Process for producing dried food eaten after hot-water cooking or hot-water reconstitution, and dried noodle

A technology for drying food and a manufacturing method, which is applied in the directions of food preparation, food preservation, and application, and achieves the effects of good separation, promotion of heat conduction, and improved separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

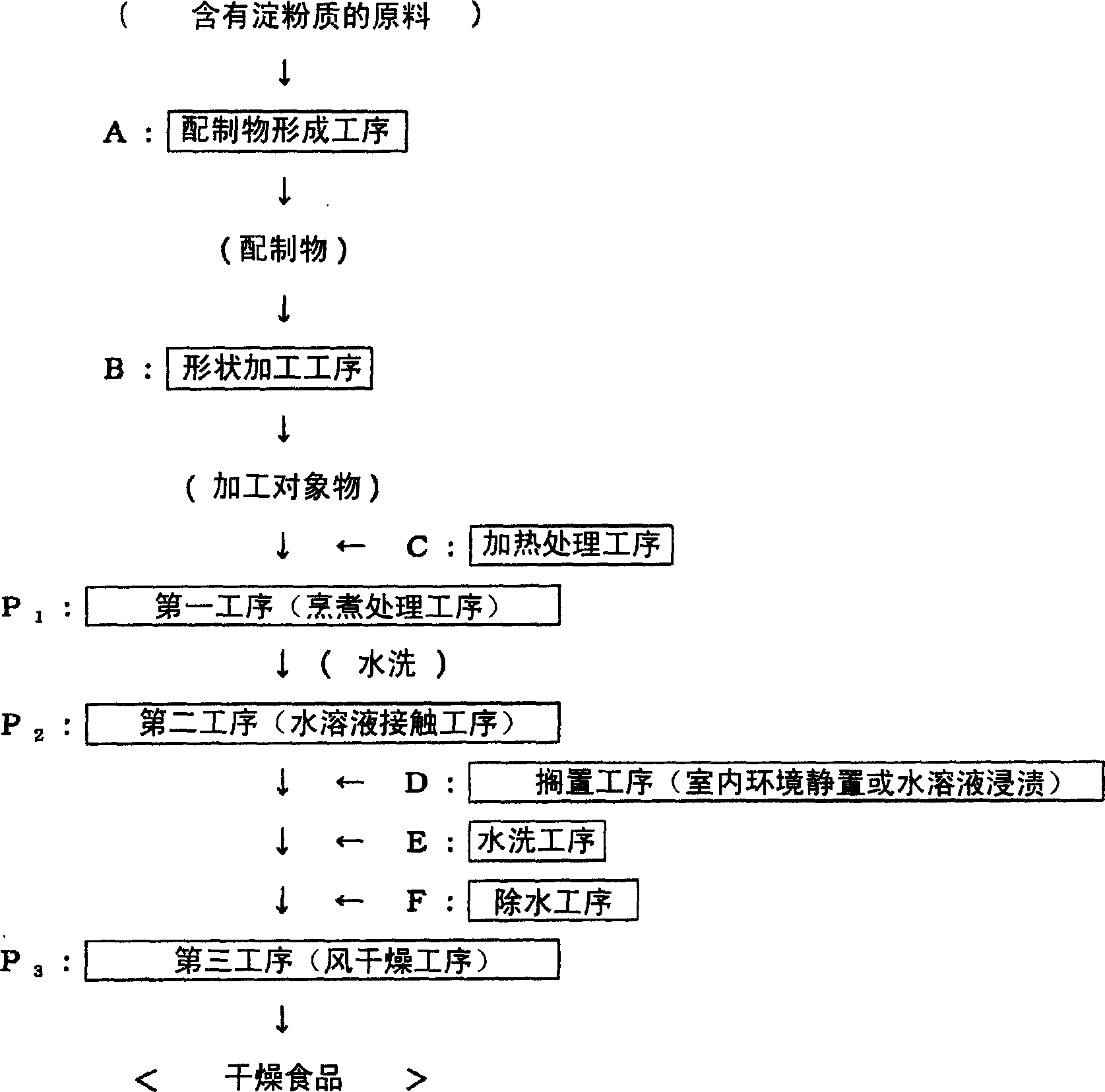

Method used

Image

Examples

Embodiment

[0148]

