Manufacturing device for mould pressing combined paper reel

A technology for manufacturing equipment and paper rolls, which is applied in the field of molded board roll manufacturing equipment, can solve the problems of forest resource destruction and environmental protection, and achieve the effect of reducing damage and benefiting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention is further described:

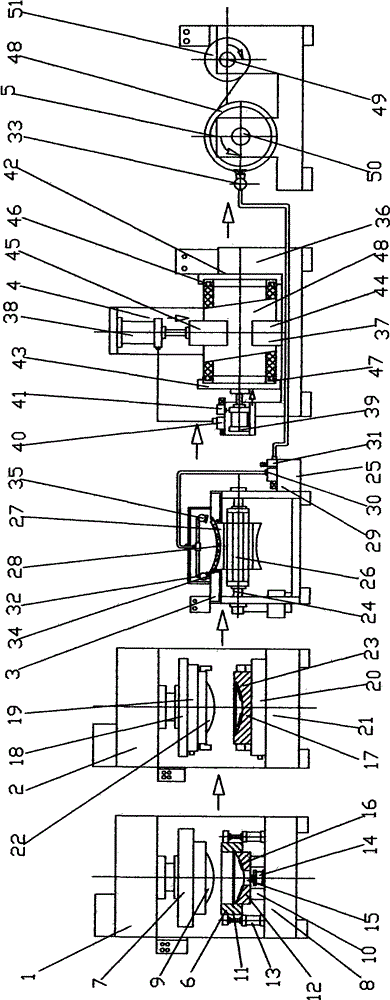

[0010] figure 1 shown figure 1 It is a schematic diagram of the structure of the manufacturing equipment for molded composite paper rolls. The manufacturing equipment for molded composite paper rolls includes a pre-press machine 1, a hot press machine 2, a gluing machine 3, a combination machine 4, and a winding machine 5; 2 is set next to the pre-pressing machine 1, the gluing machine 3 is set next to the heat press 2, the combination machine 4 is set next to the gluing machine 3, and the winding machine 5 is set next to the combination machine 4; the pre-pressing machine 1 includes There is a pre-compression die 6, a pre-compression upper platen 7 and a pre-compression base 8. The pre-compression die 6 includes a pre-compression upper die 9 and a pre-compression lower die 10. The pre-compression lower die 10 includes a movable film frame 11, a pre-compression die Core 12, p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap