A hydraulic clutch cooling device

A technology for hydraulic clutches and cooling devices, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of oil pollution, unfavorable hydraulic clutch control, unfavorable protection system key components, etc., to achieve flexible installation position configuration, Promotes magazine precipitation and improves cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

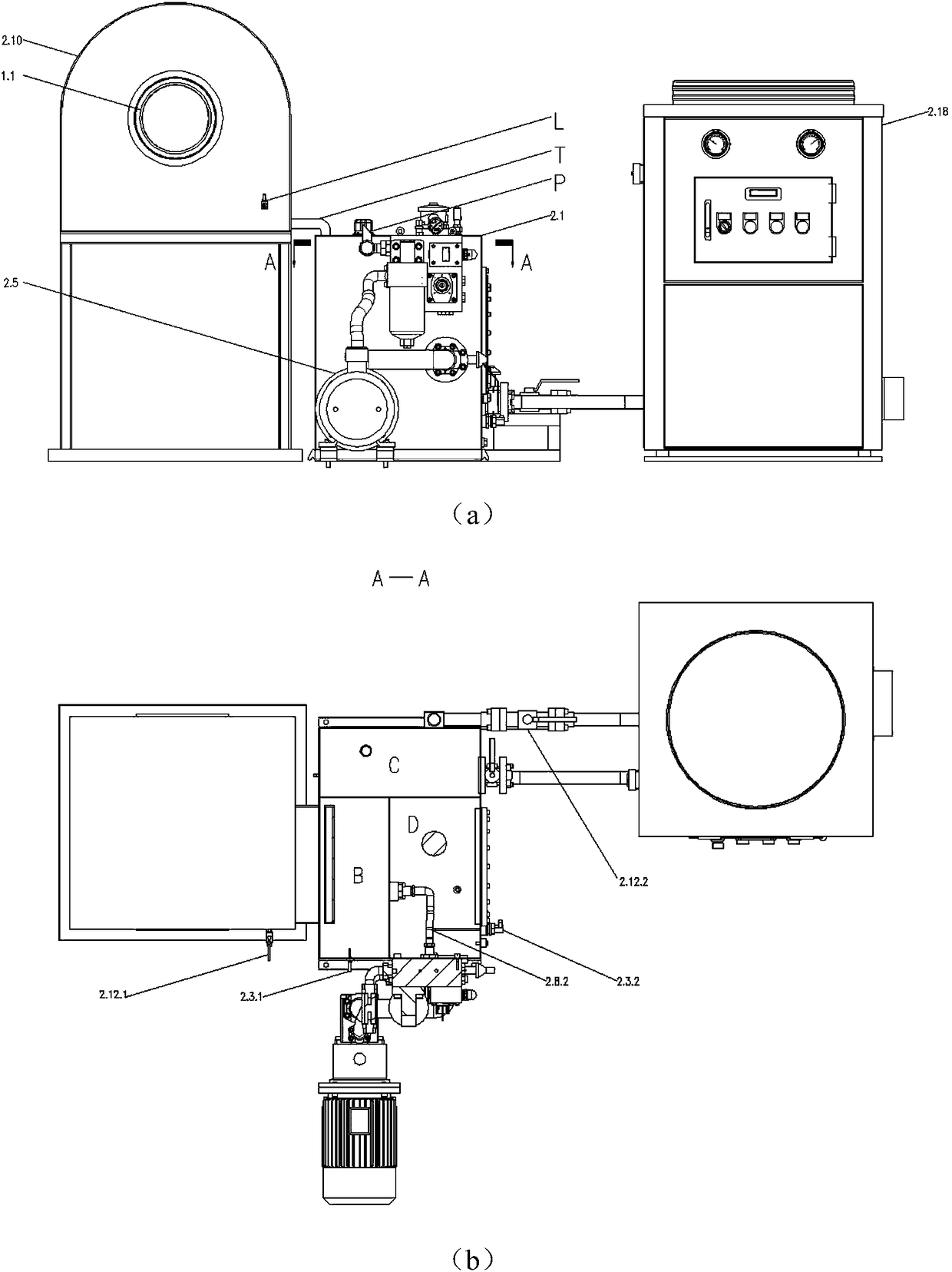

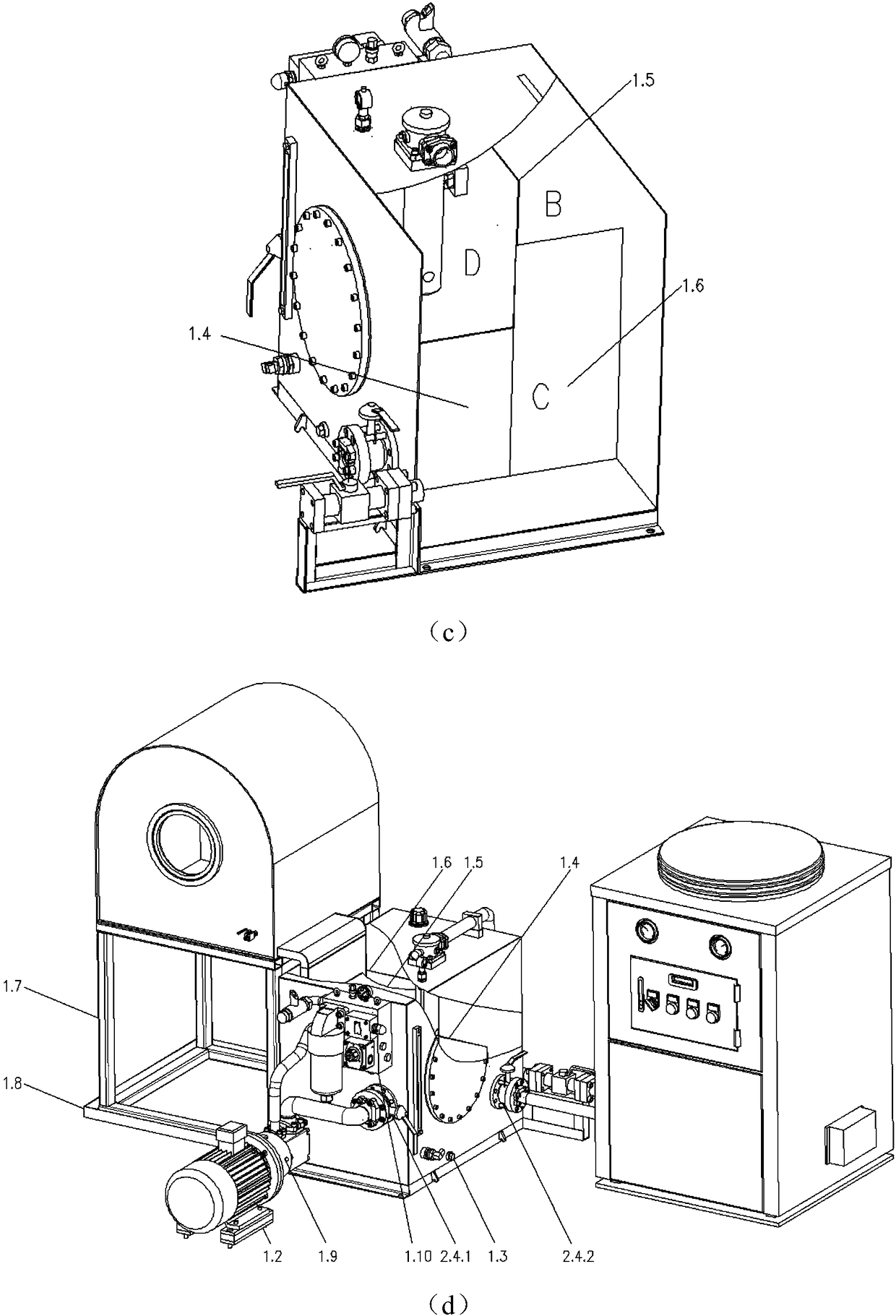

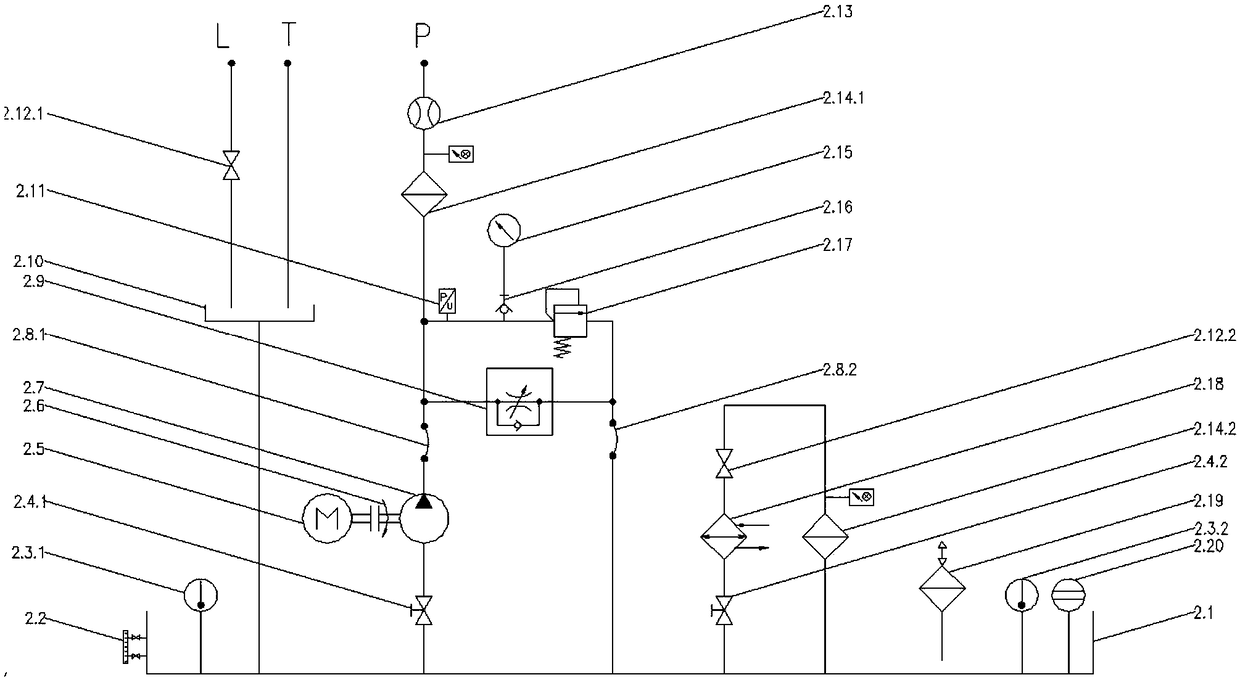

[0026] Embodiment 1: In this embodiment, the device includes a first partition 1.4, a second partition 1.5, a third partition 1.6, a first thermometer 2.3.1, a second thermometer 2.3.2 and a pressure sensor 2.11. The specific working process is as follows:

[0027] The AC motor 2.5 starts, and drives the hydraulic pump 2.7 to work through the shaft coupling 2.6. The hydraulic pump 2.7 draws oil from the oil tank 2.1 through the first butterfly valve 2.4.1, and the oil enters the valve block 1.10 through the first hose 2.8.1. The supplied oil first passes through the one-way throttle valve 2.9, and by adjusting the one-way throttle valve 2.9, the flow rate used to cool the hydraulic clutch can be adjusted to avoid excessive cooling oil pressure, and the excess oil will pass through the second The hose 2.8.2 returns to the fuel tank 2.1. The supplied cooling oil pressure is detected by a pressure sensor 2.11 and a pressure gauge 2.15 installed at the inlet of the one-way throt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com