High-capacity lining-plate-free solidification molding hacking machine for building blocks

A solidified, large-capacity technology, applied in the stacking, transportation and packaging, packaging and other directions of objects, can solve the problems of limited height of continuous stacking, energy consumption, labor consumption and financial resources of lining investment, etc. The effect of placing, reducing the height of the bricks and eliminating the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

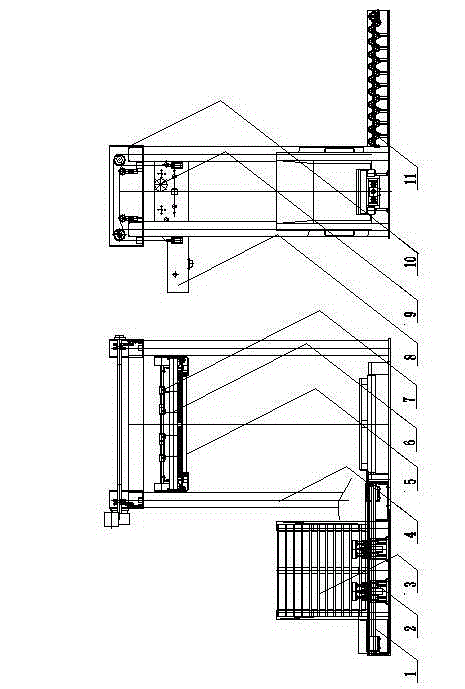

[0009] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment: figure 1 Shown is a large-capacity liner-free curing forming block palletizer of the present invention, which is characterized in that it includes a plate feeding mechanism 1, a pallet lifting device 2, a pallet 3, a main frame 4, a rolling platform 5, Guide device 6, brick clamping device 7, moving frame 8 up and down, translation transmission device 9, main frame upper frame 10 and conveying platform 11, described feeding mechanism 1 is arranged on the outer end of described main frame 4, and described supporting plate lifts The lifting device 2 is arranged in the middle of the plate feeding mechanism 1. After the pallet lifting device 2 lifts the pallet 3, the plate feeding mechanism 1 will lift the bottom pallet 3 It is sent to the stacking position and is in a state of waiting for stacking; in the process of continuous automatic production, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com