Combination floating type brake pad

A brake pad, floating technology, applied in the direction of brake type, brake components, mechanical equipment, etc., can solve the problems of support failure, broken pawl damage, etc., to improve support performance and elasticity, ensure working life, and effectively The effect of increasing the braking area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

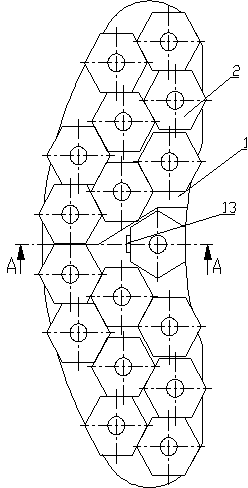

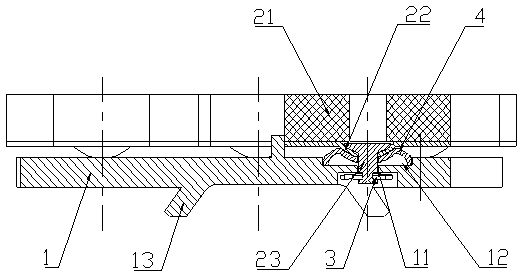

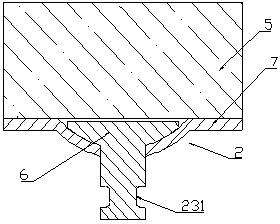

[0033] figure 1 , figure 2 It is a combined floating brake pad of the present invention, which includes a combined back plate formed by splicing and connecting two back plates 1; several friction blocks 2 arranged on the back plate 1; The elastic support piece 4 between the friction block 2 and the back plate 1 , and the clip spring 3 that connects the friction block 2 to the first back plate 1 in a floating manner.

[0034] Wherein, in order to arrange the friction blocks 2 arranged on the backboard 1 tightly and utilize the space of the backboard 1 as much as possible, the combined backboard consists of two asymmetric backboards 1 Spliced together, wherein the number of the positioning holes 11 on one of the backboards 1 is greater than the number of the positioning holes 11 on the other backboard 1, in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com