Glass fiber reinforced polyvinyl chloride composite material production system and method

A composite material and polyvinyl chloride technology, applied in the field of inorganic non-metallic materials, can solve the problems of poor mechanical properties, poor film-forming properties, and poor mechanical properties of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

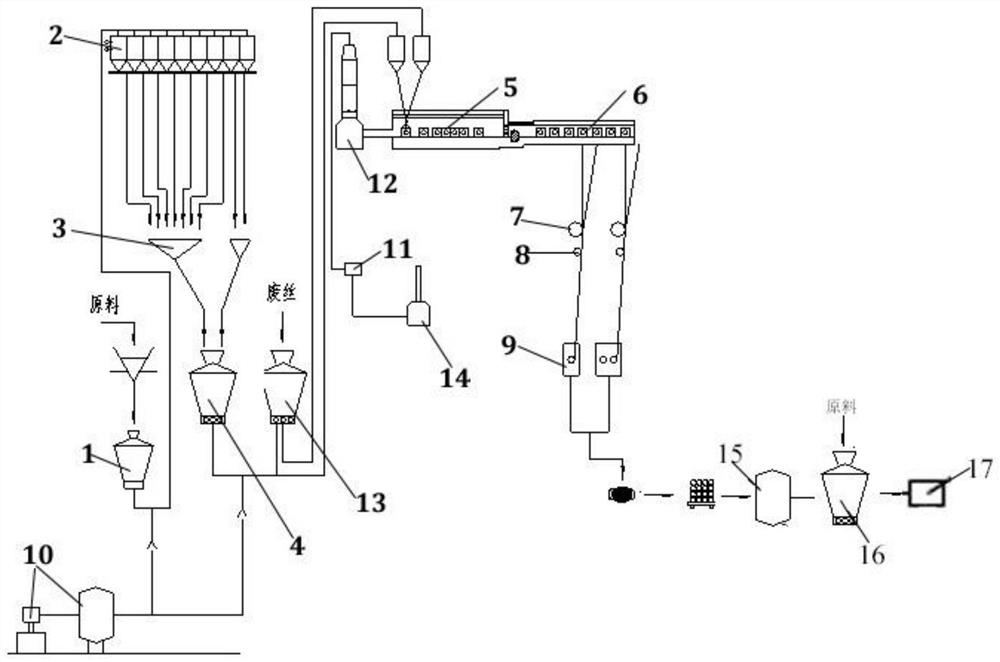

[0043] A glass fiber reinforced polyvinyl chloride composite material production system, see figure 1 , including: mixing device, heating device, tank kiln wire drawing device, soaking wire collecting device and composite material mixing and extrusion device;

[0044] The mixing device includes a raw material tank 1, a silo 2, a weighing device 3 and a mixing conveying tank 4. The raw material in the raw material tank 1 is conveyed to the silo 2 by pneumatic force, and the raw material in the silo 2 is weighed by the weighing device 3 and then piped Transport to the mixing transport tank 4, and use the air force to mix the raw materials evenly, and then transport them to the pool kiln wire drawing device through pulse air force;

[0045] The tank kiln wire drawing device includes a unit kiln 5 and an H-shaped passage 6 arranged at the end of the unit kiln 5. The raw material is melted into glass liquid in the unit kiln 5, and then flows to the H-shaped passage 6. The platinum ...

Embodiment 2-8

[0064] The contents of each substance are shown in Table 1 and the data in Examples 2-8 in Table 2 respectively, and the rest of the conditions are the same as in Example 1.

[0065] In order to further illustrate the beneficial effects of the present application, due to limited space, only Example 3 is used as an example to construct a comparative example as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com