Scribing method for brittle material substrate

A brittle material substrate and scribing groove technology, which is used in stone processing equipment, fine working devices, glass manufacturing equipment, etc., can solve the problems of edge width limitation, inability to reduce beam width, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

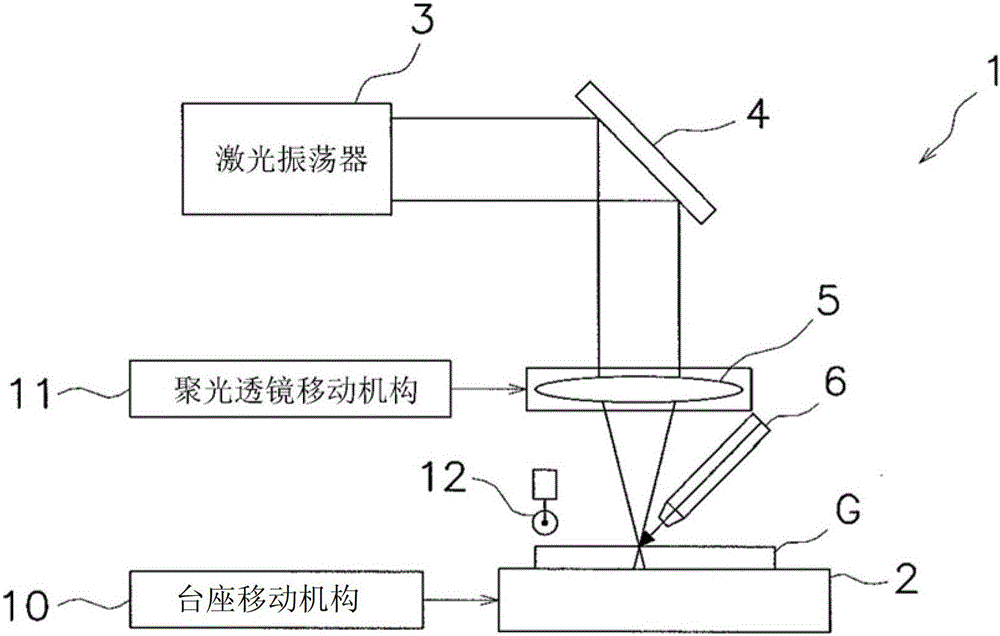

[0048]

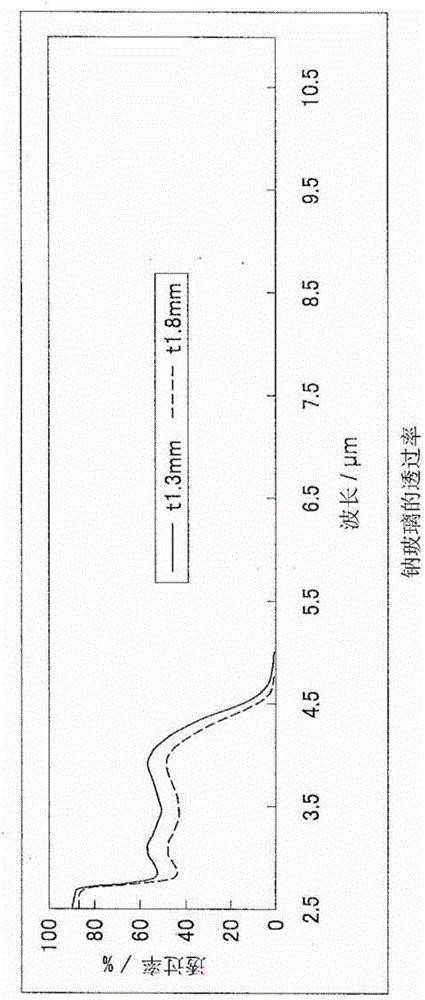

[0049] figure 2 The relationship between the wavelength and transmittance of laser light (Er fiber laser) irradiated on soda glass having various thicknesses is shown in . In addition, in Table 1, the transmittance and absorptivity of each board thickness are shown. In addition, the absorption rate is a calculated value.

[0050] Table 1 Transmittance and absorptivity of each plate thickness

[0051] Plate thickness / mm

Absorption rate (calculated value)

1.3

55%

45%

1.8

46%

54%

[0052] It can be clearly seen from these charts that in the wavelength range of 2.8 μm to 4.0 μm, for glass substrates with a thickness of 1.3mm (solid line) and 1.8mm (dashed line), the transmittances are 55% and 46%, respectively. The absorption rate is 45% and 54% respectively, and has a certain degree of absorption and permeability. For a substrate having such a thickness, the irradiated laser light is absorbed insi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com