Checking circuit for energy storage device terminal voltage

An energy storage circuit and device end technology, which is applied in the field of inspection circuits for the terminal voltage of energy storage devices, can solve the problems of long switching action time, complex production process, cumbersome calibration process, etc., and achieves fast channel switching speed, increased service life, Simple effect of peripheral circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

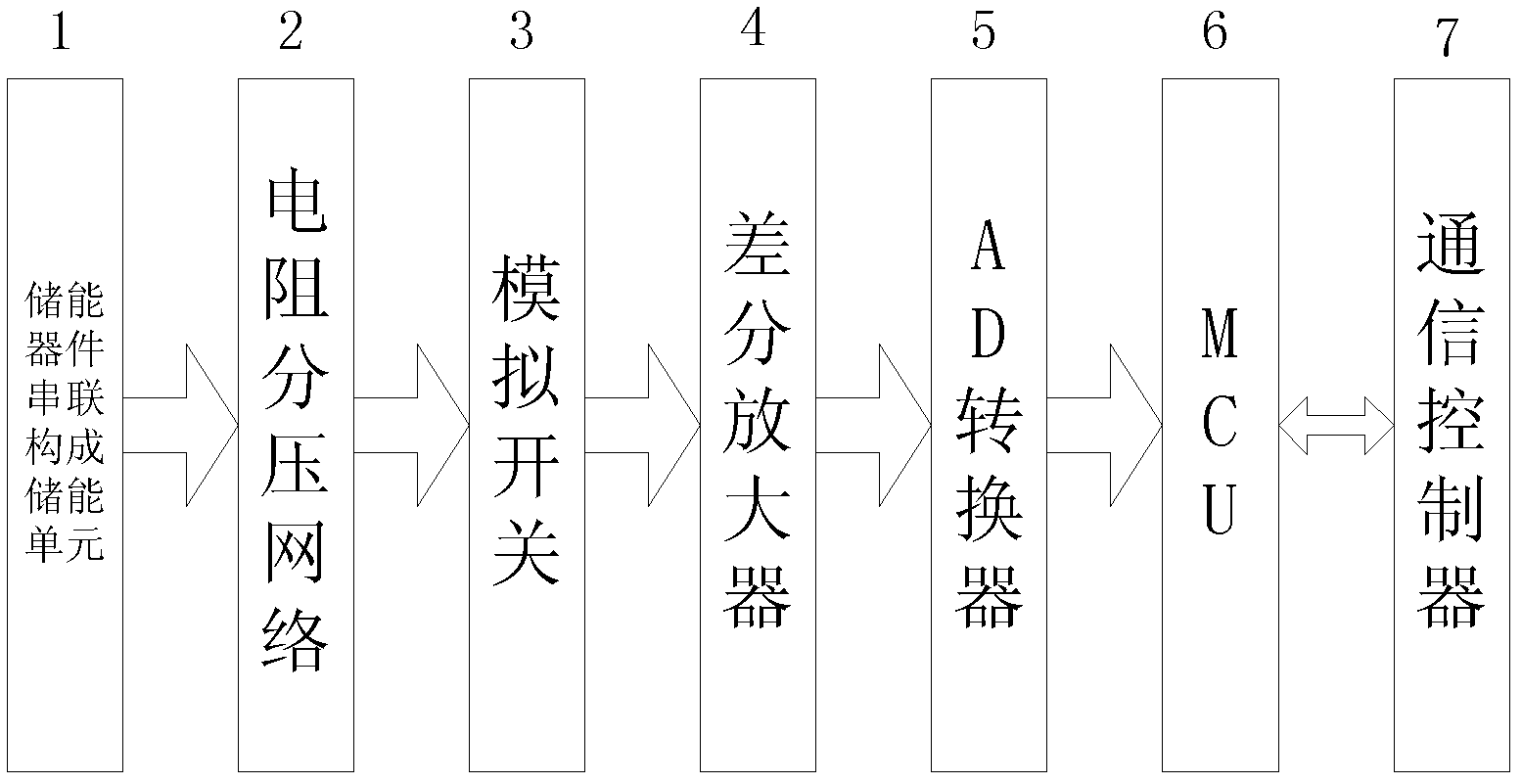

