Jack

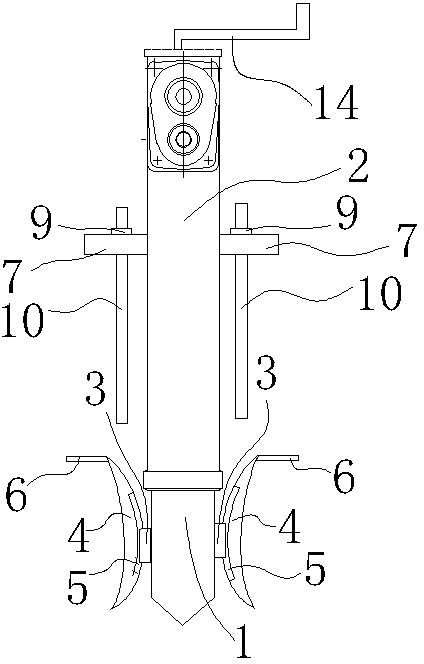

A technology of jacks and baffles, applied in the direction of lifting devices, etc., can solve the problems of inability to lift heavy objects, lateral displacement of jacks, and sinking of jacks, etc. The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

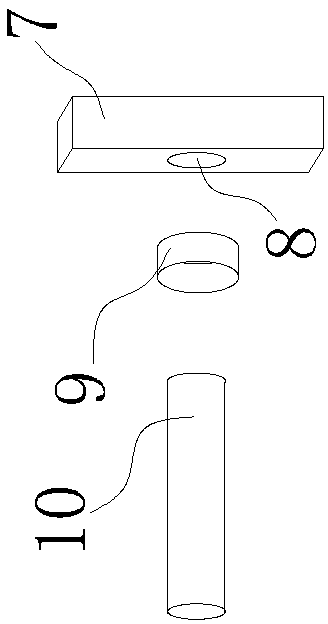

[0023] Embodiment 2: Compared with Embodiment 1, the difference lies in that the way the jack is fixed in the muddy ground is different, and the rest are the same.

[0024] see Figure 3~6 , the plane end of the conical head is provided with a No. 2 baffle 101, and the No. 2 baffle 101 increases the contact area between the jack and the mud, so that the jack is not easy to sink when stressed. The No. 2 baffle plate 101 is provided with a No. 2 through hole 103, and the No. 2 through hole 103 is evenly distributed on the No. 2 baffle plate 101, and the air under the No. 2 baffle plate 101 is evenly circulated, which is convenient for jacking up Get off the silt side. The diameter of the No. 2 through hole 103 is preferably greater than one centimeter, so that the air circulation under the No. 2 baffle plate 101 is more thorough, and it is more convenient for the jack to pull out from the mud surface.

[0025] Perpendicular to the No. 2 baffle 101, there are at least four No. ...

Embodiment 3

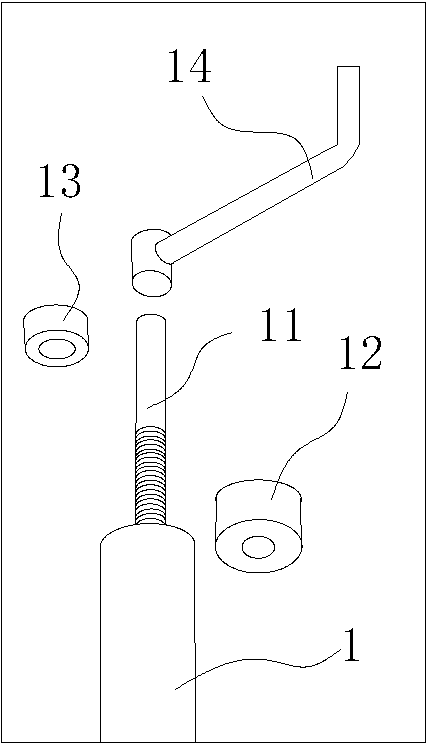

[0026] Embodiment 3: Compared with Embodiment 1, the difference lies in that the way the jack is fixed in the muddy ground is different, and the rest are the same.

[0027] see image 3 , Figure 7 with Figure 8 , the two sides of the connection position between the conical head and the inner cylinder 1 are hinged with two movable No. 4 baffles 201. The No. 4 baffles 201 are used to support the jack in the muddy ground. The movable No. 4 baffles The board 201 can facilitate the jack to pick up in the muddy ground. The end of the No. 4 baffle 201 contacting the ground is arc-shaped. When the jack just touched the ground, the arc-shaped end kept a certain gap between the No. 4 baffle 201 and the ground to prevent one end of the No. 4 baffle 201 from being inserted into the silt, thereby hindering the four No. baffle plate 201 turns upwards.

[0028] The No. 4 baffle plate 201 is provided with a No. 3 through hole 205, and the No. 3 through hole 205 is convenient for the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com