Method for preparing manganese and nickel co-doped bismuth ferrite film by sol-gel process

A technology of co-doping and bismuth ferrite, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of complicated steps, optical and magnetic properties, etc., and achieve simple steps, low equipment cost, and reduce optical The effect of the bandgap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

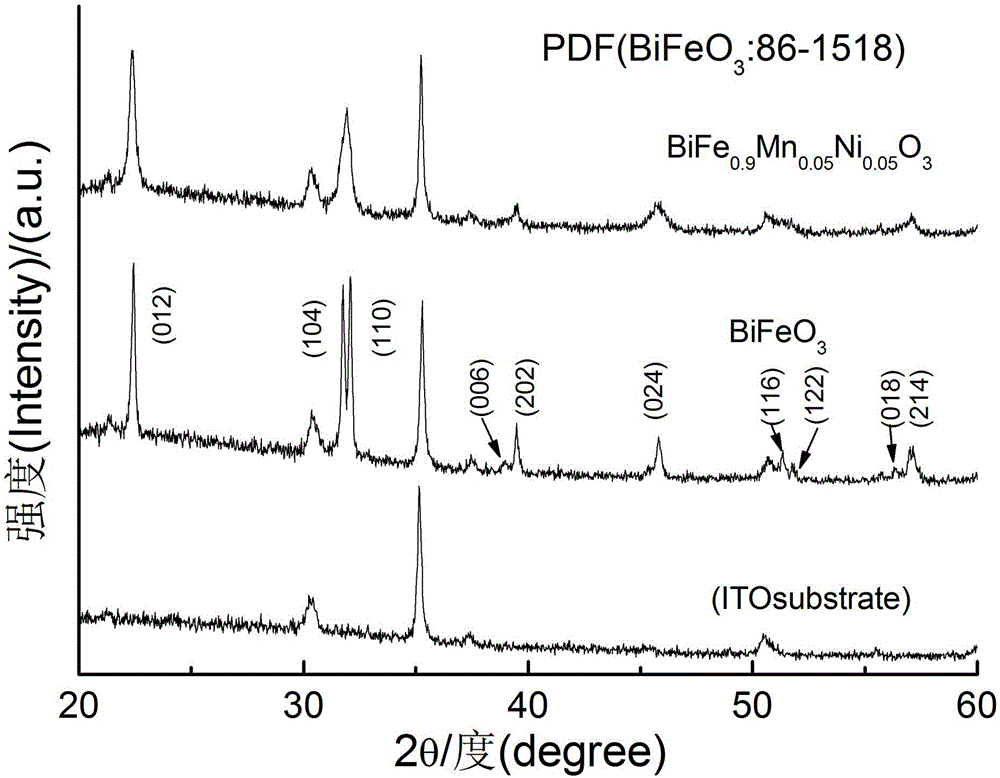

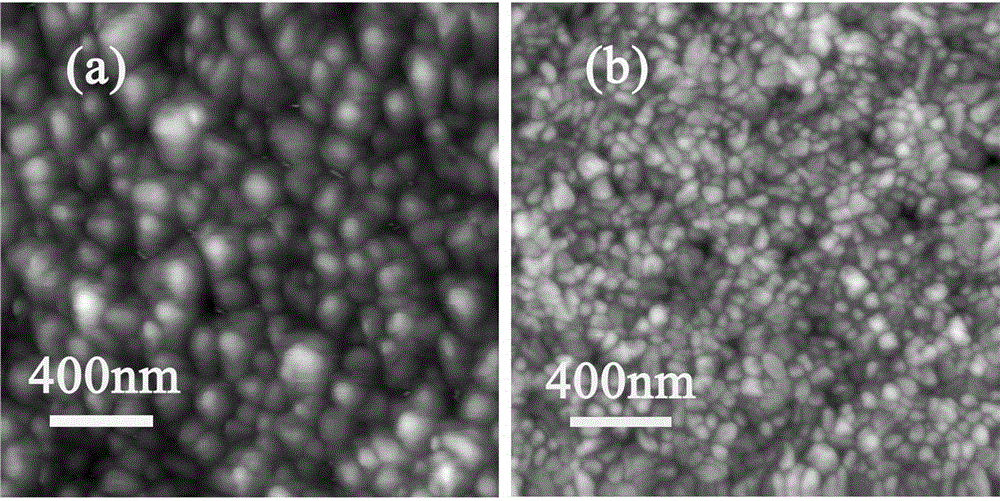

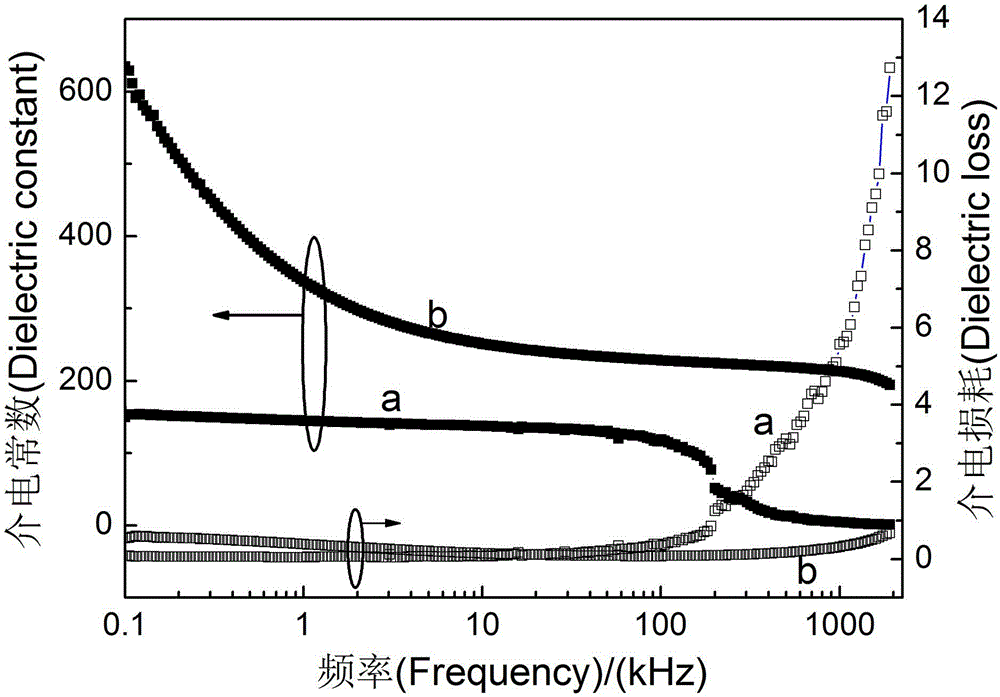

[0020] a, the raw materials ferric nitrate, bismuth nitrate, manganese acetate and nickel acetate, according to formula BiFe 1-2x mn x Ni x o 3 , x=0.0125 for weighing. Add glacial acetic acid and stir at 80°C for 30 minutes, then add ethylene glycol methyl ether and stir at room temperature for 180 minutes to prepare a precursor solution with a concentration of 0.1mol / L;

[0021] b. Spread the precursor solution on the platinum substrate at a speed of 3000r / min for 20s to prepare a wet film;

[0022] c. Pre-anneal the wet film at 350°C for 5 minutes, then anneal at 550°C for 30 minutes;

[0023] d. Repeat step c 20 times to obtain the final sample.

Embodiment 2

