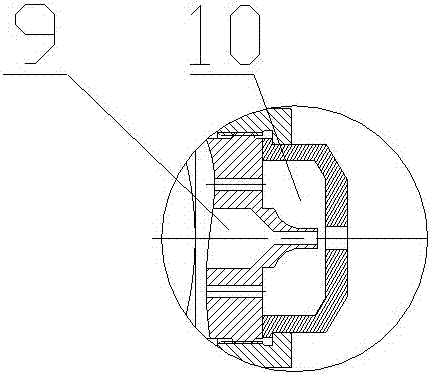

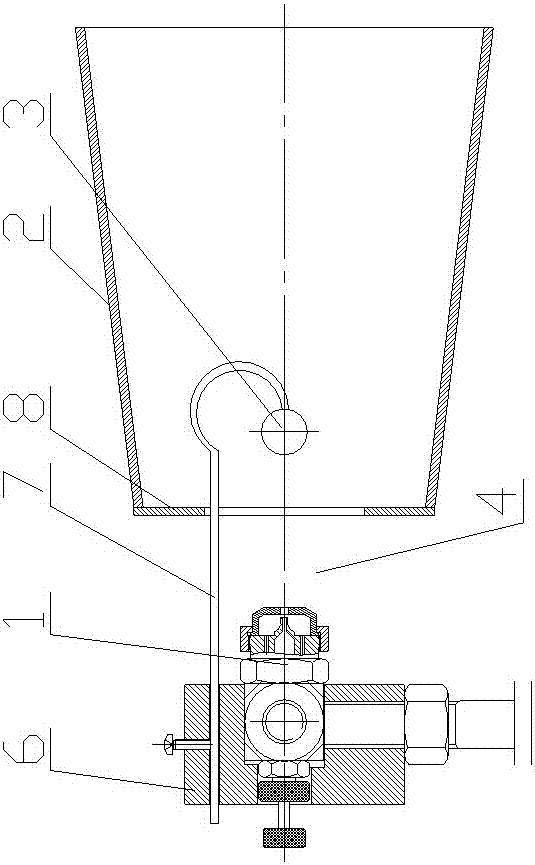

[0041] As shown in the figure, in the present invention, the atomizing nozzle, the shaped steady flow cylinder, the stopper, the chuck, the connector, the atomizing nozzle and the tubular steady flow cylinder are separated to form a secondary air inlet. Wherein, the stopper is located in the tubular steady flow cylinder, the atomized substance sprayed out by the atomizing nozzle is in a radial shape, and the stopper is located on the atomized substance spraying center line of the atomizing nozzle. The inlet of the atomizing nozzle is connected with combustible liquid and compressed air. The combustible liquid and compressed air are mixed once in the atomizing nozzle. On the nozzle, the stopper is connected to the collet through a connecting piece. Take the section of the tubular steady flow cylinder close to the atomizing nozzle as the proximal end, and take the section of the tubular steady flow cylinder far away from the atomizing nozzle as the far end. The proximal end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com