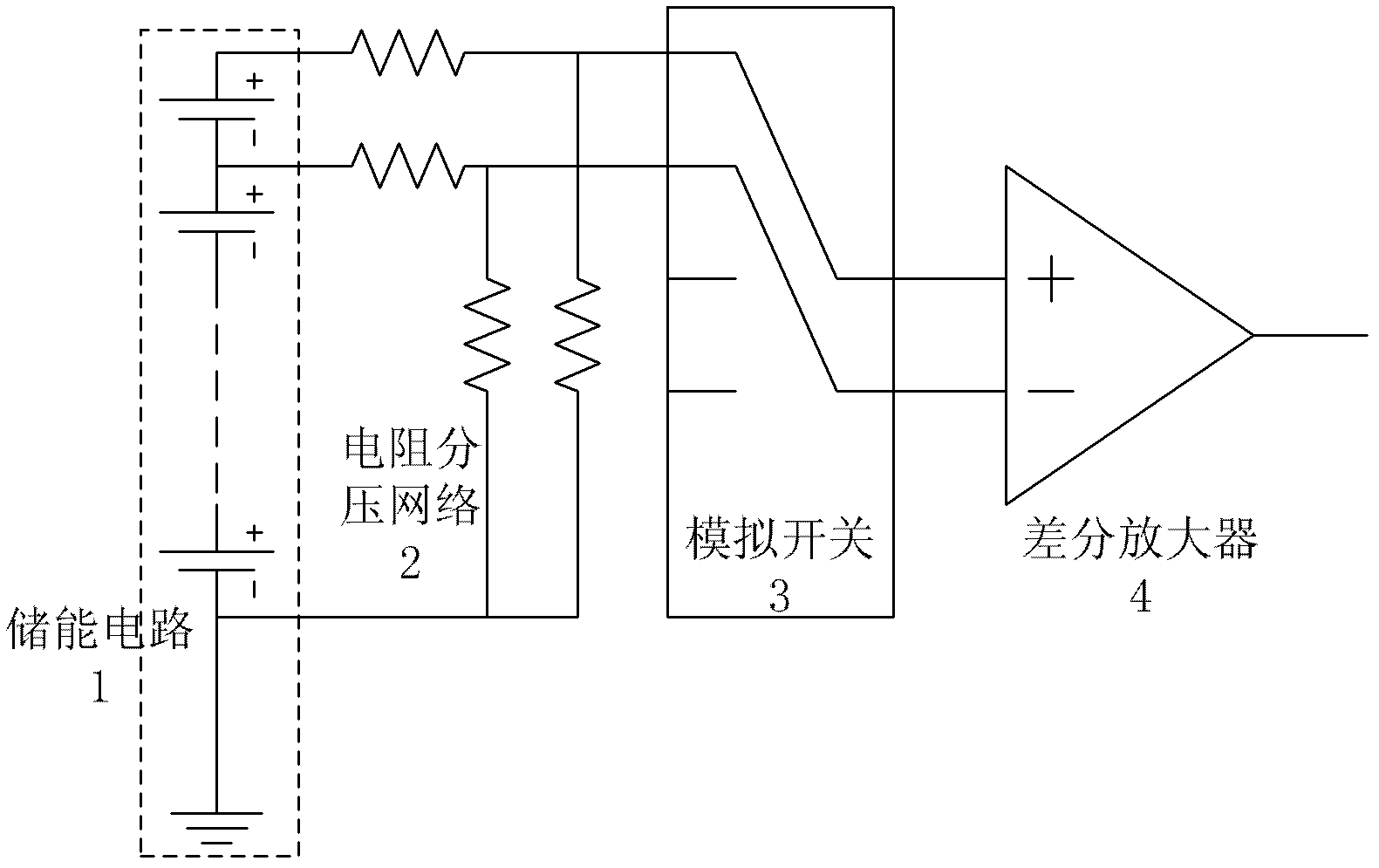

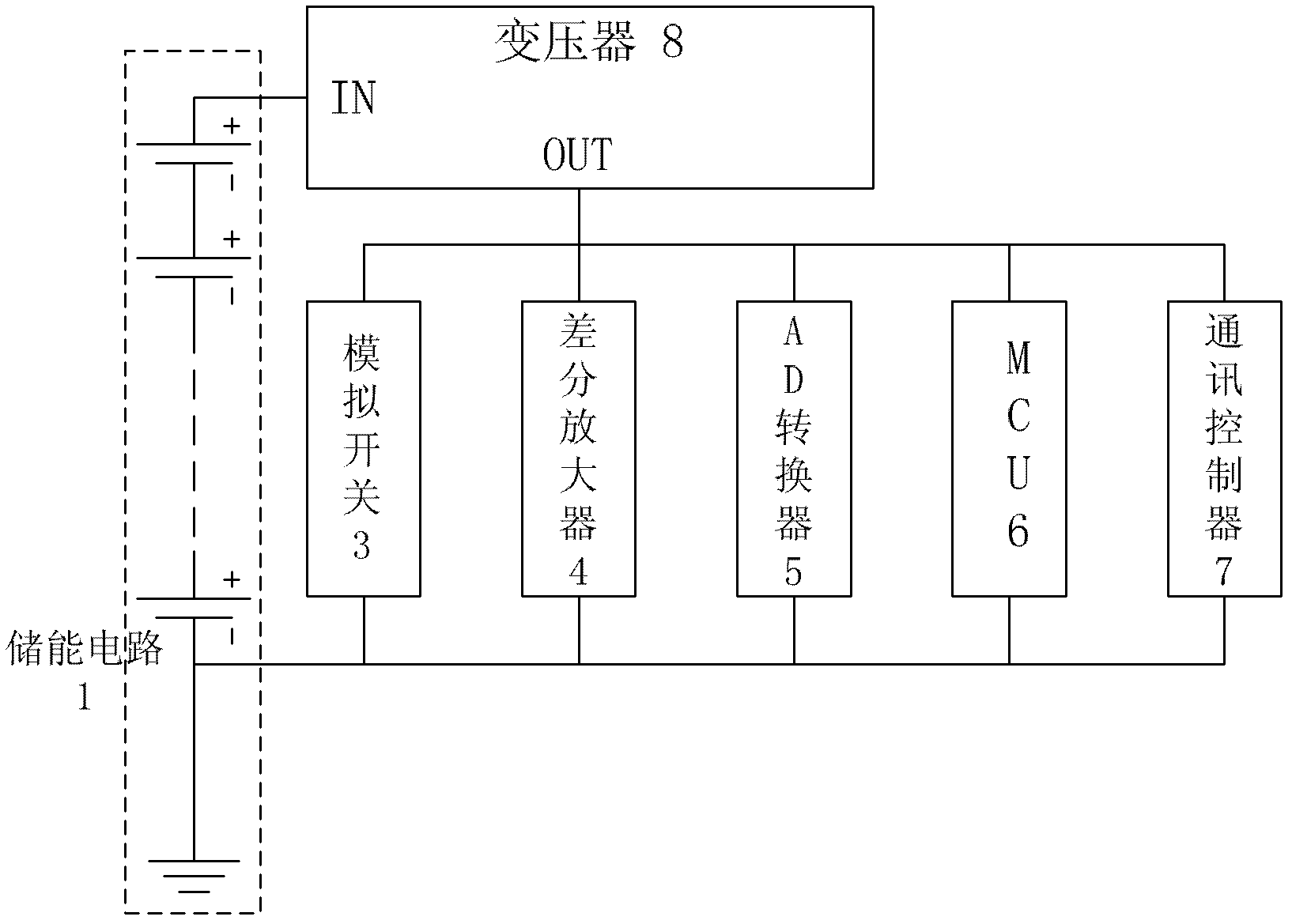

[0022] Such as figure 1 As shown, a patrol circuit for the terminal voltage of an energy storage device includes a resistor divider network 2 , an analog switch 3 , a differential amplifier 4 , an A / D converter 5 , and a microcontroller 6 . The resistance voltage divider network 2 is connected to the node of the energy storage circuit 1 composed of energy storage devices in series, and the voltage of the node is reduced proportionally to the acceptable voltage range of the analog switch 3 by means of resistance voltage division, and the analog switch 3 is connected to the resistance voltage divider network The output end of 2 and the input end of differential amplifier 4 are used for switching the node acquisition channel of energy storage circuit 1, and its specific structure is as follows figure 2 shown.

[0023] The differential amplifier 4 inputs the voltages of the two nodes through the analog switch 3, amplifies the voltage difference between the two nodes to the volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com