Fluorocarbon paint for building sheet material

A technology for fluorocarbon coatings and building boards, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of high price of fluorocarbon coatings, less fluorocarbon coatings, and the coating effect needs to be further improved, etc. To achieve the effect of simple construction method, excellent weather resistance and low price

Inactive Publication Date: 2013-06-05

孙月静

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, fluorocarbon coatings on the market are mainly used in the coating of concrete building exterior walls, metal coils, aluminum profiles, aluminum-plastic panels, plastic steel profiles, ceramic tiles, road signs, ship surfaces, etc., but fluorocarbon coatings applied to calcium carbonate plates At the same time, fluorocarbon coatings also have the disadvantage of high price, and the coating effect needs to be further improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] Embodiment 1 A kind of fluorocarbon coating for building panels

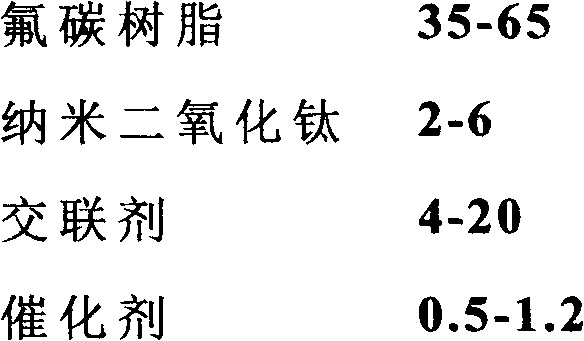

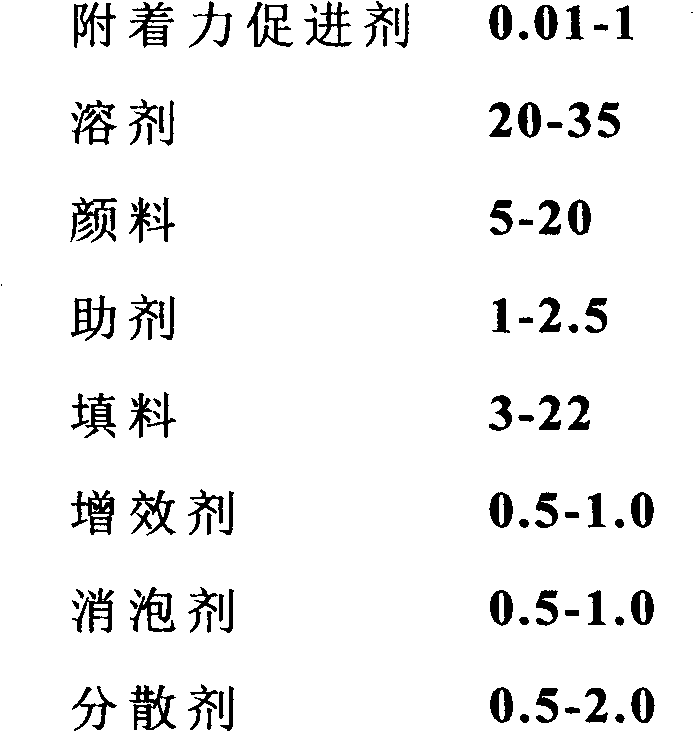

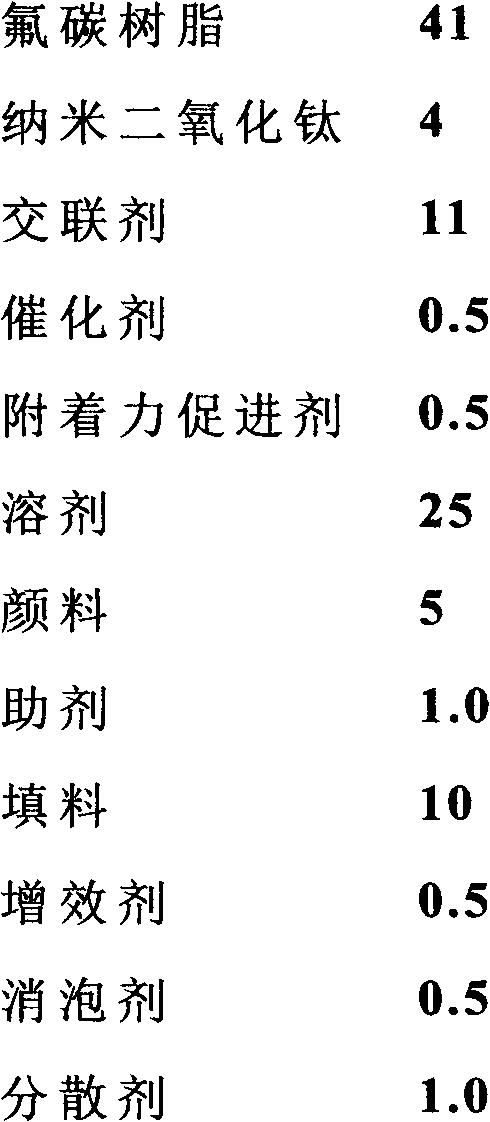

[0031] 1.1 Take the following raw materials according to the formula:

[0032]

[0033] 1.2 Mix the above-mentioned raw materials uniformly according to the conventional method under stirring conditions, and make them completely dissolve, stir at a low speed (500 rpm) for about 30 minutes, and prepare the fluorocarbon coating of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of building decoration spraying and discloses fluorocarbon paint for a building sheet material and a preparation method thereof. The fluorocarbon paint has high color fidelity, selection diversity, good wear resistance, excellent weatherability, good corrosion resistance, ultraviolet resistance, and long service life, can be dried at a normal temperature, can be used simply, is suitable for a plurality of base materials and has a low price.

Description

technical field [0001] The invention belongs to the field of architectural decoration, and relates to a fluorocarbon paint for building boards, in particular to a fluorocarbon paint for spraying calcium silicate boards. Background technique [0002] With the development of the economy and the improvement of people's living standards, people's aesthetic view of the living room is constantly improving, and the decoration of living room walls, floors, furniture, etc. is increasingly emphasizing decorative effects and environmental protection requirements. [0003] Known as the most high-grade fluorocarbon coating in the decoration industry, it is widely used for its wide color selection, excellent durability, long service life and practicability of various substrates. Ordinary coatings applied outdoors have a longest service life of 5 years, while fluorocarbon coatings have a service life of up to 20 years. At the same time, the fluorocarbon coatings used for exterior walls ca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D127/12C09D5/14C09D5/08C09D7/12

Inventor 孙月静

Owner 孙月静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com