Forming method of metal oxide semiconductor (MOS) device and MOS device formed through method

A technology of MOS devices and epitaxy, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as leakage, and achieve the effect of less leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

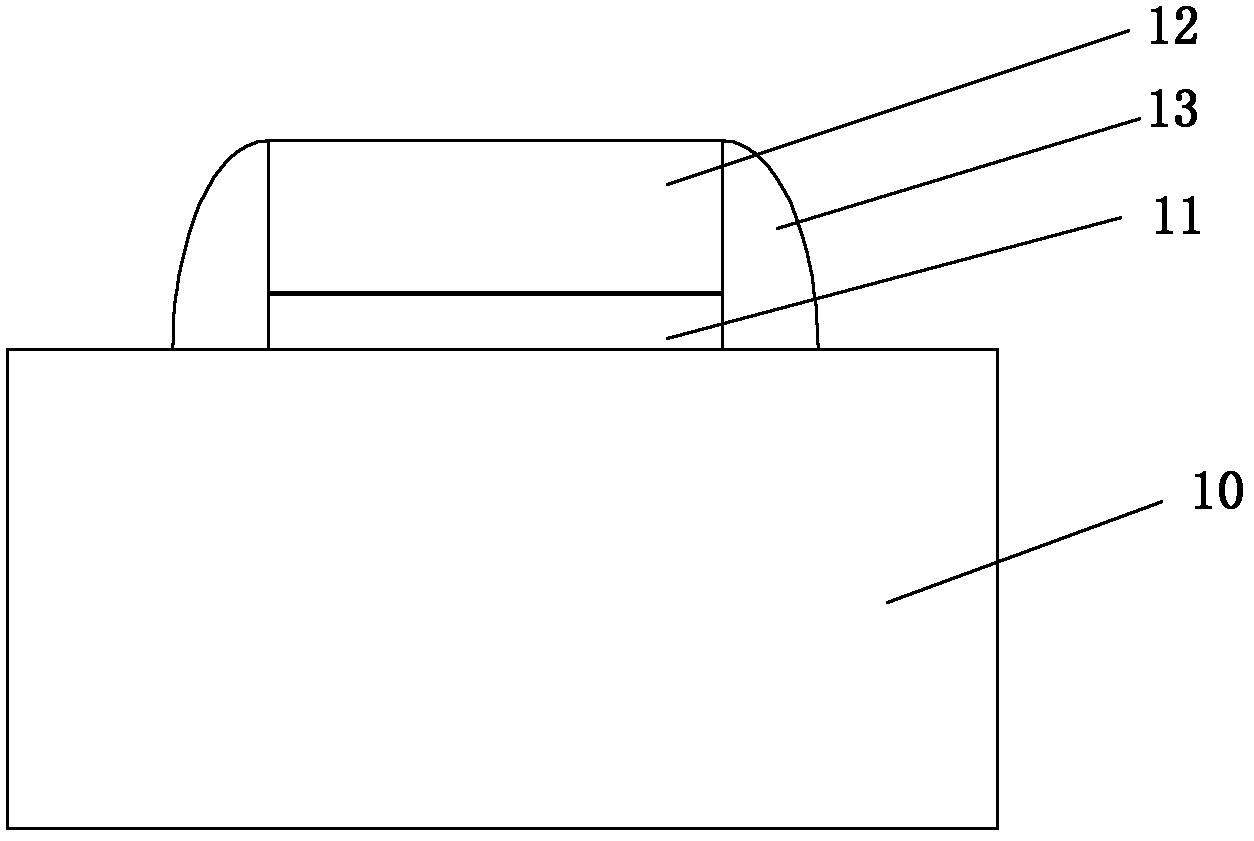

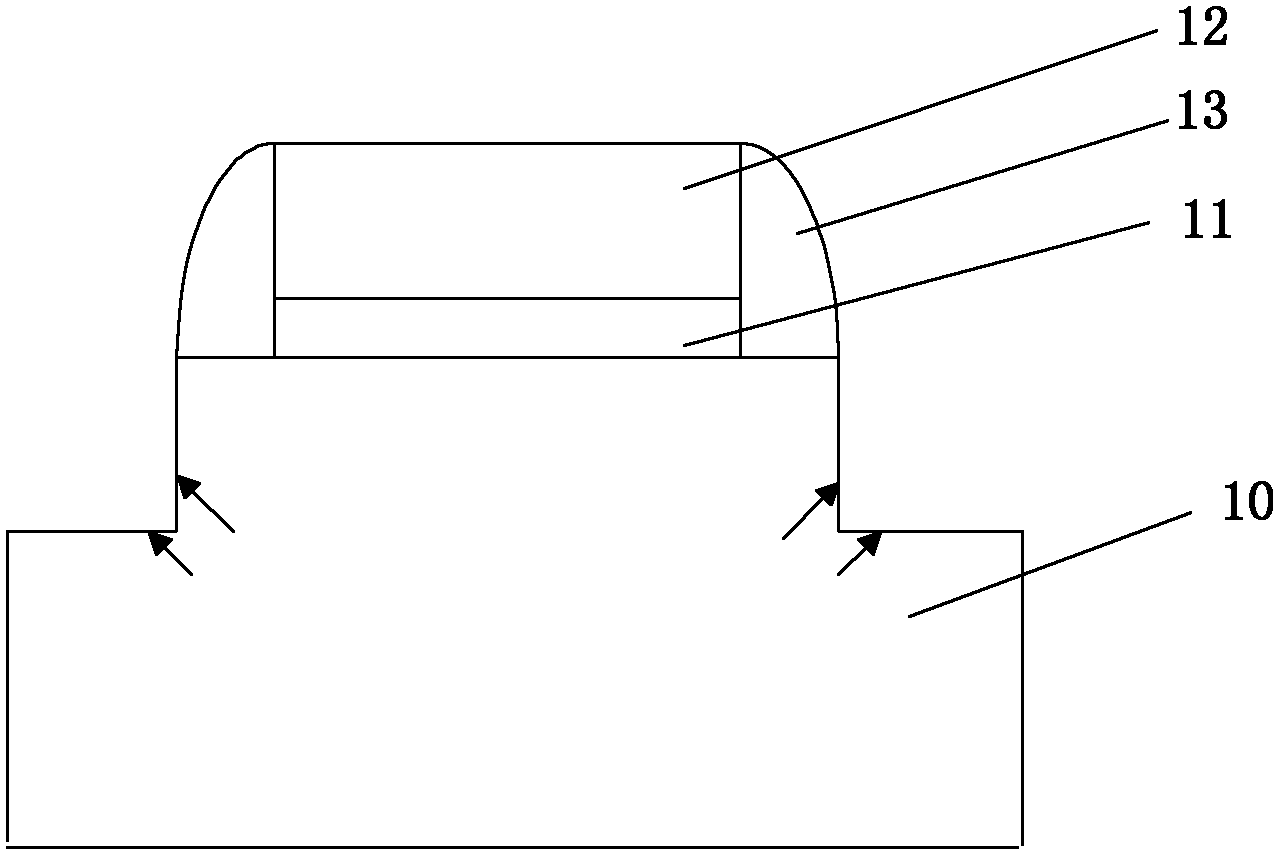

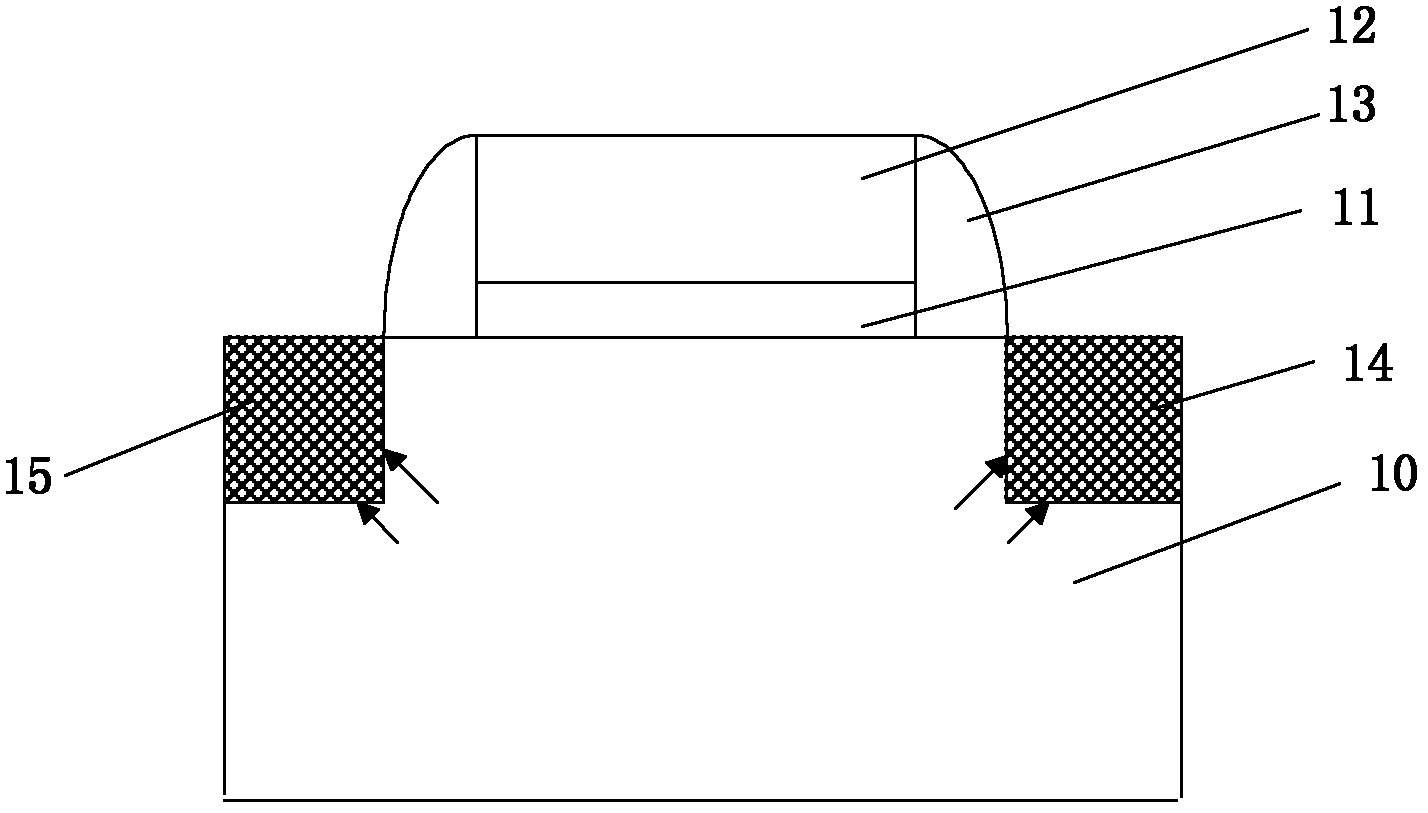

[0045] In the existing MOS structure, when forming the silicon-germanium source and drain, the semiconductor substrate is first etched by a self-alignment method, which will form large defects in the semiconductor substrate. In the MOS structure with this defect, the source region and the drain region will leak electricity into the substrate during use. In response to this problem, the inventors of the present invention proposed to first form an epitaxial layer in the channel region by epitaxial method, which is exactly the same material and lattice structure as the semiconductor substrate, and then use isotropic etching to etch the epitaxial layer. The epitaxial layer avoids the use of the self-alignment method used in the prior art to etch the semiconductor substrate, thus reducing the damage in the semiconductor substrate, that is, the intersection of the source region and the drain region with the semiconductor substrate, and achieving For the purpose of reducing defects, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com