Cathode for electrolysis cells

An electrolytic cell and cathode technology, applied in the field of cathodes for electrolytic cells, can solve the problems of irreconcilable requirements, high production costs, inability to use high-quality materials, etc., and achieve the effects of high-level cooling and large intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

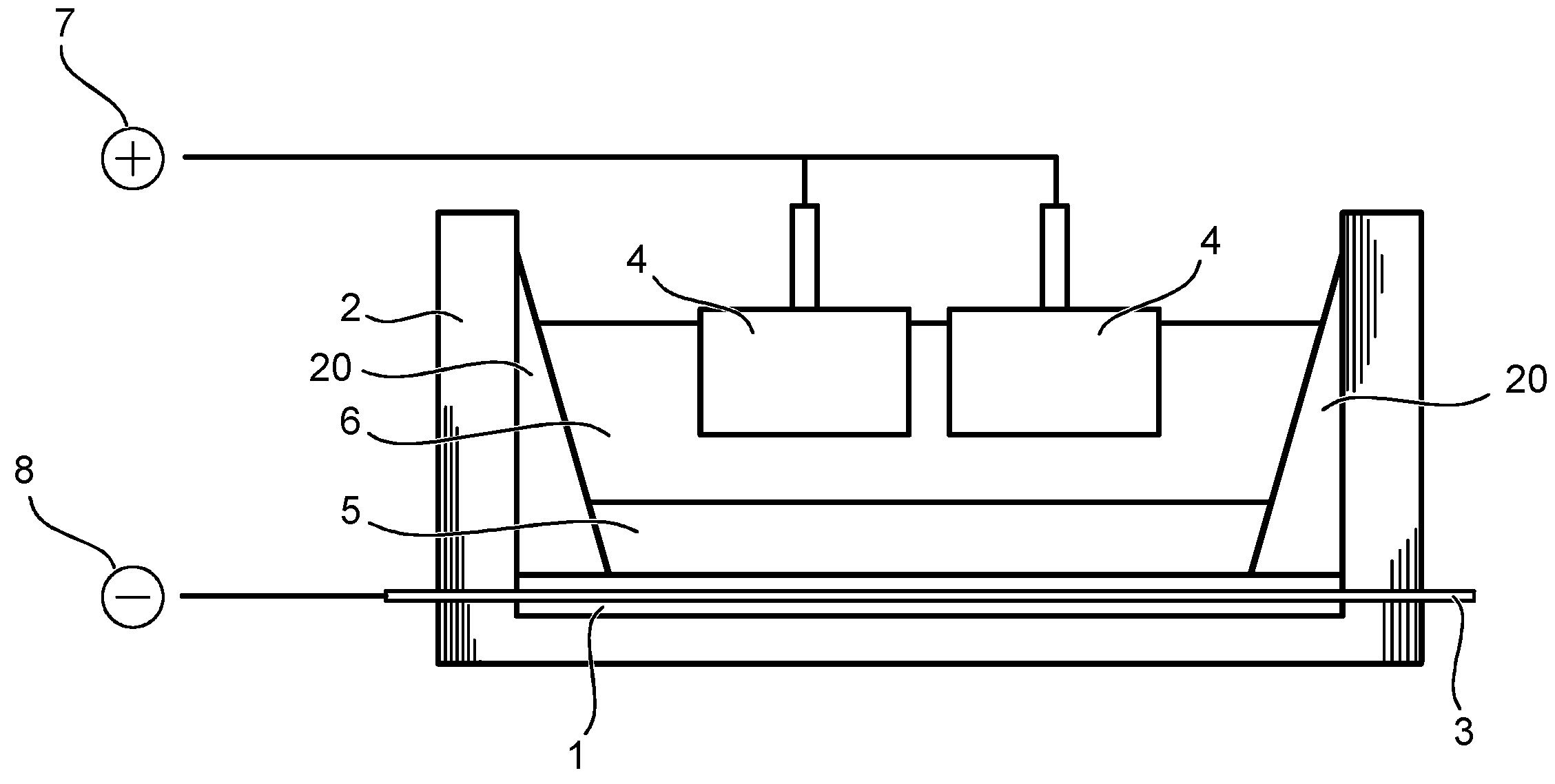

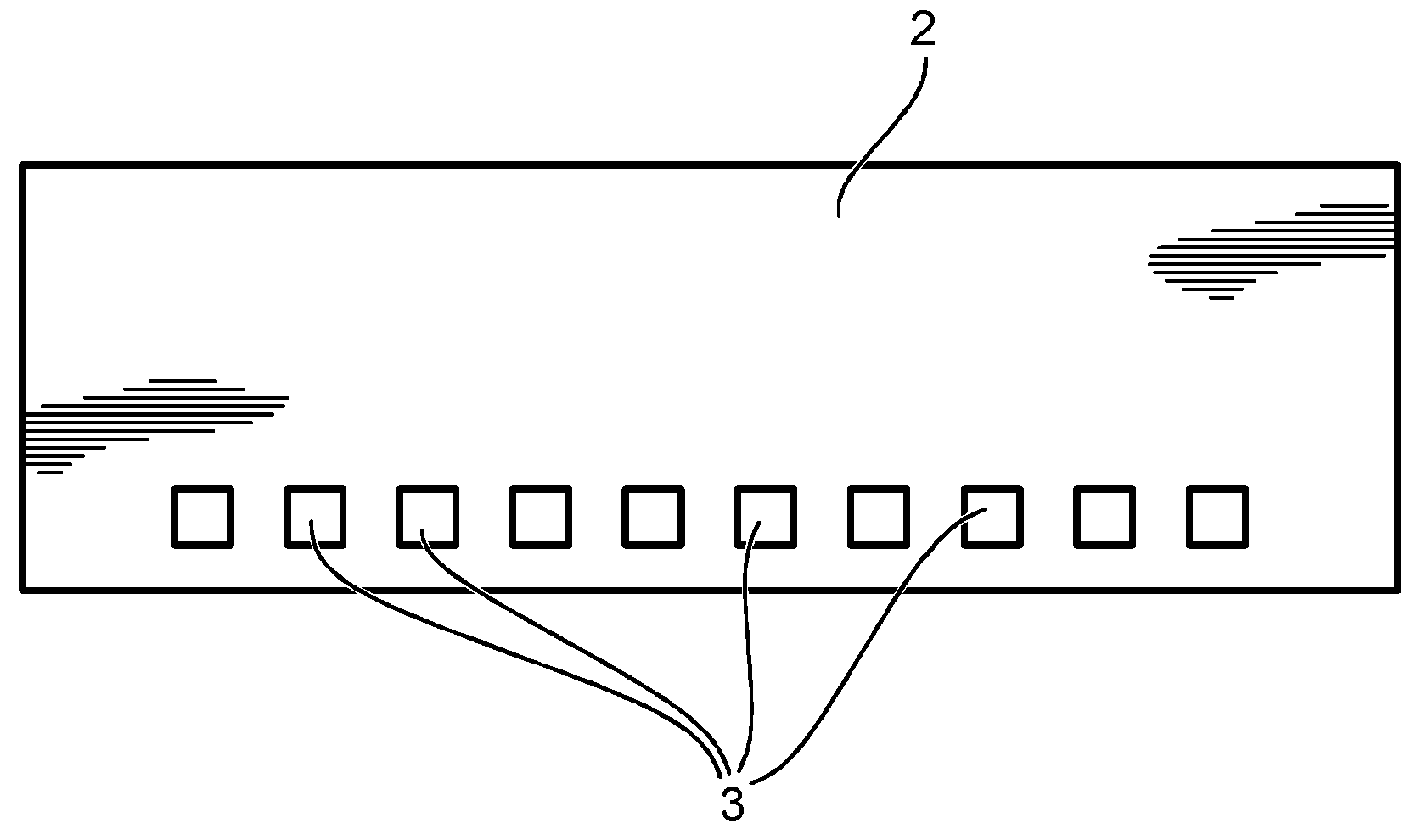

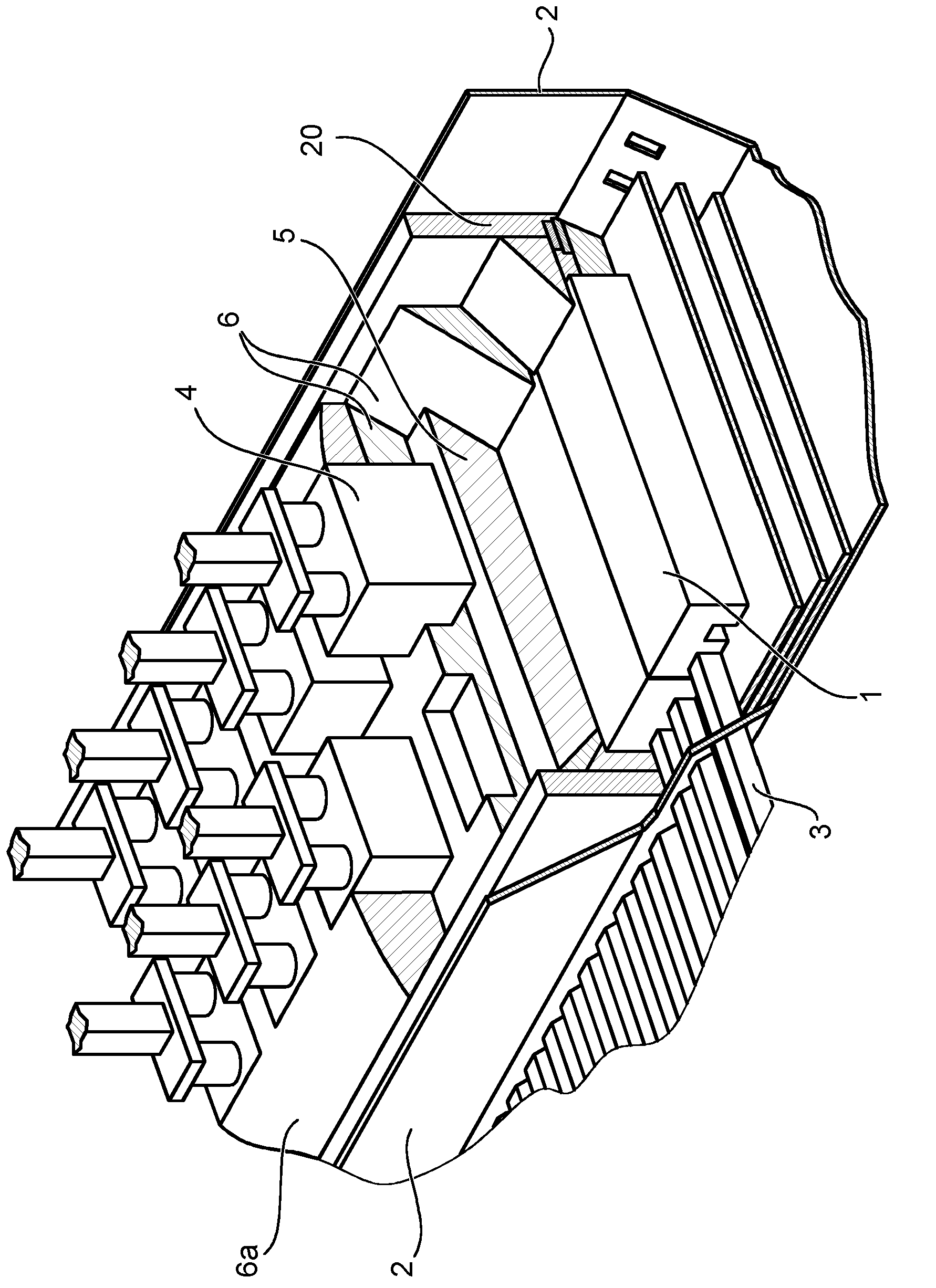

[0037] refer to Figure 2a and 2b , in each case from different perspectives, shows an electrolytic cell with an embodiment of the cathode 1 according to the invention. The cathode 1 shown is suitable for the extraction of aluminum from aluminum oxide using the Hall-Héroult process. In this case, the electrolytic cell is provided with two side walls 1a1 which, together with the bottom wall 1a2, serve to accommodate the electrolyte tank. In the case shown, the side walls 1 a 1 extend along the longitudinal sides of the cathode 1 . The side wall 1a1 is made of individual side wall pieces 1a3. The bottom wall 1a2 represents the upper or first part 1a of the cathode 1 . In this embodiment, the cathode 1 is produced from individual cathode blocks 11 .

[0038] In the exemplary embodiment shown, the lower part 1b of the cathode 1 comprises a plurality of connecting bodies 1b1 formed by trapezoidal bodies 1b2 in the lower part which taper downwards in a V-shape. The connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com