A refrigeration equipment control system and control method

A technology of refrigeration equipment and control system, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem of no refrigeration system control method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

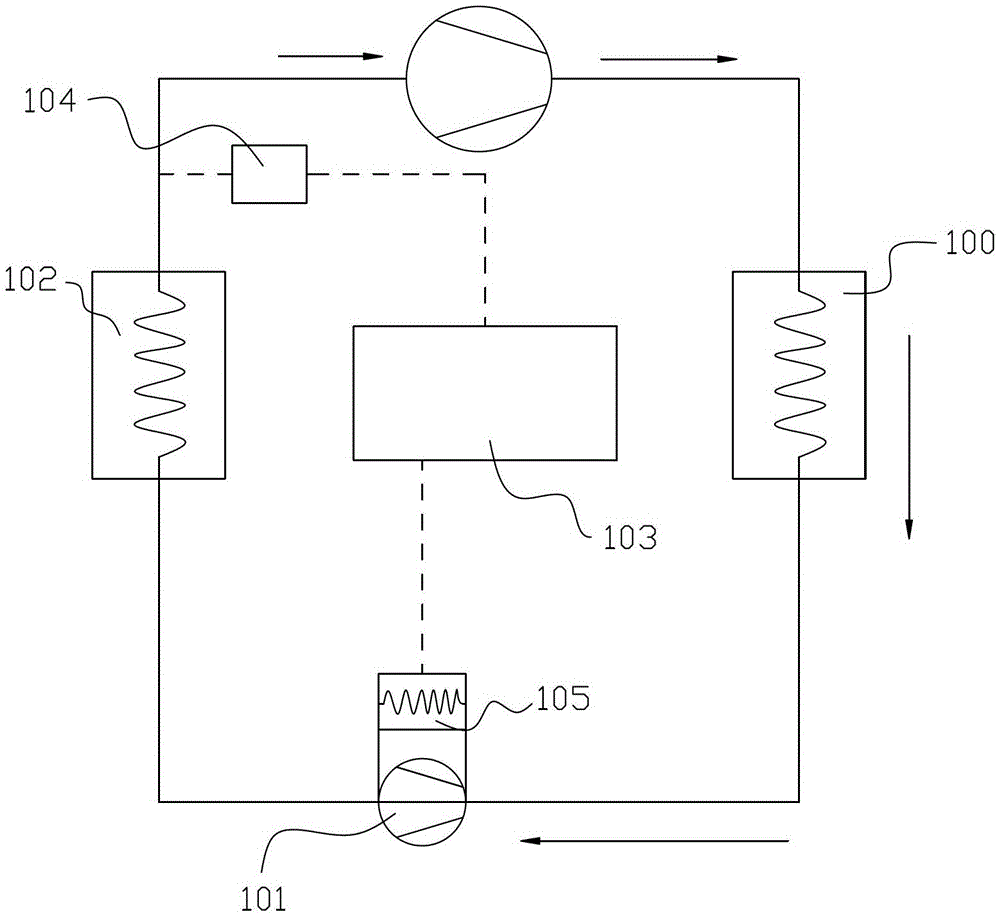

[0050] Such as figure 1 As shown, a refrigeration equipment control system described in this embodiment includes:

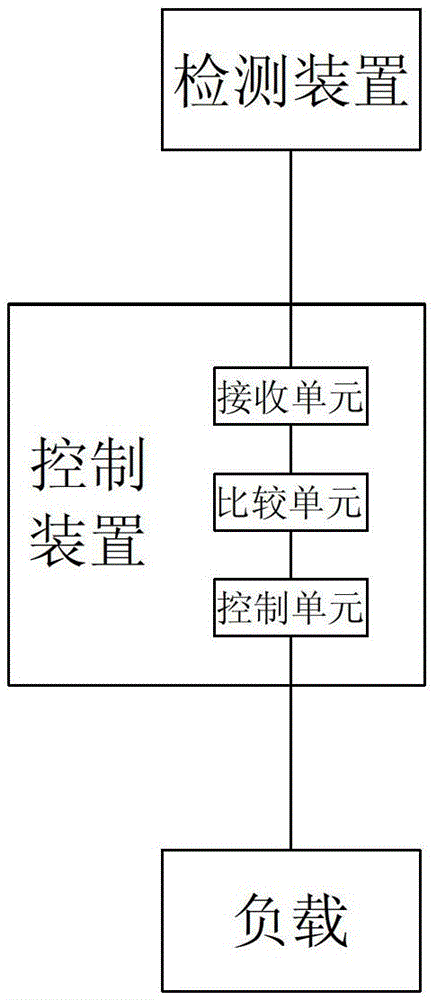

[0051] The control device 103 is connected to the load 105 and connected to the detection device 104 through communication, and is used for receiving the detection result of the detection device 104 and adjusting the load 105 according to the detection result.

[0052] The detection device 104 is arranged in the working circuit of the refrigeration system, and is used to detect the degree of superheat of the evaporator 102 , and communicates with the control device 103 to send the detection result to the control device 103 .

