Undersea suction anchor

A suction anchor and anchor ring technology, applied in anchor points, water conservancy projects, ship parts, etc., can solve the problem that the horizontal bearing capacity and overall stability cannot be effectively improved, the bearing capacity and overall stability are not much improved, and the seabed soil Erosion does not have much effect and other problems, to achieve the effect of preventing seabed erosion, increasing overall stability, and reducing the difficulty of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

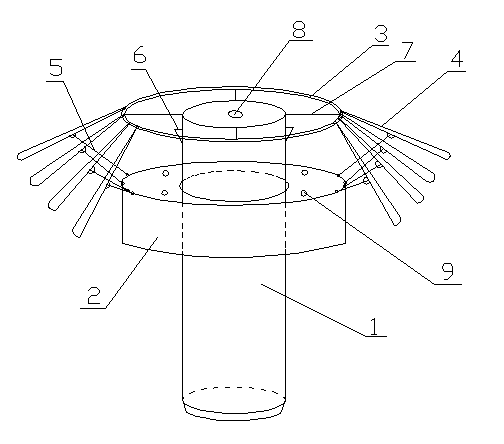

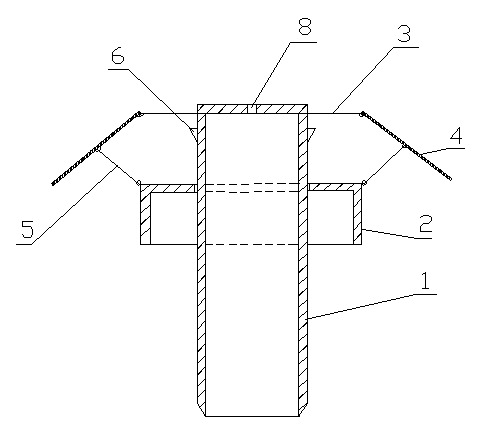

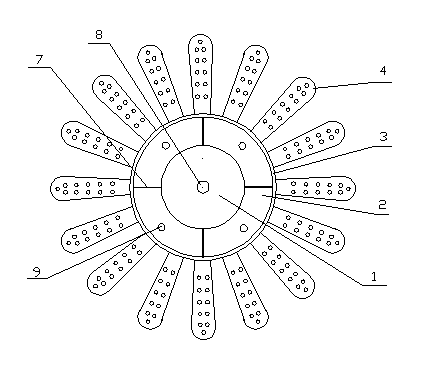

[0024] See attached Figure 1-Figure 3 , an embodiment of a submarine umbrella suction anchor of the present invention, comprising a main cylinder 1 with a closed top surface and an open lower end, and a main cylinder drainage hole 8 is arranged on the top surface of the main cylinder 1 . A tube skirt 2 is looped outside the main tube 2, and the tube skirt 2 includes a horizontal top surface and a cylindrical side wall, and a tube skirt drainage hole 9 is arranged on the horizontal top surface of the tube skirt. Two telescopic hooks 6 are symmetrically arranged on the cylindrical side wall on the upper part of the main cylinder 1 to position the skirt on the upper part of the main cylinder. An anchor ring 3 concentric with the main cylinder 1 is arranged at the upper end of the main cylinder 1, and anchor branches 4 are evenly arranged on the anchor ring 3, one end of the anchor branch 4 is hinged with the anchor ring 3, and the other end is connected to the skirt through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com