Manufacturing method and manufacturing apparatus for electrical device with film covering

A technology for electrical devices and thin-film packaging, which is applied in the manufacture of capacitors, electrical components, secondary batteries, etc., and can solve problems such as low ion conduction characteristics, unevenness, and reduced electrical characteristics of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the description of the drawings, the same reference numerals are assigned to the same elements, and overlapping descriptions are omitted. In addition, for convenience of description, the dimensional ratios in the drawings are exaggerated and may differ from actual ratios.

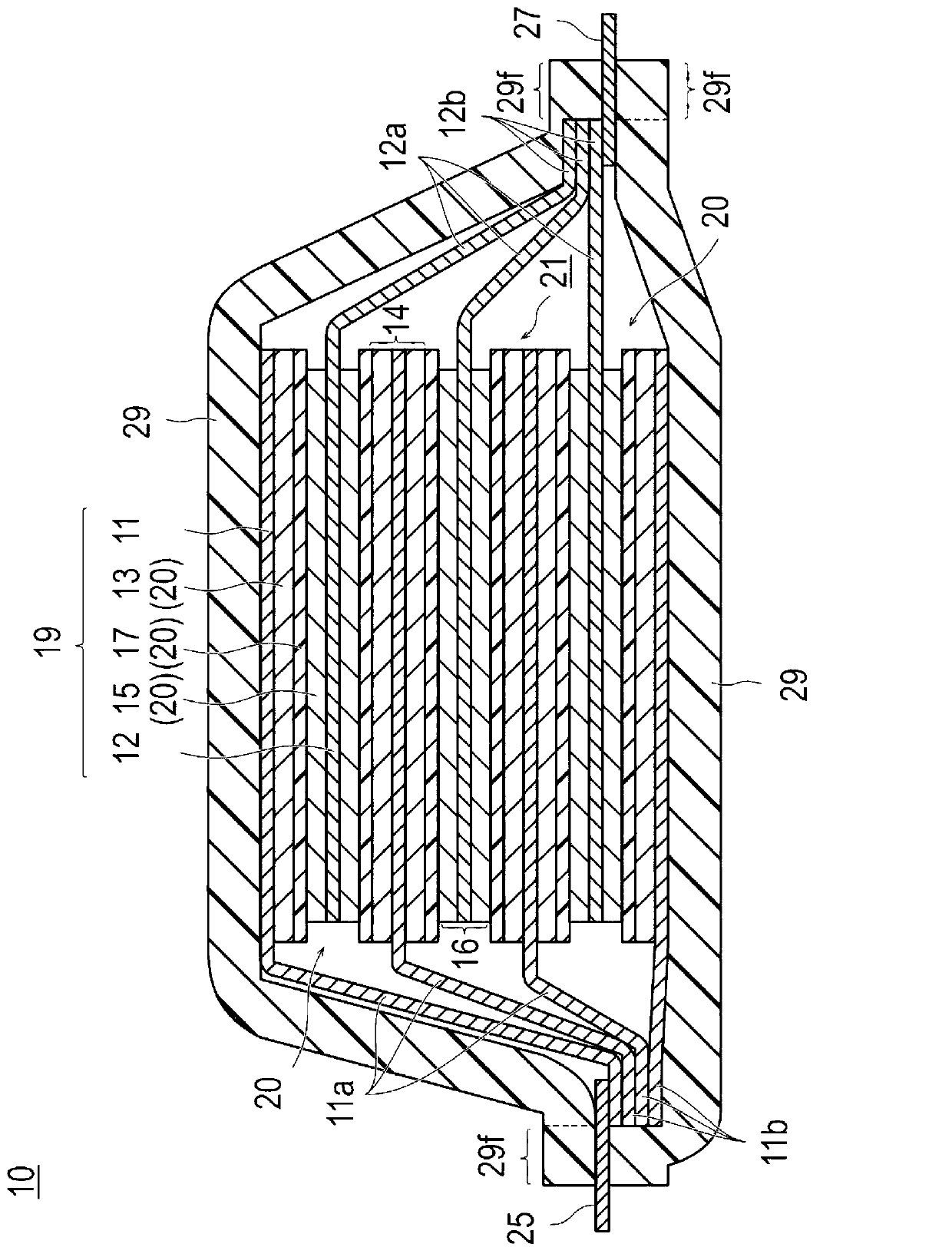

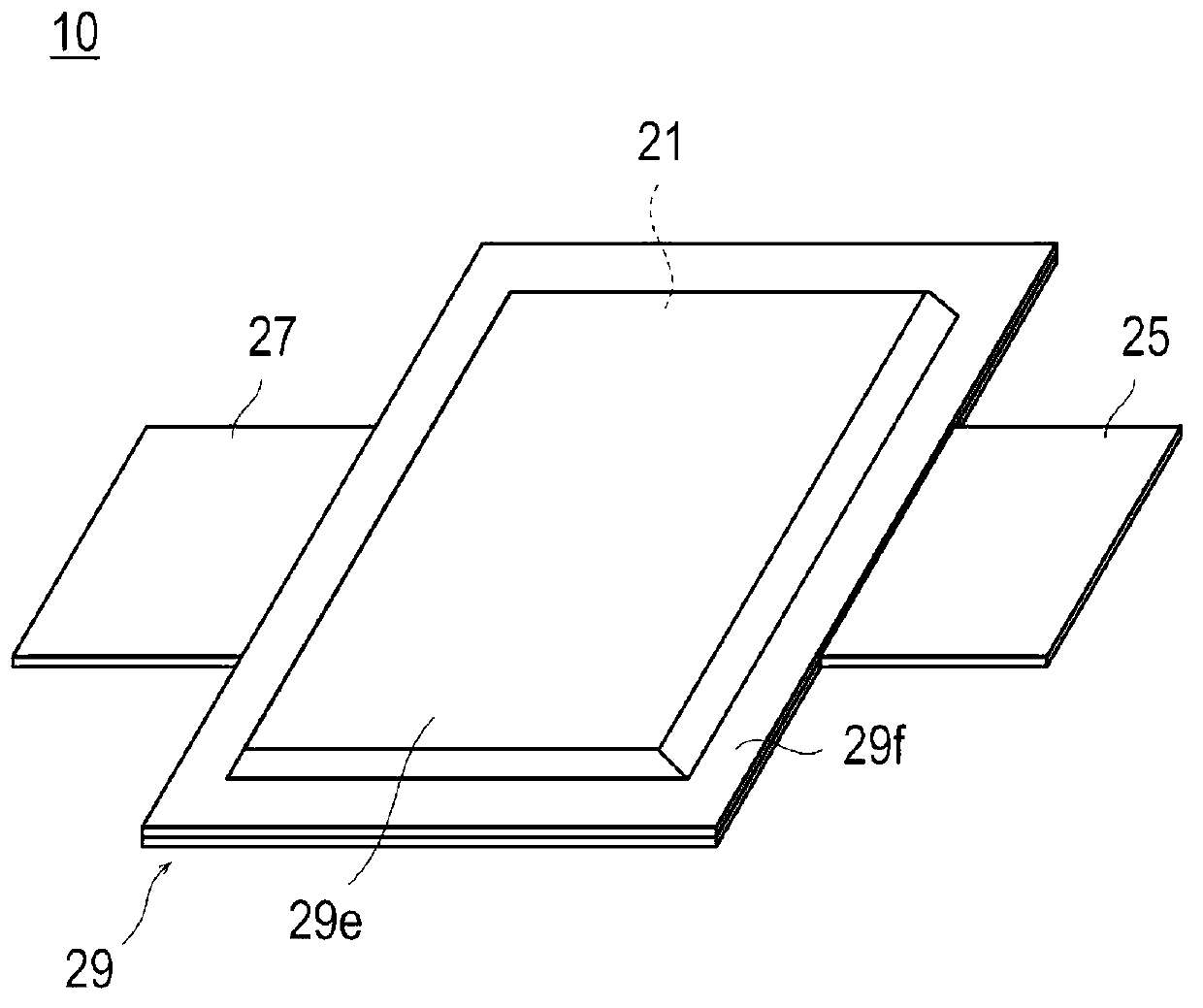

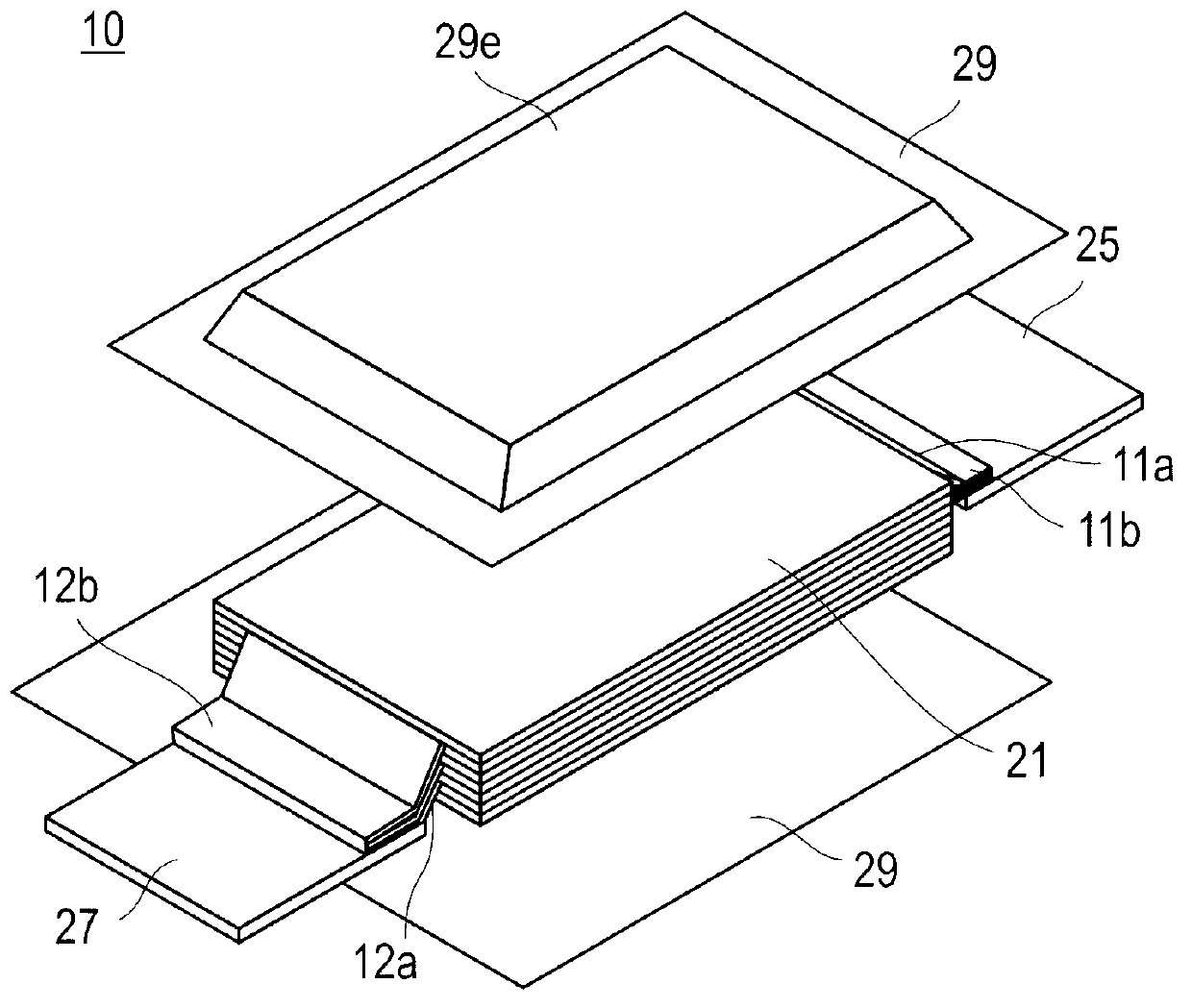

[0032] figure 1 It is a cross-sectional view schematically showing the structure of the film-sealed battery of the first embodiment. 2 is a perspective view schematically showing the film-encapsulated battery of the first embodiment, FIG. 2( a ) is a completed perspective view of the film-encapsulated battery, and FIG. 2( b ) schematically shows the first An exploded perspective view of the film-encapsulated battery according to the embodiment when it is disassembled into the state of each constituent element.

[0033] Thin film encapsulated battery

[0034] The outline of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com