Rear axle regulating nut punching die and punching process

A technology for adjusting nuts and punching punches, applied in punching tools, manufacturing tools, forming tools, etc., can solve the problems of uneven punching and concave gaps, affecting assembly function, and short service life of the mold, and achieves increased guiding effect, The effect of improving product quality and improving mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

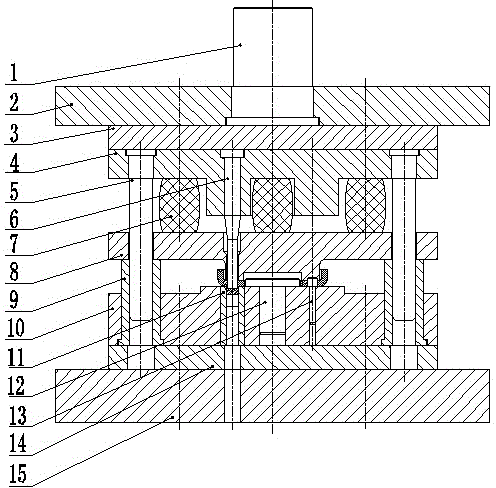

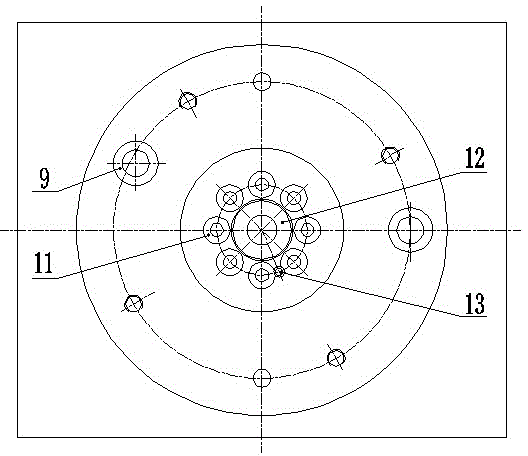

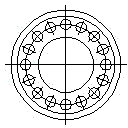

[0032] Example 1: Take the processing of NKR light truck rear axle adjustment nuts as an example:

[0033] NKR light truck rear axle adjustment nut punching 16-hole die structure such as " figure 1 with figure 2 ” shows: The mold is divided into the upper half of the mold and the lower half of the mold.

[0034] The structural relationship of the upper part of the mold is: the punching punch 6 is interference fit with the punch fixing plate 4 according to the design position, the guide post 5 is connected with the punch fixing plate 4 through interference fit, and the punch fixing plate 4 is passed through bolts and positioning pins Installed on the backing plate 3 of the upper mold, the backing plate 3 of the upper mold is installed on the upper template 2 through bolts and positioning pins, the mold handle 1 and the upper template 2 are in interference fit, and the guide plate 8 is connected with the unloading rubber 7 through the unloading bolt. The punch fixed plate 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com