[0025] a, the raw materials ferric nitrate, bismuth nitrate, manganese acetate and nickel acetate, according to formula BiFe 1-2x mn x Ni x o 3 , x=0.025 for weighing. Add glacial acetic acid and stir at 80°C for 30 minutes, then add ethylene glycol methyl ether and stir for 180 minutes at room temperature to prepare a precursor solution with a concentration of 0.2mol / L;

[0026] b. Spread the precursor solution on the indium tin oxide / glass substrate at a speed of 3000r / min for 20s to prepare a wet film;

[0027] c. Pre-anneal the wet film at 350°C for 5 minutes, then anneal at 550°C for 30 minutes;

[0028] d. Repeat step c 10 times to obtain the final sample.

Embodiment 3

[0030] a, the raw materials ferric nitrate, bismuth nitrate, manganese acetate and nickel acetate, according to formula BiFe 1-2x mn x Ni x o 3 , x=0.0375 for weighing. Add glacial acetic acid and stir at 80°C for 30 minutes, then add ethylene glycol methyl ether and stir for 180 minutes at room temperature to prepare a precursor solution with a concentration of 0.15mol / L;

[0031] b. Spread the precursor solution on the indium tin oxide / glass substrate at a speed of 3000r / min for 20s to prepare a wet film;

[0032] c. Pre-anneal the wet film at 350°C for 5 minutes, then anneal at 550°C for 30 minutes;

[0033] d. Step c was repeated 13 times to obtain the final sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com