Sizing box for producing PC (poly carbonate) extrusion molding products

A box and water tank technology is applied in the field of cooling and shaping boxes for PC extrusion plastic product molding, which can solve the problems of uneven cooling of profiles, low cooling efficiency, and inability to remove internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

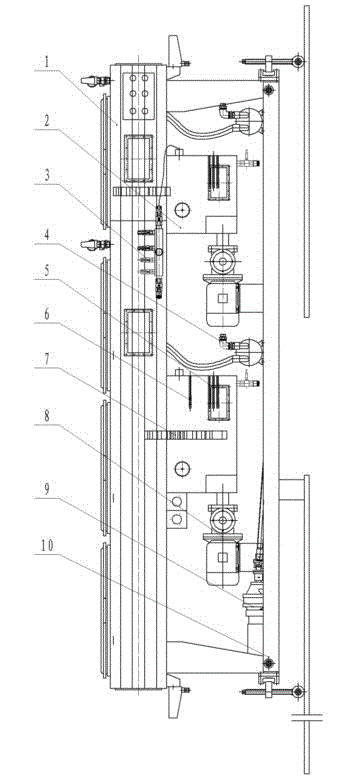

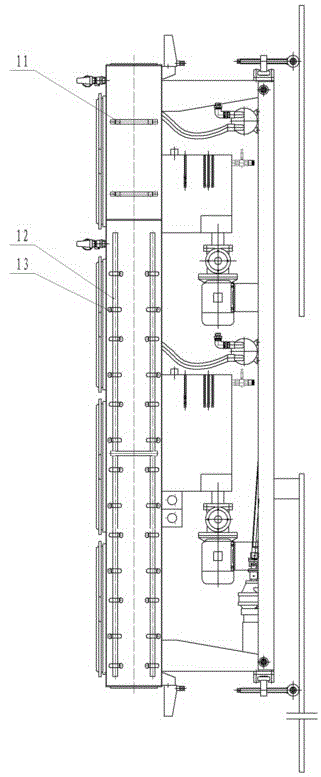

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] The present invention produces PC extruded product and uses stereotypes box such as figure 1 As shown, the box body 1 is fixed on the frame 10, and the moving device 9 is fixed on the frame 10, which can be adjusted up, down, left, right, front and back. The nozzle 13 is evenly fixed on the spray pipe 12, and the spray pipe 12 is evenly distributed around the box to achieve 360-degree full coverage cooling. The water separator A14 is fixed on the box 1, and is connected with each channel The cooling water ring is connected, and a valve is installed on each road, which can realize 11 point-to-point adjustments of each cooling water ring. The cooling water ring 11 is fixed on the box body 1, and several small holes are evenly distributed on the circumference of the cooling water removal ring 11, and are connected with the water separator B3 through a steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com