[0053] The throttling expansion device 101 is arranged between the condenser 100 and the evaporator 102, and includes a rotor driven by refrigerant and a stator coil arranged outside the rotor. When the rotor rotates, an induced current is generated in the stator coil, and the rotational speed of the rotor is determined by the stator coil. ...

Embodiment 2

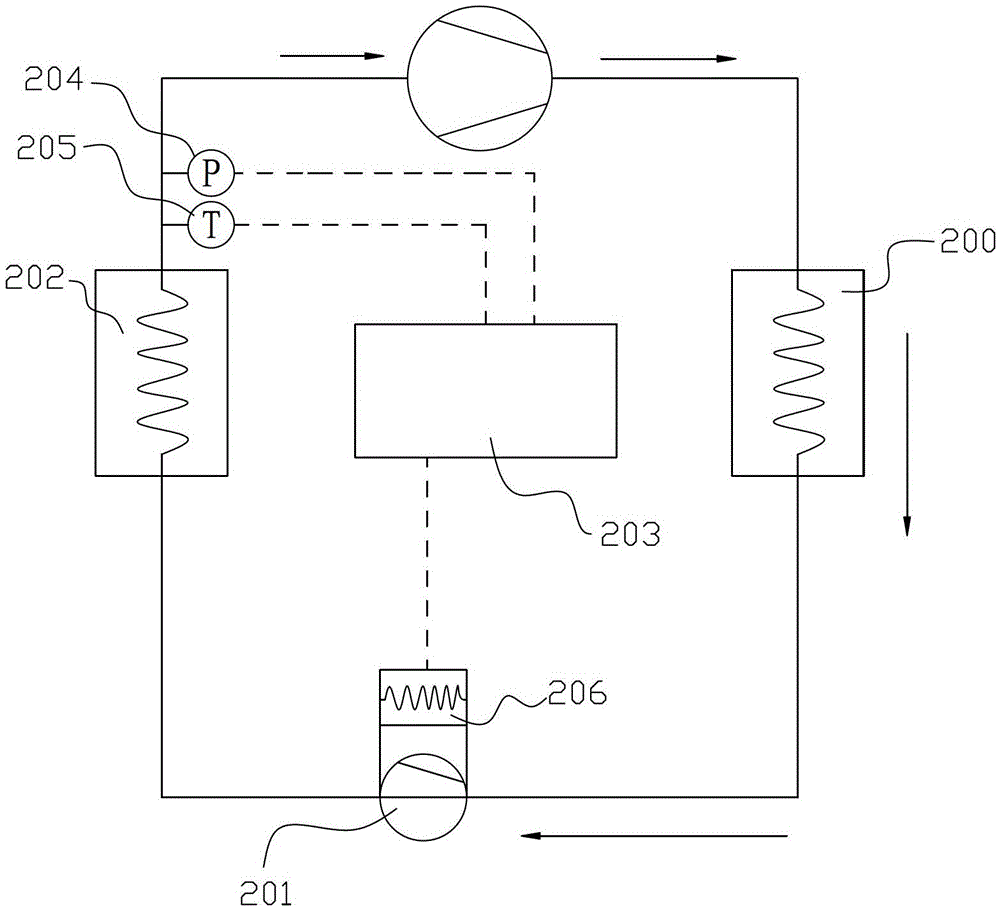

[0056] Such as Figure 2-4 As shown, a refrigeration equipment control system described in this embodiment includes:

[0057]The control device 203 is connected to the load 206 and connected to the detection device through communication, for receiving the detection result of the detection device, and adjusting the load 206 according to the detection result;

[0058] The detection device is arranged in the working circuit of the refrigeration system, and is used to detect the degree of superheat of the evaporator 202, and communicate with the control device 203, and send the detection result to the control device 203;

[0059] The throttling expansion device 201 is arranged between the condenser 200 and the evaporator 202, and includes a rotor driven by refrigerant and a stator coil arranged outside the rotor. When the rotor rotates, an induced current is generated in the stator coil, and the rotational speed of the rotor is determined by the stator coil. Influenced by the cha...

Embodiment 3

[0087] Embodiment three, such as Figure 5 As shown, the difference between the present embodiment and the second embodiment is that the detection device adopted in the third embodiment is composed of three temperature sensors 304, and the three temperature sensors 304 are respectively arranged at the outlet of the condenser 300 and at the end of the evaporator 302. At the inlet and the outlet of the evaporator 302, the control device 303 obtains the degree of superheat of the evaporator 302 through the temperature signals detected by the three temperature sensors 304, compares it with the set degree of superheat, and controls the load 305 according to the comparison result.

[0088] At the same time, in this embodiment, the load 305 adopts an energy recovery device, which is arranged between the condenser 300 and the throttling expansion device 301. The energy recovery device consumes the electric energy provided by the throttling expansion device 301. For example, the load 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com