Direct-current submarine cable for flexible power transmission

A flexible power transmission and submarine cable technology, applied in power cables, power cables with shielding/conducting layers, cables, etc. Change the direction of power transmission, save cost, and reduce the effect of line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

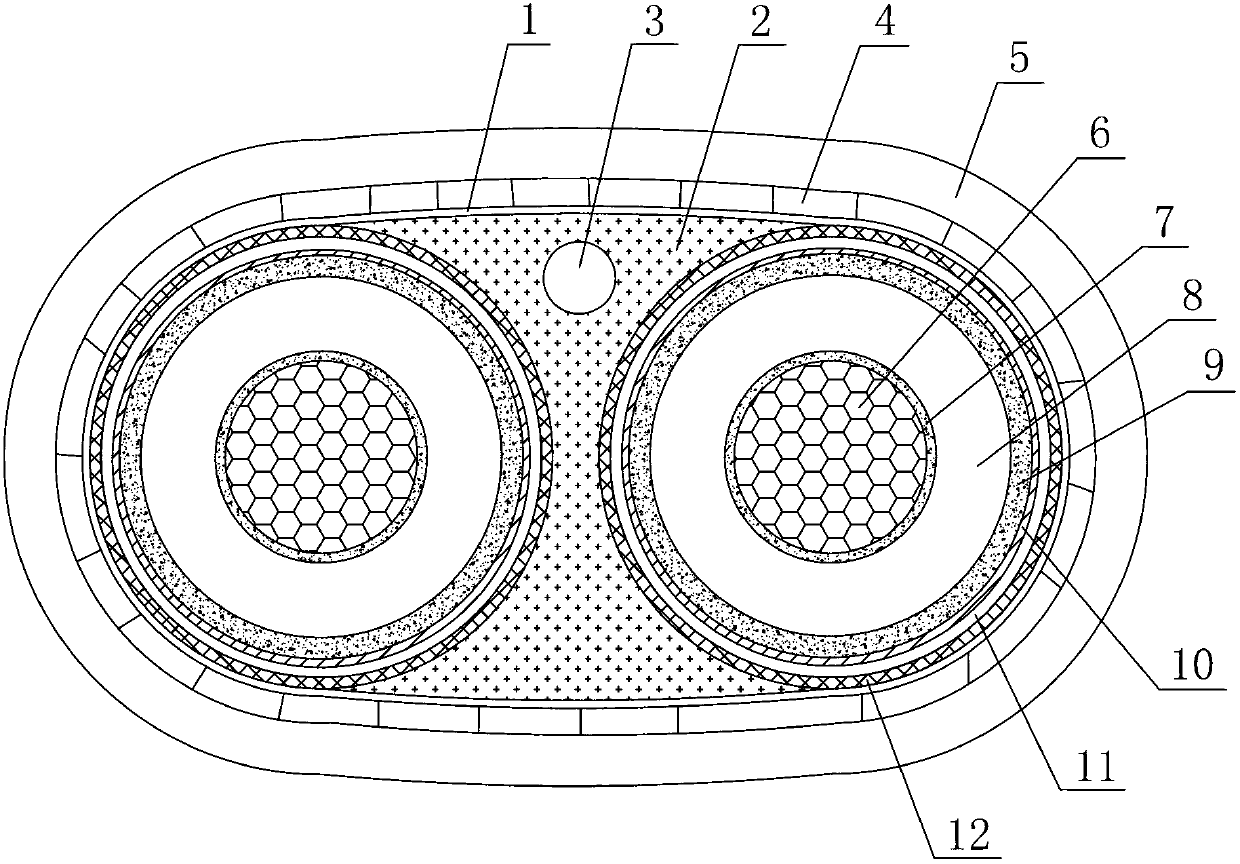

[0016] As shown in the figure, the DC submarine cable for flexible power transmission includes two DC units, the two DC units are wrapped with an inner liner 1, and the gap formed by the inner liner 1 and the DC unit is filled with a filling strip 2 and a The root light unit 3, the light unit 3 is located between the filling strips 2, a layer of flat armor layer 4 coated with asphalt is arranged outside the inner lining layer 1, the flat armor layer 4 is composed of zinc-magnesium-aluminum alloy flat steel wires, and the flat armor layer Layer 4 is wrapped with an outer layer 5. The DC unit includes a water-blocking conductor 6, an inner shielding layer 7, an insulating layer 8 and an outer shielding layer 9 arranged in sequence from the inside to the outside. The material of the insulating layer 8 is DC cross-linked polymer. Ethylene, the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com