Organic light-emitting diodes (LEDs) and organic LED displayer composed of the same

A technology of light-emitting diodes and displays, applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., which can solve problems such as difficult alignment, high cost, and difficult fabrication of metal masks 17, and achieve the effect of avoiding voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the above-mentioned and other objects, features, and advantages of the present invention more comprehensible, the preferred embodiments are listed below, together with the accompanying drawings, and are described in detail as follows:

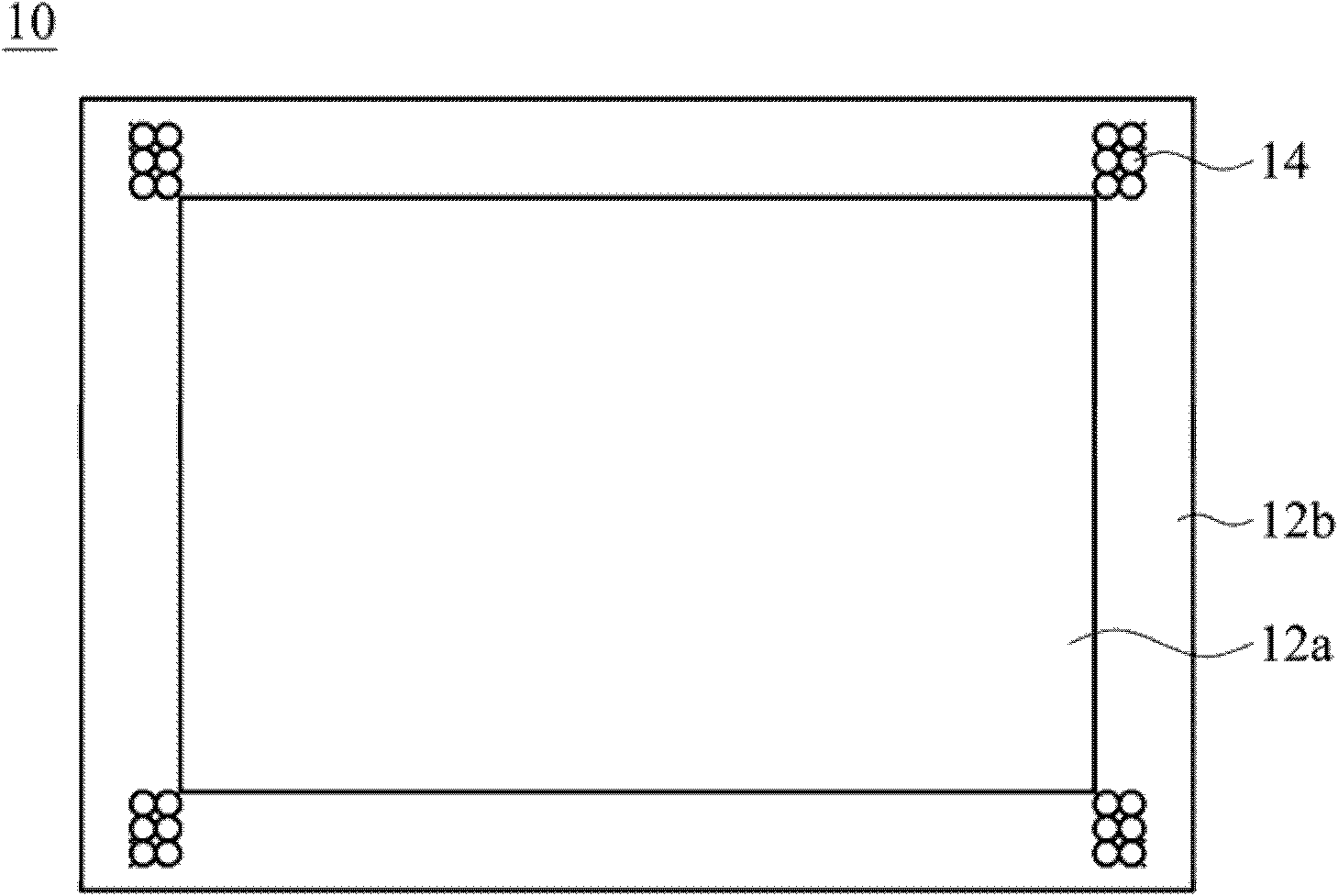

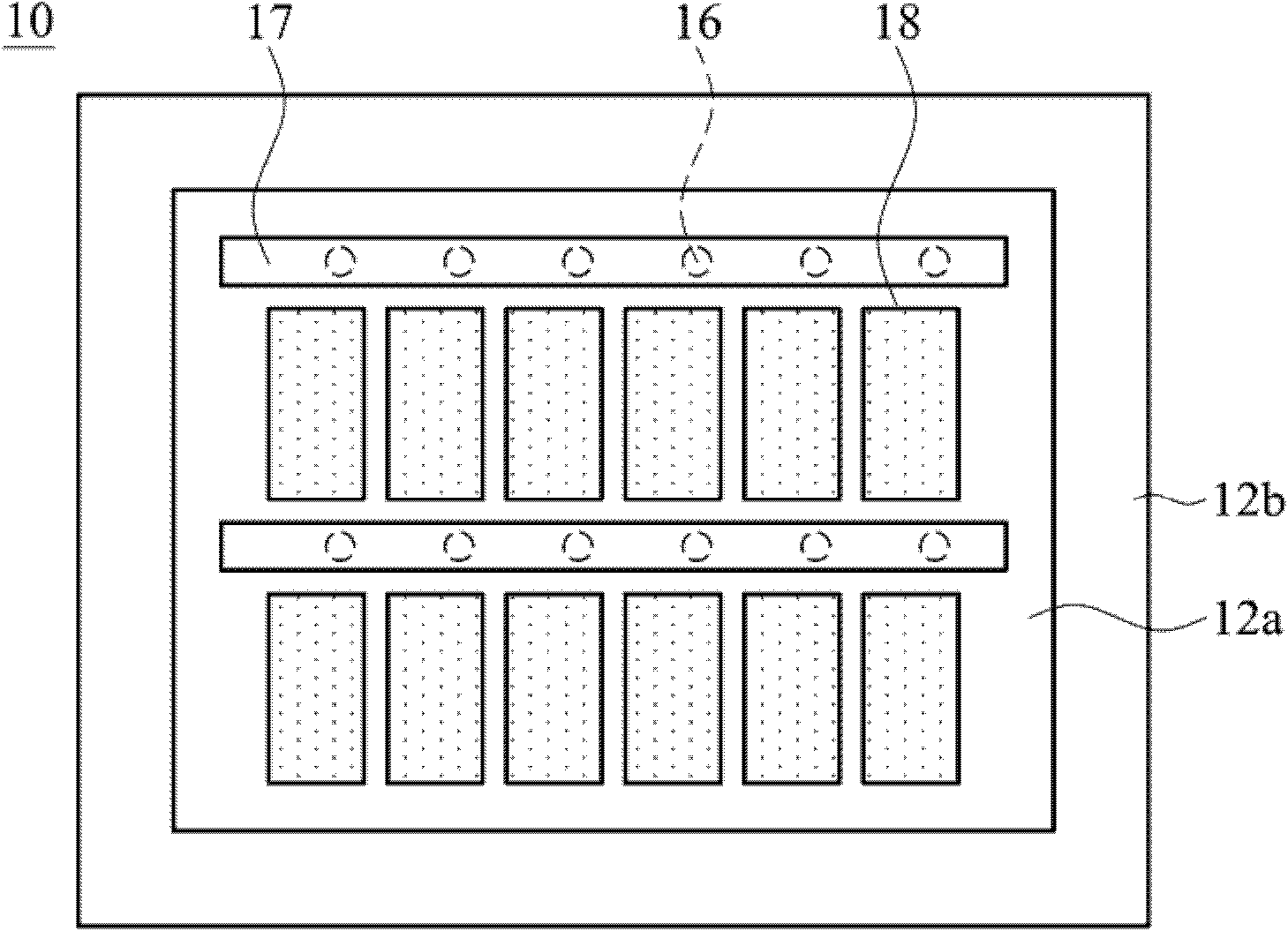

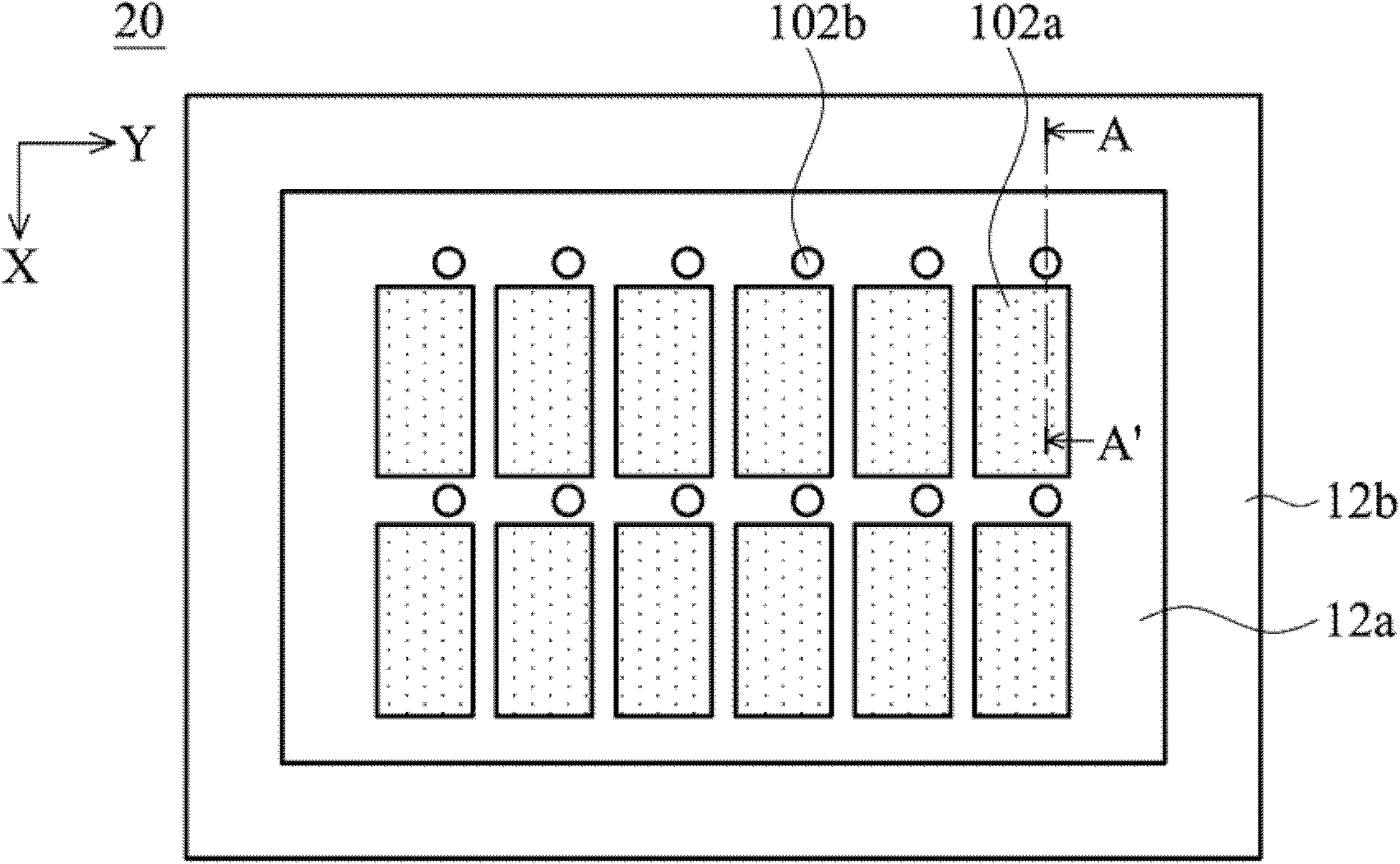

[0063] figure 2 It is a top view of the top emission (top emission) organic light emitting diode 20 of the present invention, Figure 3A , Figure 3B , Figure 3C to Figure 3D for a series of figure 2 The cross-sectional view of line AA' in the middle shows the fabrication method of the top emission (top emission) organic light emitting diode of the present invention. First, see Figure 3A , providing a substrate 101 . In the passive array organic light emitting diode display, the material of the substrate 101 is a common glass substrate, and may also be a plastic substrate in another embodiment. In an active matrix organic light emitting diode display, the substrate 101 is a thin film transistor (TFT) substrate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com