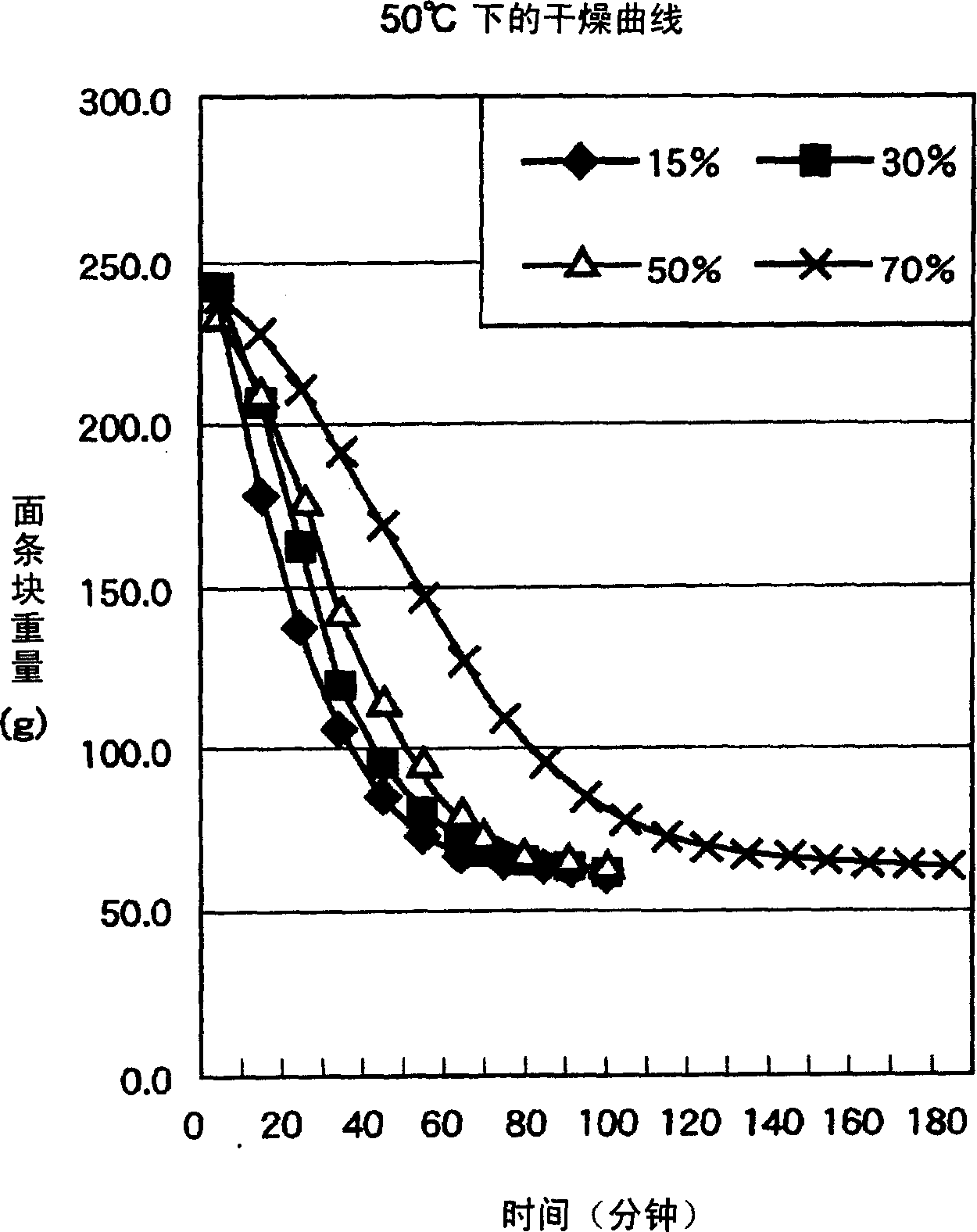

[0149] The purpose of this verification test is to verify the influence of the cooking treatment time in the first process on the final product, so as to select a suitable cooking time.

[0150] In this test, 3 kg of quasi-strong wheat flour was used as 100 parts by weight, mixed with 1 part by weight of salt, 1 part by weight of water-sensitive powder, 0.05 parts by weight of pigment, and 35 parts by weight of water, and rolled to form noodle strips. The obtained noodle strips were shaped by blades No. 20 (noodle thickness 1.25 mm), No. 16 (noodle thickness 1.15 mm), and No. 16 thick noodles (noodle thickness 1.40 mm) to obtain raw noodle strands as objects to be processed.

[0151] The object to be processed is subjected to steam heat treatment at 100°C for 3 minutes (heat treatment step), and in hot water at about 100°C, the first step ( cooking treatment). Immediately after that, make it contact with cold water, then take appropriate amount, and leave it for 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com